Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running

the motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL listing

information

128 Unidrive M702 User Guide

Issue Number: 3

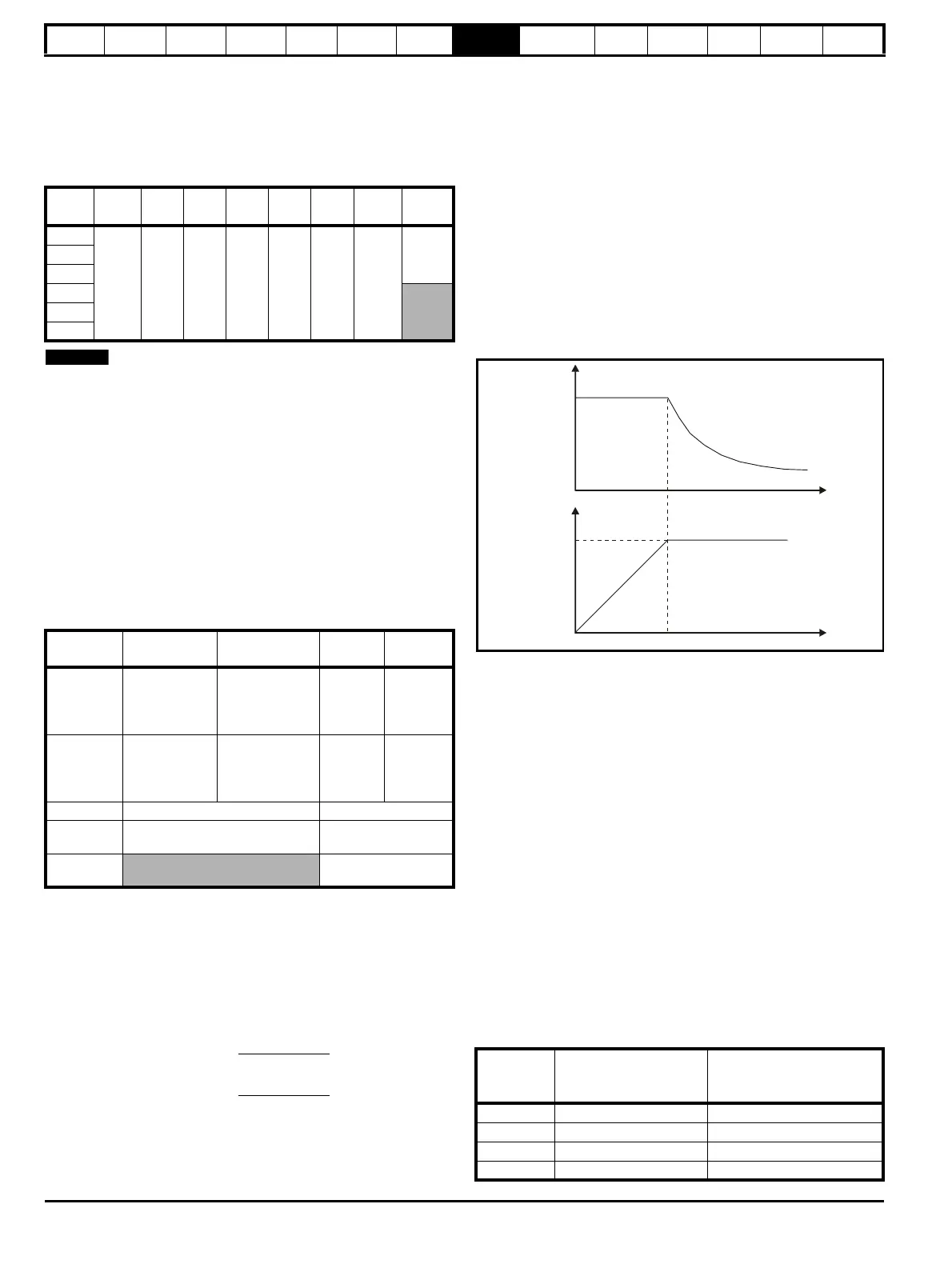

8.5 Switching frequency

The default switching frequency is 3 kHz (6 kHz in RFC-S mode),

however this can be increased up to a maximum of 16 kHz by Pr 05.018

(dependent on drive size). The available switching frequencies are

shown below.

Table 8-1 Available switching frequencies

* Size 5 - 575 V variant does not support 16 kHz switching frequency.

