1-30

99T-M12M0-0107-0

14. MAINTENANCE

Clean the following parts

Conveyance roller, suction belt

(Refer to “12. STRUCTURE OF CONVEYANCE ROLLERS AND CONVEYANCE GUIDES”.)

Reversal clutch (Refer to “5-2. Replacing the Clutch”.)

Following sensors:

Double-feed detection sensor (Refer to Non-operating side in “1-3. Positions of Main Parts”.)

End mark detection sensor (Refer to “9-4. Cleaning”.)

No-paper detection sensor (Refer to “3-1, 4-1. Detection of No-paper”.)

Index sensor (Refer to Non-operating side in “1-3. Positions of Main Parts”.)

Reversal sensor (Refer to “5. REVERSAL SECTION”.)

Inside the machine

Remove the frame B side plate and clean off the paper bits inside.

(Refer to Non-operating side in “1-3. Positions of Main Parts”.)

Grease the following parts (Equivalent to Kyodoyushi Co. Ld. uniloob No.2)

Chain, sprocket (Refer to “3-3. Paper Feed Tray Up and Down Section”.)

Gear section (Refer to “3. PAPER FEEDER A”, “4. PAPER FEEDER B”, “5. REVERSAL SECTION”,

and gears on all other driving sections.)

Solenoid valve section (Refer to “2-3. Solenoid Valve”.)

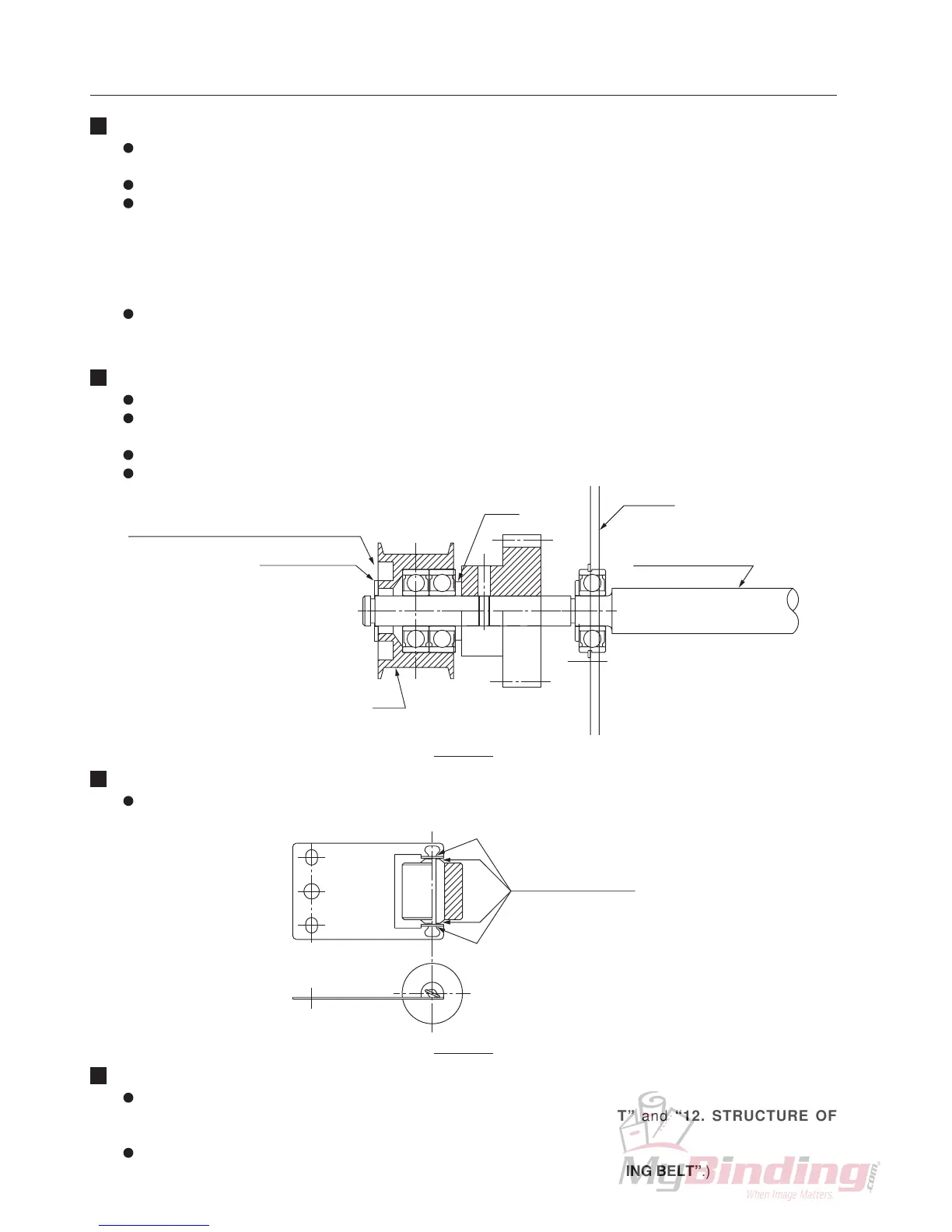

Between idler and adjusting washer (Refer to Figure A.)

