Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running

the motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL listing

information

56 Unidrive M702 User Guide

Issue Number: 3

4.2.2 Supplies requiring line reactors

Input line reactors reduce the risk of damage to the drive resulting from

poor phase balance or severe disturbances on the supply network.

Where line reactors are to be used, reactance values of approximately 2

% are recommended. Higher values may be used if necessary, but may

result in a loss of drive output (reduced torque at high speed) because of

the voltage drop.

For all drive ratings, 2 % line reactors permit drives to be used with a

supply unbalance of up to 3.5 % negative phase sequence (equivalent to

5% voltage imbalance between phases).

Severe disturbances may be caused by the following factors, for example:

• Power factor correction equipment connected close to the drive.

• Large DC drives having no or inadequate line reactors connected to

the supply.

• Across the line (DOL) started motor(s) connected to the supply such

that when any of these motors are started, the voltage dip exceeds

20 %.

Such disturbances may cause excessive peak currents to flow in the

input power circuit of the drive. This may cause nuisance tripping, or in

extreme cases, failure of the drive.

Drives of low power rating may also be susceptible to disturbance when

connected to supplies with a high rated capacity.

Line reactors are particularly recommended for use with the following

drive models when one of the above factors exists, or when the supply

capacity exceeds 175 kVA:

03200050, 03200066, 03200080, 03200106,

03400025, 03400031, 03400045, 03400062

Model sizes 03400078 to 07600540 have an internal DC choke and

082001160 to 08600860 have internal AC line chokes so they do not

require AC line reactors except for cases of excessive phase unbalance

or extreme supply conditions.

When required, each drive must have its own reactor(s). Three individual

reactors or a single three-phase reactor should be used.

Reactor current ratings

The current rating of the line reactors should be as follows:

Continuous current rating:

Not less than the continuous input current rating of the drive

Repetitive peak current rating:

Not less than twice the continuous input current rating of the drive

4.2.3 Input inductor calculation

To calculate the inductance required (at Y%), use the following equation:

Where:

I = drive rated input current (A)

L = inductance (H)

f = supply frequency (Hz)