If switching frequency is increased from 3 kHz the following apply:

1. Increased heat loss in the drive, which means that derating to the

output current must be applied.

See the derating tables for switching frequency and ambient

temperature in section 12.1.1 Power and current ratings (Derating

for switching frequency and temperature) on page 227.

2. Reduced heating of the motor - due to improved output waveform

quality.

3. Reduced acoustic noise generated by the motor.

4. Increased sample rate on the speed and current controllers. A trade

off must be made between motor heating, drive heating and the

demands of the application with respect to the sample time required.

Table 8-2 Sample rates for various control tasks at each

switching frequency

8.6 High speed operation

8.6.1 Encoder feedback limits

The maximum encoder frequency should be prevented from exceeding

500 kHz. In RFC-A and RFC-S modes the maximum speed that can be

entered in to the speed reference clamps (Pr

01.006

and Pr

01.007

) can

be limited by the drive. This is defined by the following (subject to an

absolute maximum of 40,000 rpm):

Where:

ELPR is the equivalent encoder lines per revolution and is the

number of lines that would be produced by a quadrature encoder.

• Quadrature encoder ELPR = number of lines per revolution

• F and D encoder ELPR = number of lines per revolution / 2

• SINCOS encoder ELPR = number of sine waves per revolution

This maximum speed limit is defined by the device selected with the

speed feedback selector (Pr 03.026), and the ELPR set for the position

feedback device. In RFC-A mode it is possible to disable this limit via

Pr 03.024, so that the drive can be switched between operation with and

without feedback when the speed becomes too high for the feedback

device. The maximum speed limit is defined as above when Pr 03.024 =

0 and is 36,000 rpm when Pr 03.024 = 1,2, 3 or 4.