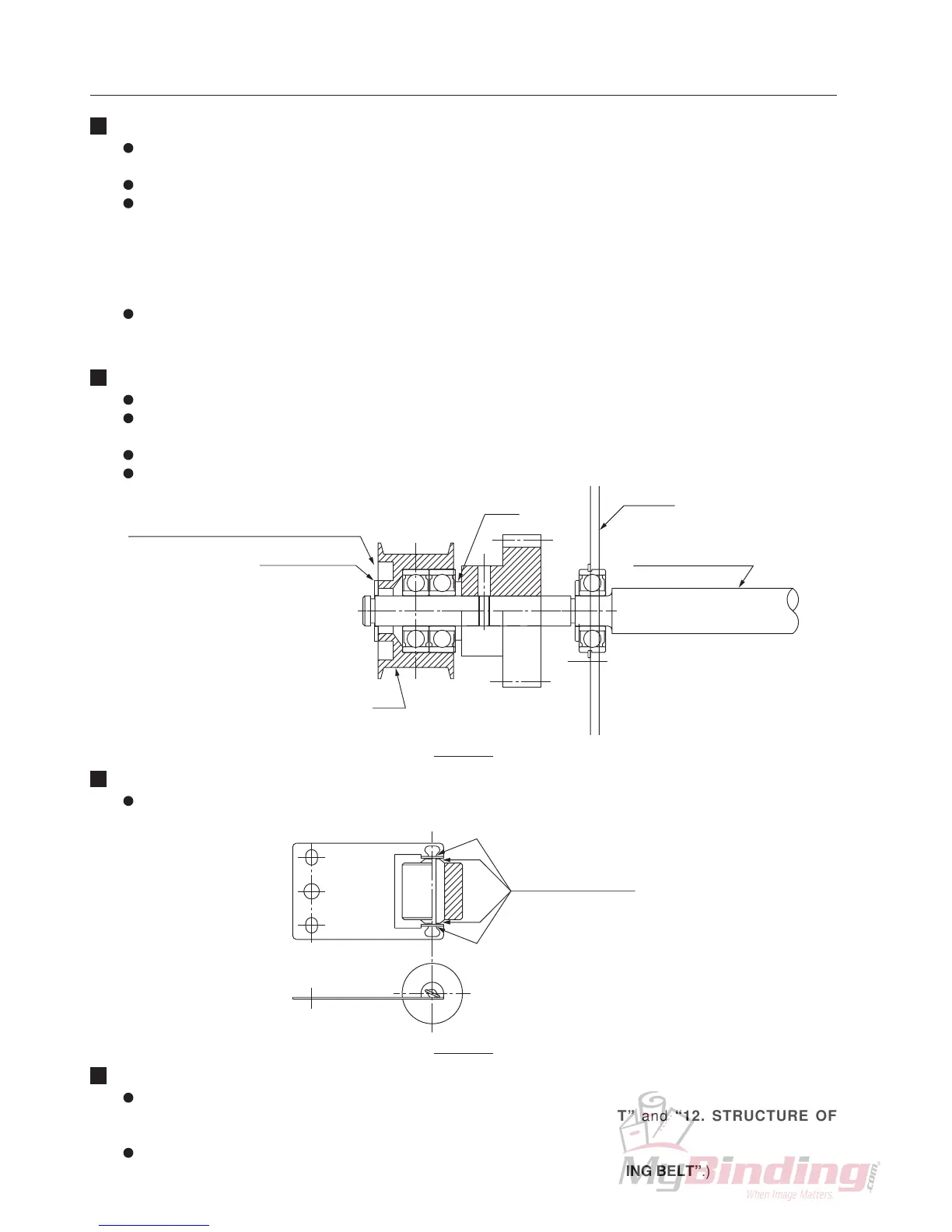

Grease the following parts (Equivalent to Dowconning Co. Ld. MOLY KOTE X5-6020)

Shaft of secondary conveyance roller

(Refer to “12. STRUCTURE OF CONVEYANCE ROLLERS AND CONVEYANCE GUIDES” and Figure B.)

Figure A

Oil the following parts (Equivalent to Nisseki Mitsubishi Co. Ld. FBK oil R028)

Sintering bearings of driving section and conveyance section

(Refer to “11. ADJUSTING THE TENSION OF THE TIMING BELT” and “12. STRUCTURE OF

CONVEYANCE ROLLERS AND CONVEYANCE GUIDES”.)

Sliding part of tension roller (black)

(Refer to Operating side in “11. ADJUSTING THE TENSION OF THE TIMING BELT”.)

Figure B

Frame B

Reversal roller shaft 1

Adjusting washer

Idler

Grease between idler and adjusting washer

t1 × 8 × 16

M8W

Apply grease the shaft

(92T-4010X)

Loading...

Loading...