Safety

Information

Introduction Installation

PowerTools

Pro Software

Communications

How

Motion

Works

How I/O

Works

Configuring

an

Application

Programming

Starting and

Stopping

Motion

Starting and

Stopping

Programs

Parameter

Descriptions

Drive

Parameters

Used by

EZMotion

Diagnostics Glossary Index

EZMotion User/Programming Guide 77

Revision A8 www.controltechniques.com

This scaling factor is as follows:

Scaling - Characteristic Distance

This parameter is the distance the load travels (in user units) when the motor travels the characteristic length (in motor

revolutions). This parameter is used along with the DistUnits.CharacteristicLength to establish the relationship between user

distance and actual motor travel distance.

Scaling - Characteristic Length

This parameter is the distance the motor travels (in whole number of revolutions) to achieve one characteristic distance of load

travel. This parameter is used along with the DistUnits.CharacteristicDist to establish the relationship between user distance

and motor travel distance.

Velocity

Time Scale List Box

The time can be one of two values: seconds or minutes. This selection sets the real-time velocity time scale.

Decimal Places

The number of decimal places defined in this parameter determines the max resolution of all real-time velocity parameters

found throughout the PowerTools Pro software. Set between 0 and 6 decimal places. Higher number of decimal places allows

higher velocity resolution, but can limit the max speed allowed by the application.

Acceleration

Time Scale List Box

From this list box, select the acceleration time scale to be used for all real-time profiles. The time scale selected will be used

for both acceleration and deceleration parameters. You can select from milliseconds or seconds.

Decimal Places

The number of decimal places defined in this parameter determines the max resolution of all real-time acceleration and

deceleration parameters found throughout the software. Set between 0 and 6 decimal places.