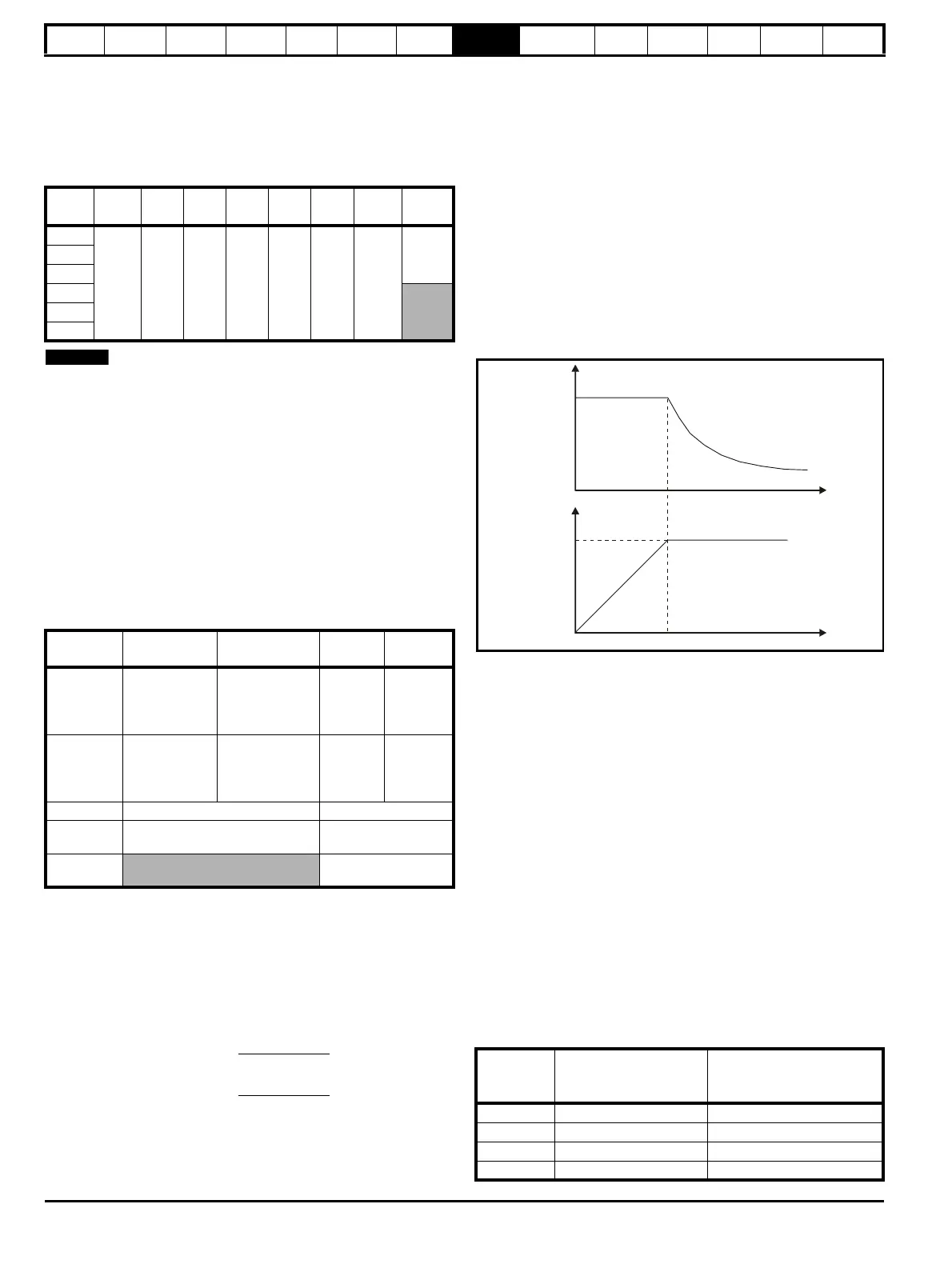

8.6.2 Field weakening (constant power) operation

(Open loop and RFC-A mode only)

The drive can be used to run an induction machine above synchronous

speed into the constant power region. The speed continues to increase

and the available shaft torque reduces. The characteristics below show

the torque and output voltage characteristics as the speed is increased

above the rated value.

Figure 8-3 Torque and rated voltage against speed

Care must be taken to ensure the torque available above base speed is

sufficient for the application to run satisfactorily.

The saturation breakpoint parameters (Pr 05.029, Pr 05. 030, Pr 05.062

and Pr 05.063) found during the autotune in RFC-A mode ensure the

magnetizing current is reduced in the correct proportion for the specific

motor. (In open loop mode the magnetizing current is not actively

controlled).

8.6.3 Permanent magnet motor high speed operation

High speed servo mode is enabled by setting Pr 05.022 =1. Care must

be taken when using this mode with permanent magnet motor to avoid

damaging the drive. The voltage produced by the permanent magnet

motor magnets is proportional to speed. For high speed operation the

drive must apply currents to the motor to counter-act the flux produced

by the magnets. It is possible to operate the motor at very high speeds

that would give a very high motor terminal voltage, but this voltage is

prevented by the action of the drive.

If however, the drive is disabled (or tripped) when the motor voltages

would be higher than the rating of the drive without the currents to

counter-act the flux from the magnets, it is possible to damage the drive.

If high speed mode is enabled the motor speed must be limited to the

levels given in the table below unless an additional hardware protection

system is used to limit the voltages applied to the drive output terminals

to a safe level.

Drive

size

Model

2

kHz

3

kHz

4

kHz

6

kHz

8

kHz

12

kHz

16

kHz

3

All

4

5*

6

7

8

Level

3, 6, 12

kHz

2, 4, 8, 16

kHz

Open

loop

RFC-A

RFC-S

Level 1

3 kHz - 167μs

6 kHz - 83 μs

12 kHz - 83 μs

2 kHz - 250 μs

4 kHz - 125 μs

8 kHz - 62.5 μs

16 kHz - 62.5 μs

Peak limit

Current

controllers

Level 2 250 μs

2 kHz - 500

μs

4 kHz - 250 μs

8 kHz - 250 μs

16 kHz - 250 μs

Current

limit and

ramps

Speed

controller

and ramps

Level 3 1 ms Voltage controller

Level 4 4 ms

Time critical user

interface

Background

Non-time critical user

interface

Maximum speed limit (rpm) =

500 kHz x 60

ELPR

=

3.0 x 10

7

ELPR

Drive

voltage

rating

Maximum motor speed

(rpm)

Maximum safe line to line

voltage at the motor

terminals (V rms)

200 400 x 1000 / (Ke x √2) 400 / √2

400 800 x 1000 / (Ke x √2) 800 / √2

575 955 x 1000 / (Ke x √2) 955 / √2

690 1145 x 1000 / (Ke x √2) 1145 / √2

Rated

voltage

Torq ue

Speed

Speed

Rated speed

Loading...

Loading...