V = voltage between lines

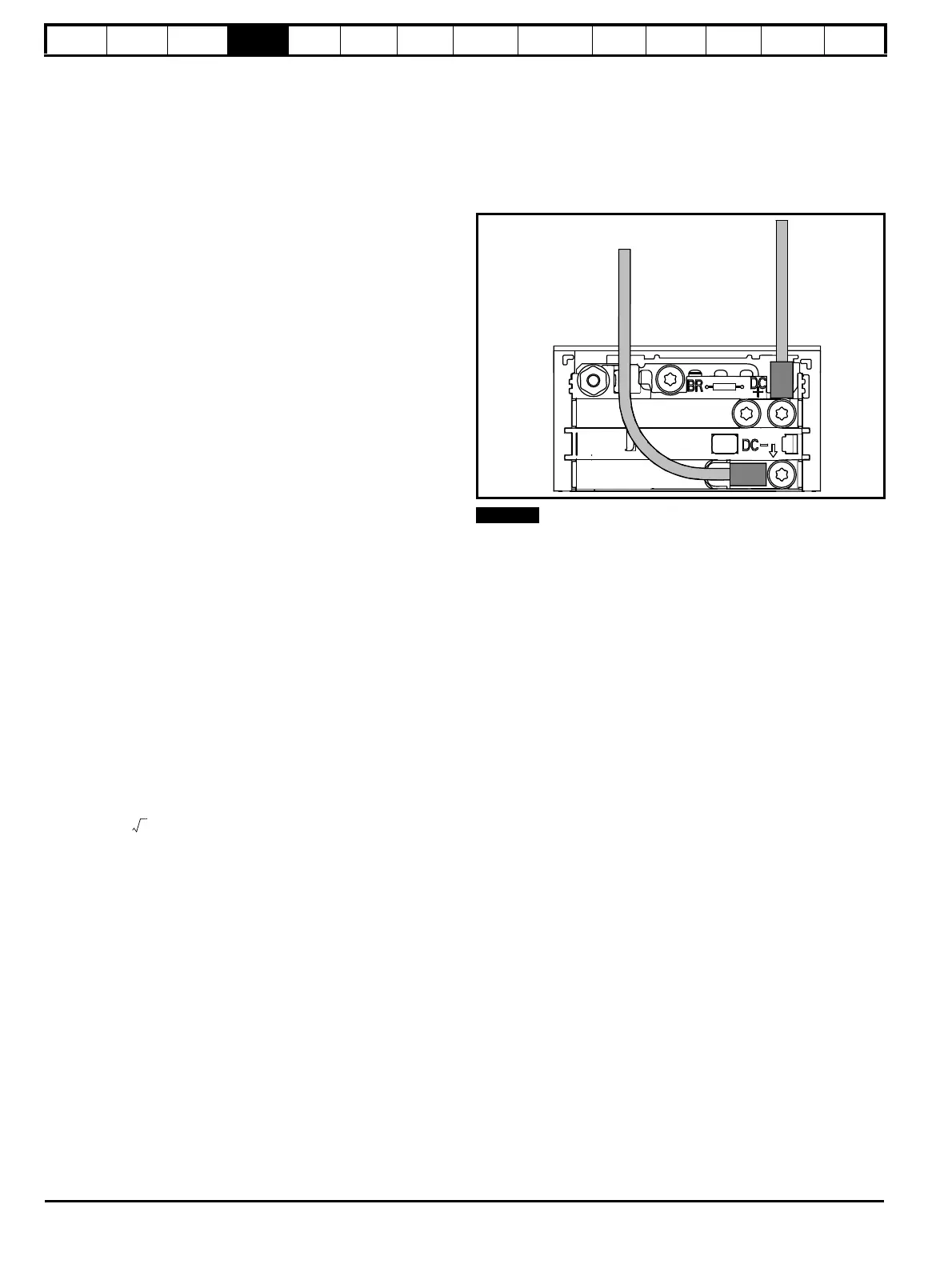

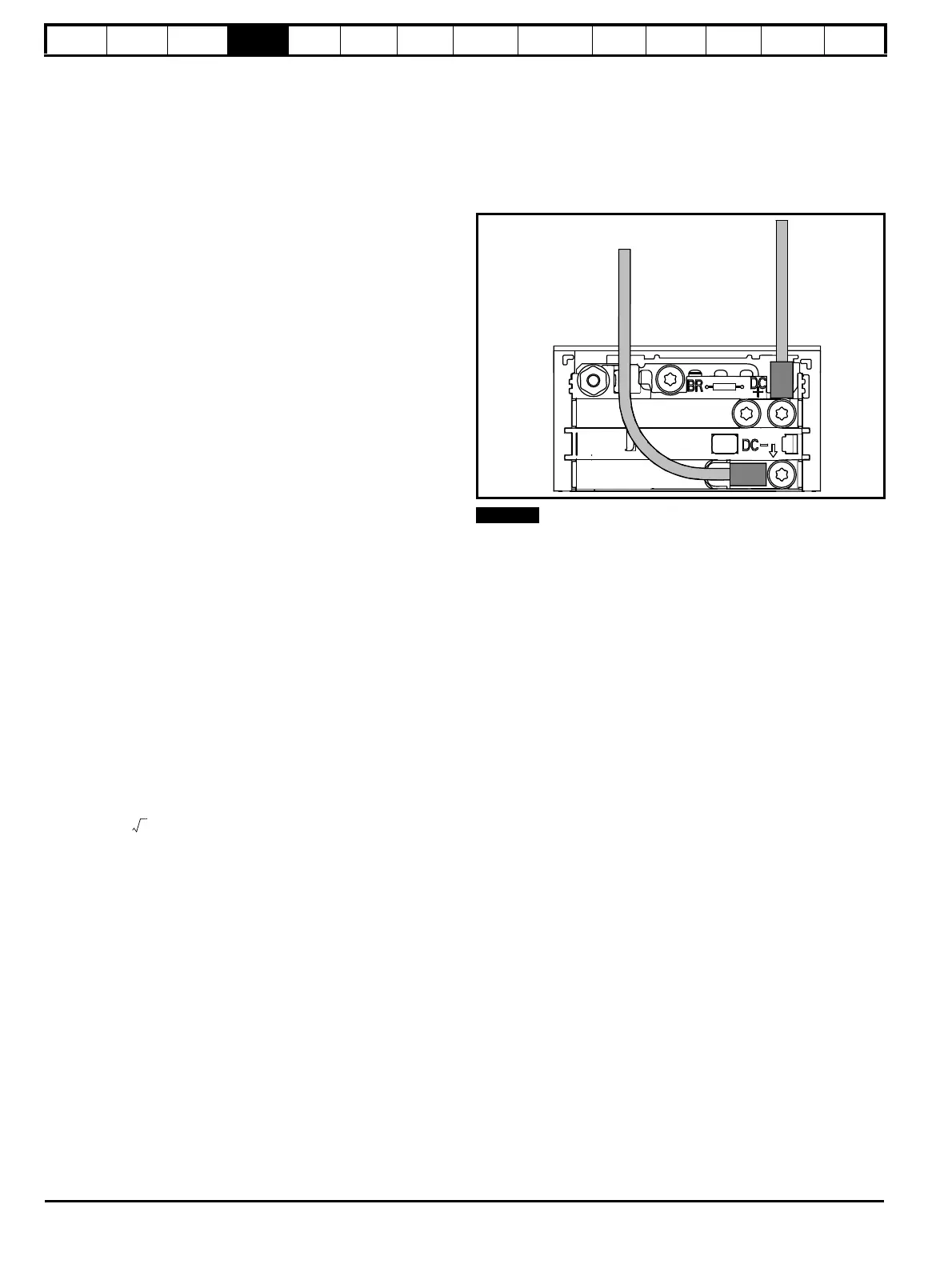

4.3 Supplying the drive with DC

All drive sizes have the option to be powered from an external DC power

supply. Refer to section 3.12 Electrical terminals on page 47 to identify

the location of DC supply connections.

The DC supply connections for size 3 are located under the DC / Braking

terminal cover. Figure 4-10 shows DC supply connections and cable

routing.

Figure 4-10 DC supply connections (size 3 shown)

The Internal EMC filter and plastics have been removed from the above

Figure 4-10 to demonstrate the routing of the DC cables.

L

Y

100

----------

V

3

-------

×

1

2πfI

------------

×=

Loading...

Loading...