1-12

99T-M12M0-0107-0

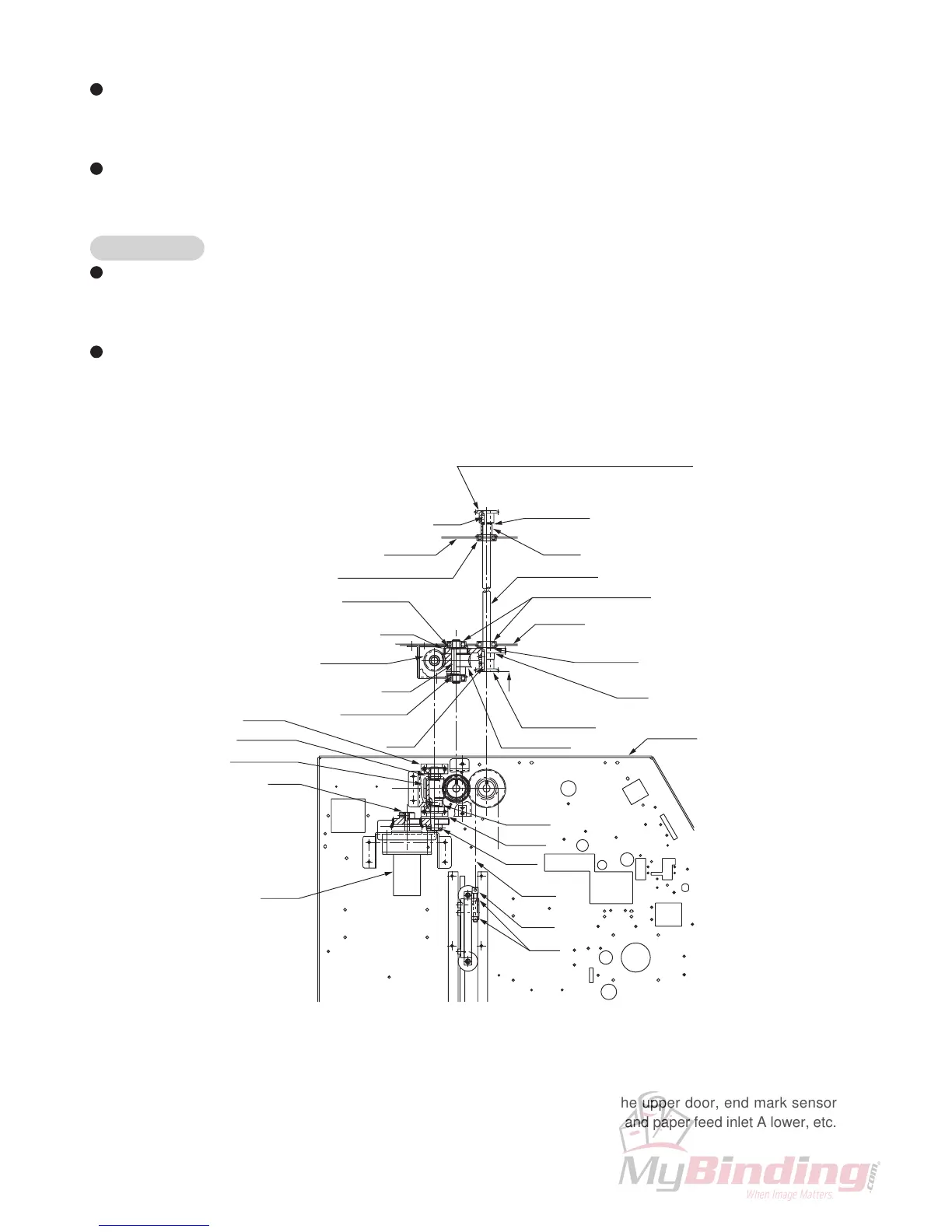

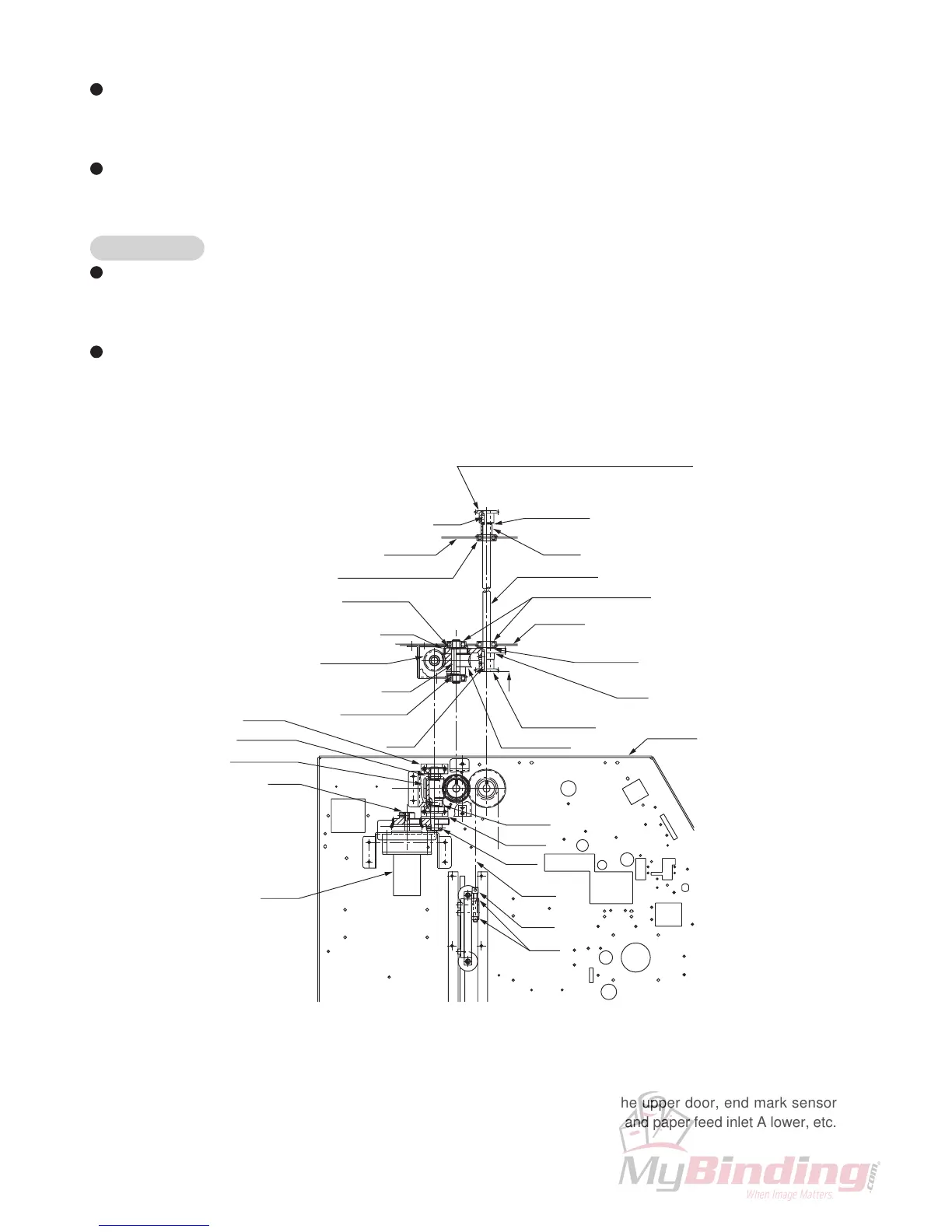

3-3. Paper Feed Tray Up and Down Section

The paper feed tray is raised and lowered by the rotation of the sprocket of the up/down shaft and the pulling of the

paper feed tray by the chain. The other chain is a spring which pulls the paper feed tray in the rising direction at all

times. The up/down shaft is driven using a DC motor and decelerated by a worm gear.

When the paper feed tray moves up, the position of the tray is detected with the actuator of the level sensor and the

tray stops at the detected position. When the tray moves down, the tray touches the microswitch (lower limit switch

A), and the tray stops at the position.

Adjustments

Adjust the position of the lower limit switch unit A to determine the lower limit position of the paper feed tray.

To maintain a clearance of 217 to 223 mm (8.54" to 8.78") between the paper feed tray and suction belt when the

paper feed tray is at the bottommost position, adjust the attaching position of the lower limit switch unit A.

Adjust the parallelity of the paper feed tray using the nuts attached to the left and right joints.

Loosen the top nut once, adjust the height of the paper feed tray using the bottom nut, and then tighten the top nut

to secure. If the paper feed tray does not become parallel, the chain and sprocket of the up/down shaft may not be

engaged properly. Engage properly and then adjust.

3-4. Greasing the Secondary Conveyance Roller of the Paper Feed Section

This roller is pre-greased. When the grease runs out, a whistle-like buzzer is sounded.

To reach the secondary conveyance roller with the hand for greasing, remove the upper door, end mark sensor

(upper), double-feed detection sensor, conveyance shaft, paper feed inlet A upper, and paper feed inlet A lower, etc.

Holder

2 washers

96G-1124X

12N sprocket

Key

Key

Gear

Gear

Gear

Worm gear

Worm wheel

Washer

96G-1124X

Gear

12N sprocket

Key

Oil seal

Holder

Chain

Joint

Nuts

Set collar

Worm gear

Even

Collar

Frame F

Frame B

Frame B

Up/down shaft

Bearing (6201ZZNR)

Bearings (6201ZZNR)

Washer

96G-1124X

Washer

96G-1124X

(Fix so that movement of shaft is between

0.2 to 0.5 mm (0.008" to 0.02"))

Motor

Loading...

Loading...