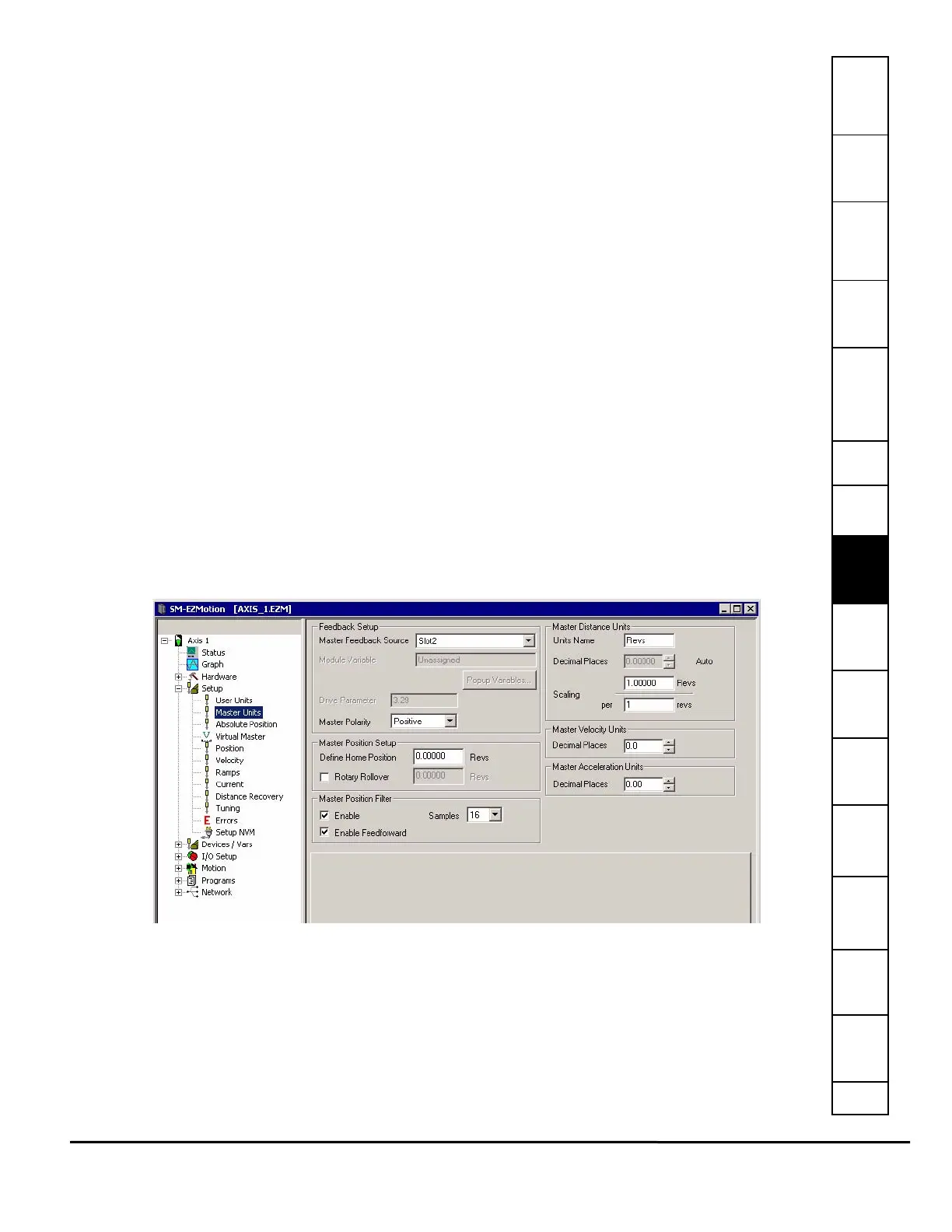

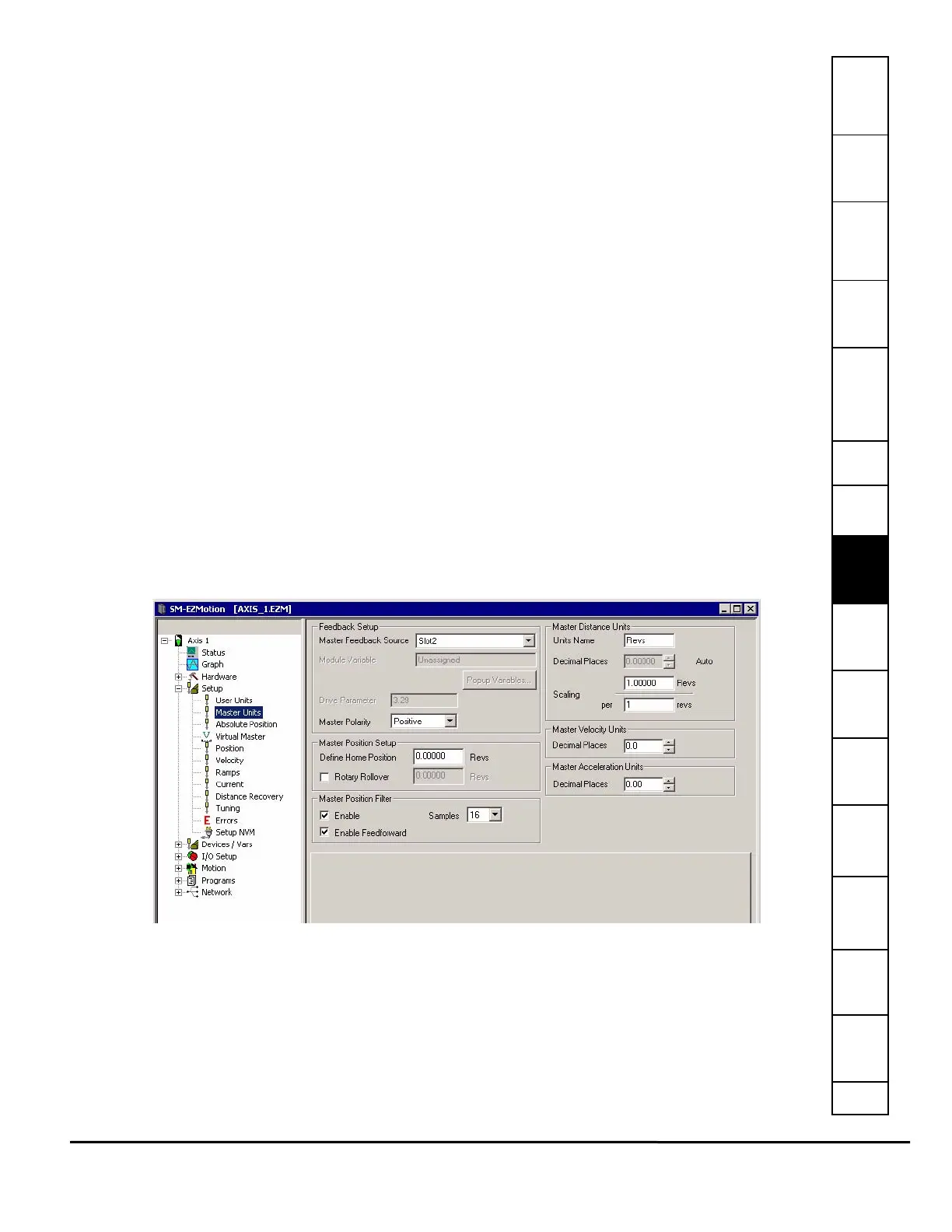

8.4.3 Master Units View

The Master Units view is used to configure the parameters for the master axis used in synchronized motion applications. The

master axis is most often a second encoder, or possibly another upstream drive. Figure 82 shows an example of the Master

Units view.

Feedback Setup

Figure 82: Master Units Setup View

Master Feedback Source

Master Feedback Source indicates the source of the master encoder input. Select from Drive, Slot 1, Slot 2 or Slot 3. If Drive

is selected, then that means that the motor feedback must be routed to one of the option module slots.

Select User Defined Drive Parameter, the Drive Parameter text box will become available to enter the drive parameter that will

be the source of the master.

Select User Defined Module Parameter, the Module Variable text box will become available to enter a parameter. The module

variable can be entered two ways: type the parameter into the text box using the program format for the variable, or click the

Popup Variables button and the Select Variables from Tree window will open. Select the variable and drag it over to the

Module Variable text box.

Scaling

Characteristic Distance

Characteristic Length

------------------------------------------------------------------=

Loading...

Loading...