42 | www.eddy.com

Using Reddy with Sharck Probes

Analyzing Data

Available C-Scans

There are ve available C-scans in the Sharck probe setups:

• Depth Raw C-Scan (raw data without processing, showing depth view — axial)

• Depth Short C-Scan (depth view — axial, compensated and ltered)

• Depth Long C-Scan (depth view — axial, compensated)

• Length C-Scan (length view — axial, ltered)

• Transverse C-Scan (depth view — transverse, ltered)

The same channels are used in the Depth Short and Depth Long C-scans, but different processes are

applied to them. A median lter is applied to the Depth Short C-scan to reduce the noise induced by

the state of the surface under test or by the weld. The main drawback of this lter is that it tends to

“cut” long defects. This is why we recommend using the Depth Long C-scan to assess aws longer than

25 mm (1 in).

We also strongly recommend that you visualize the Depth Raw C-scan rst to determine whether to

use the Depth Long or Depth Short C-scan to assess aws, thus avoiding missing defects. This C-scan

also helps position the weld on the scan and assess the presence of permeability variations.

Analysis Methodology

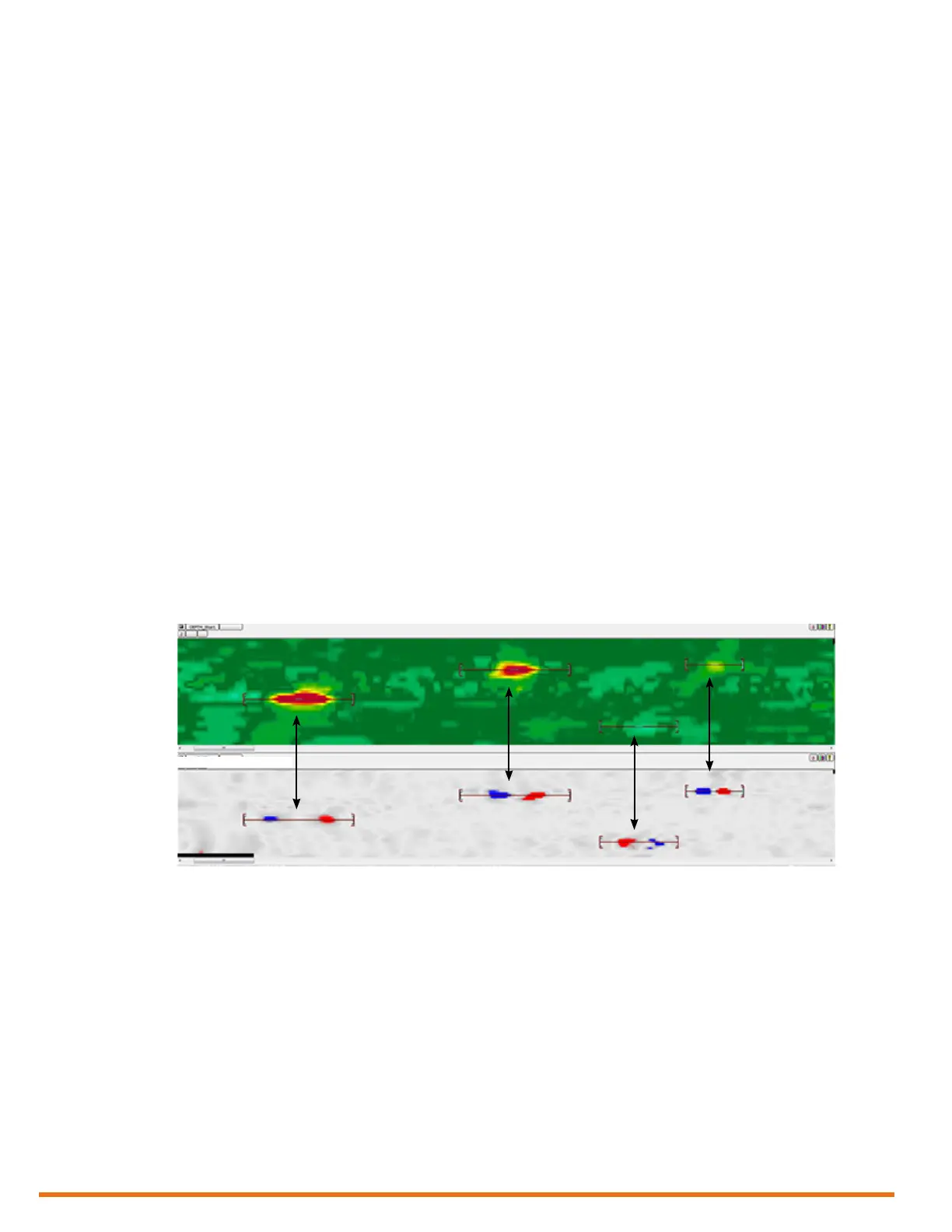

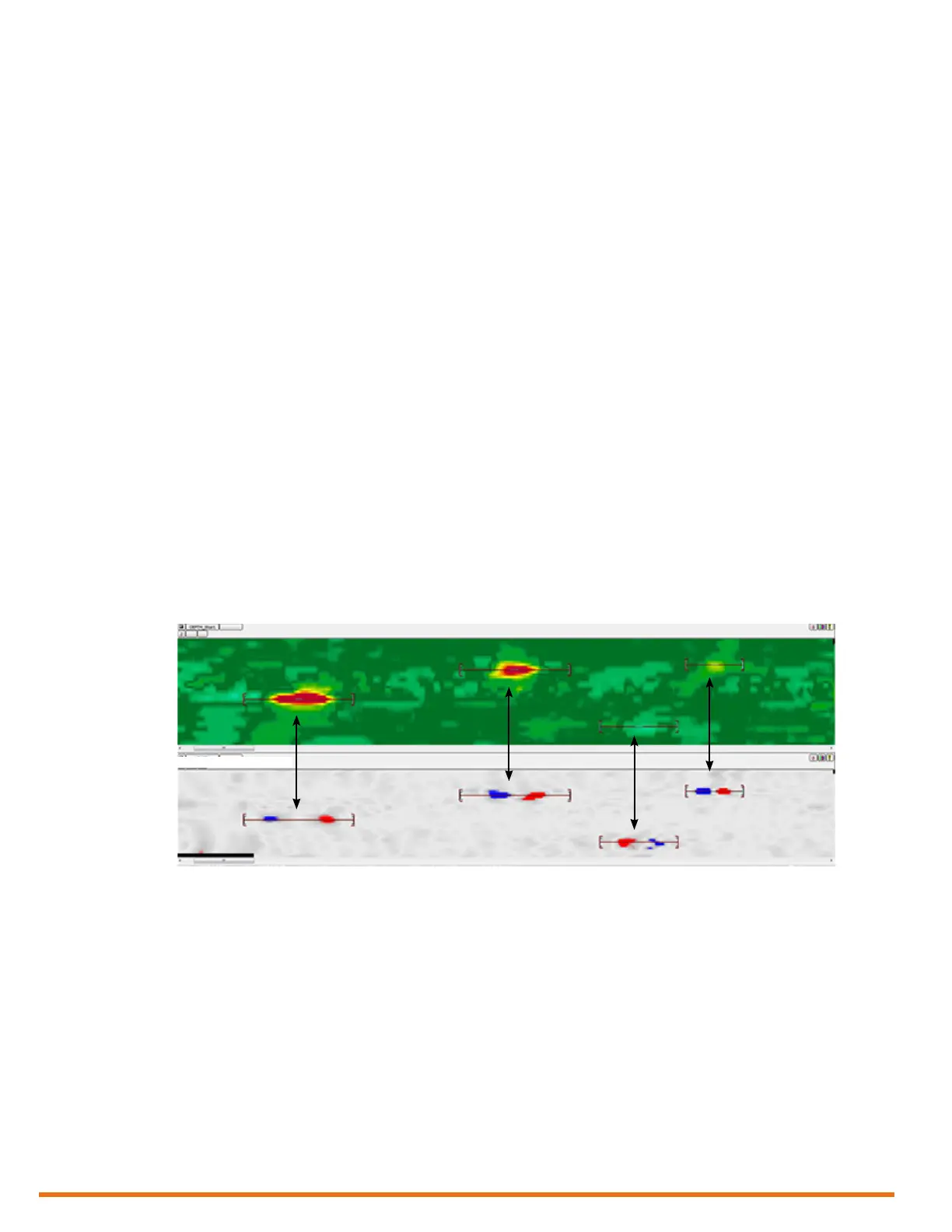

Data is analyzed by reviewing the Depth Short or Depth Long and the Length C-scans. Flaw-like

indications are characterized by the presence of bright spots on the Depth C-scans and two aligned spots

(opposed colors in the palette) in the Length C-scan (representing a differential signal visualized on the

impedance plane) at the same location, aligned on both axes of the cursor.

Figure 5–29 Flaw-like and spurious indications

When aw-like indications are detected, you must isolate them with the cursor to obtain the sizing

information (depth, length, liftoff, and position). Place your cursor over an indication and maximize the

signal in the impedance plane view of the Depth C-scan you are using, while making sure that you keep

both extremities of the defect within the cursor in the Length C-scan.

In the Length C-scan, resize your cursor horizontally so that it contains the entire indication (the

aperture of the cursor should be equal to the measured length plus 15 mm (0.59 in), which corresponds

to the each of the probe’s elements). All measurements are made automatically and appear on the Reddy

display.

Defect-like indication

Defect-like indication

Defect-like indication

Spurious indication caused by

unaligned geometrical signals

inverted in Length C-scan

Loading...

Loading...