Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running

the motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL listing

information

Unidrive M702 User Guide 65

Issue Number: 3

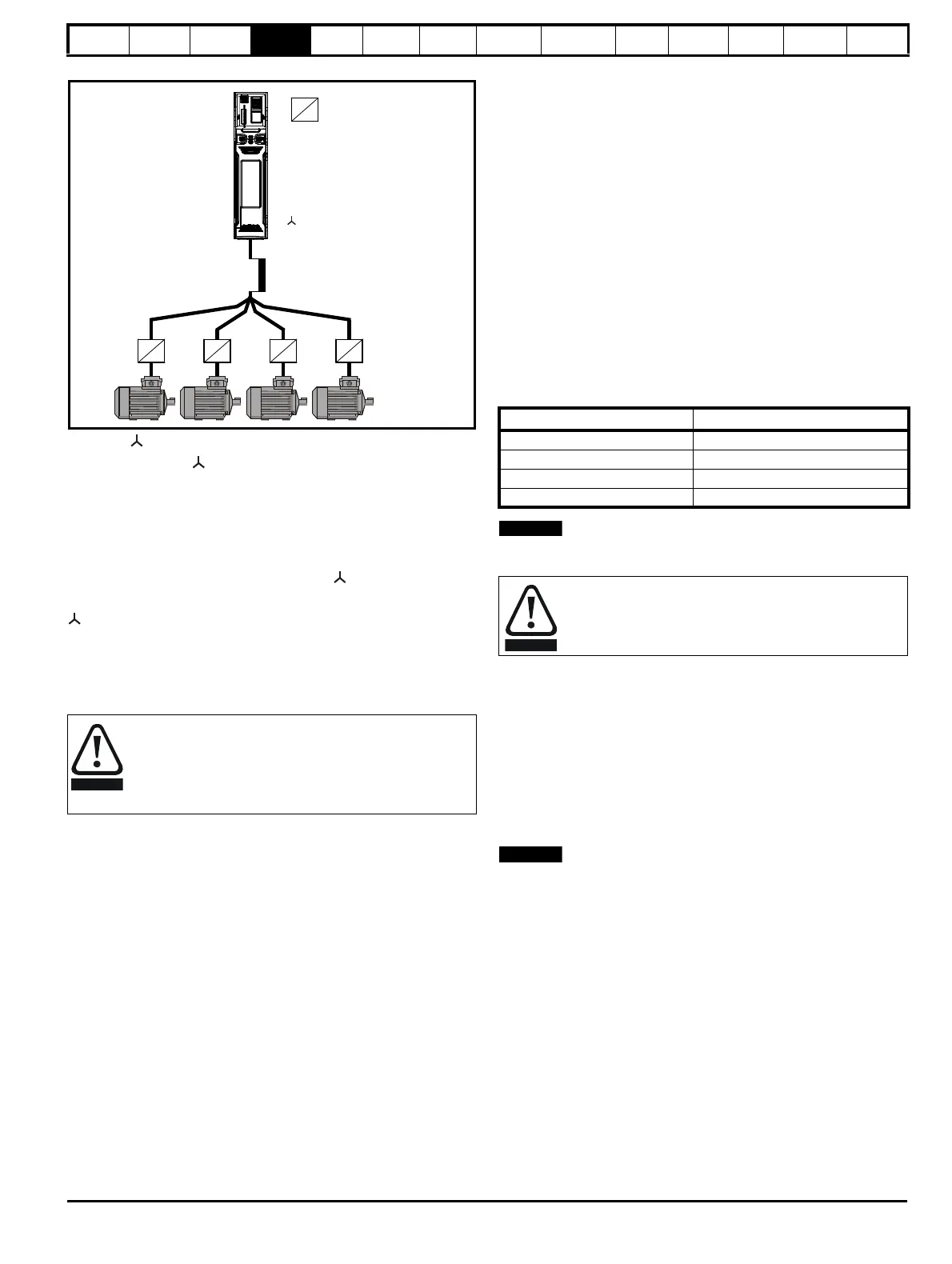

Figure 4-17 Alternative connection for multiple motors

4.9.5 / Δ motor operation

The voltage rating for

and Δ connections of the motor should always

be checked before attempting to run the motor.

The default setting of the motor rated voltage parameter is the same as

the drive rated voltage, i.e.

400 V drive 400 V rated voltage

230 V drive 230 V rated voltage

A typical 3 phase motor would be connected in

for 400 V operation or

Δ for 230 V operation, however, variations on this are common e.g.

690 V

Δ 400 V.

Incorrect connection of the windings will cause severe under or over

fluxing of the motor, leading to a very poor output torque or motor

saturation and overheating respectively.

4.9.6 Output contactor

A contactor is sometimes required to be installed between the drive and

motor for safety purposes.

The recommended motor contactor is the AC3 type.

Switching of an output contactor should only occur when the output of

the drive is disabled.

Opening or closing of the contactor with the drive enabled will lead to:

1. OI ac trips (which cannot be reset for 10 seconds)

2. High levels of radio frequency noise emission

3. Increased contactor wear and tear

The Drive Enable terminal (terminal 11 and terminal 13) when opened

provides a SAFE TORQUE OFF function. This can in many cases

replace output contactors.

For further information see section 4.16 SAFE TORQUE OFF (STO) on

page 86.

4.10 Braking

Braking occurs when the drive is decelerating the motor, or is preventing

the motor from gaining speed due to mechanical influences. During

braking, energy is returned to the drive from the motor.

When motor braking is applied by the drive, the maximum regenerated

power that the drive can absorb is equal to the power dissipation

(losses) of the drive.

When the regenerated power is likely to exceed these losses, the DC

bus voltage of the drive increases. Under default conditions, the drive

brakes the motor under PI control, which extends the deceleration time

as necessary in order to prevent the DC bus voltage from rising above a

user defined set-point.

If the drive is expected to rapidly decelerate a load, or to hold back an

overhauling load, a braking resistor must be installed.

Table 4-17 shows the default DC voltage level at which the drive turns on

the braking transistor. However the braking resistor turn on and the turn

off voltages are programmable with Braking IGBT Lower Threshold

(06.073) and Braking IGBT Upper Threshold (06.074).

Table 4-17 Default braking transistor turn on voltage

N

When a braking resistor is used, Pr 00.015 should be set to Fast ramp

mode.

4.10.1 Heatsink mounted braking resistor

A resistor has been especially designed to be mounted within the

heatsink of the drive (size 3, 4 and 5). See section 3.10 Heatsink

mounted brake resistor on page 43 for mounting details. The design of

the resistor is such that no thermal protection circuit is required, as the

device will fail safely under fault conditions. On size 3, 4 and 5 the in built

software overload protection is set-up at default for the designated

heatsink mounted resistor. The heatsink mounted resistor is not supplied

with the drive and can be purchased separately.

Table 4-18 provides the resistor data for each drive rating.

N

The internal / heatsink mounted resistor is suitable for applications with a

low level of regen energy only. See Table 4-18.

If the cable between the drive and the motor is to be

interrupted by a contactor or circuit breaker, ensure that the

drive is disabled before the contactor or circuit breaker is

opened or closed. Severe arcing may occur if this circuit is

interrupted with the motor running at high current and low

speed.

connection

Inductor

Motor protection

relay

Drive voltage rating DC bus voltage level

200 V 390 V

400 V 780 V

575 V 930 V

690 V 1120 V

High temperatures

Braking resistors can reach high temperatures. Locate

braking resistors so that damage cannot result. Use cable

having insulation capable of withstanding high temperatures.

Loading...

Loading...