Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running

the motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL listing

information

40 Unidrive M702 User Guide

Issue Number: 3

Example

To calculate the size of an enclosure for the following:

• Three drives operating at the Normal Duty rating

• External EMC filter for each drive

• Braking resistors are to be mounted outside the enclosure

• Maximum ambient temperature inside the enclosure: 40 °C

• Maximum ambient temperature outside the enclosure: 30 °C

For example, dissipation of each drive: 101 W and dissipation of each

external EMC filter: 6.9 W (max).

Total dissipation: 3 x (101 + 6.9) = 323.7 W

Insert the following values:

T

int

40 °C

T

ext

30 °C

k 1.3

P 323.7 W

Then:

= 126.2 m

3

/hr (74.5 ft

3

/min) (1 m

3

/ hr = 0.59 ft

3

/min)

3.7 Enclosure design and drive ambient

temperature

Drive derating is required for operation in high ambient temperatures

Totally enclosing or through panel mounting the drive in either a sealed

cabinet (no airflow) or in a well ventilated cabinet makes a significant

difference on drive cooling.

The chosen method affects the ambient temperature value (T

rate

) which

should be used for any necessary derating to ensure sufficient cooling

for the whole of the drive.

The ambient temperature for the four different combinations is defined

below:

1. Totally enclosed with no air flow (<2 m/s) over the drive

T

rate

= T

int

+ 5 °C

2. Totally enclosed with air flow (>2 m/s) over the drive

T

rate

= T

int

3. Through panel mounted with no airflow (<2 m/s) over the drive

T

rate

= the greater of T

ext

+5 °C, or T

int

4. Through panel mounted with air flow (>2 m/s) over the drive

T

rate

= the greater of T

ext

or T

int

Where:

T

ext

= Temperature outside the cabinet

T

int

= Temperature inside the cabinet

T

rate

= Temperature used to select current rating from tables in

Chapter 12 Technical data on page 227.

3.8 Heatsink fan operation

The drive is ventilated by an internal heatsink mounted fan. The fan

housing forms a baffle plate, channelling the air through the heatsink

chamber. Thus, regardless of mounting method (surface mounting or

through-panel mounting), the installing of additional baffle plates is not

required.

Ensure the minimum clearances around the drive are maintained to

allow air to flow freely.

The heatsink fan on all sizes is a variable speed fan. The drive controls

the speed at which the fan runs based on the temperature of the

heatsink and the drive's thermal model system. The maximum speed at

which the fan operates can be limited in Pr 06.045. This could incur an

output current derating. Refer to section 3.13.2 Fan removal

procedure on page 50 for information on fan removal. The size 6

onwards is also installed with a variable speed fan to ventilate the

capacitor bank.

3.9 Enclosing standard drive for high

environmental protection

An explanation of environmental protection rating is provided in section

12.1.9 IP / UL Rating .

The standard drive is rated to IP20 pollution degree 2 (dry, non-

conductive contamination only) (NEMA 1). However, it is possible to

configure the drive to achieve IP65 rating (NEMA 12) at the rear of the

heatsink for through-panel mounting (some current derating is required).

Refer to Table 12-2 on page 229.

This allows the front of the drive, along with various switchgear, to be

housed in an IP65 (NEMA 12) enclosure with the heatsink protruding

through the panel to the external environment. Thus, the majority of the

heat generated by the drive is dissipated outside the enclosure

maintaining a reduced temperature inside the enclosure. This also relies

on a good seal being made between the heatsink and the rear of the

enclosure using the gaskets provided.

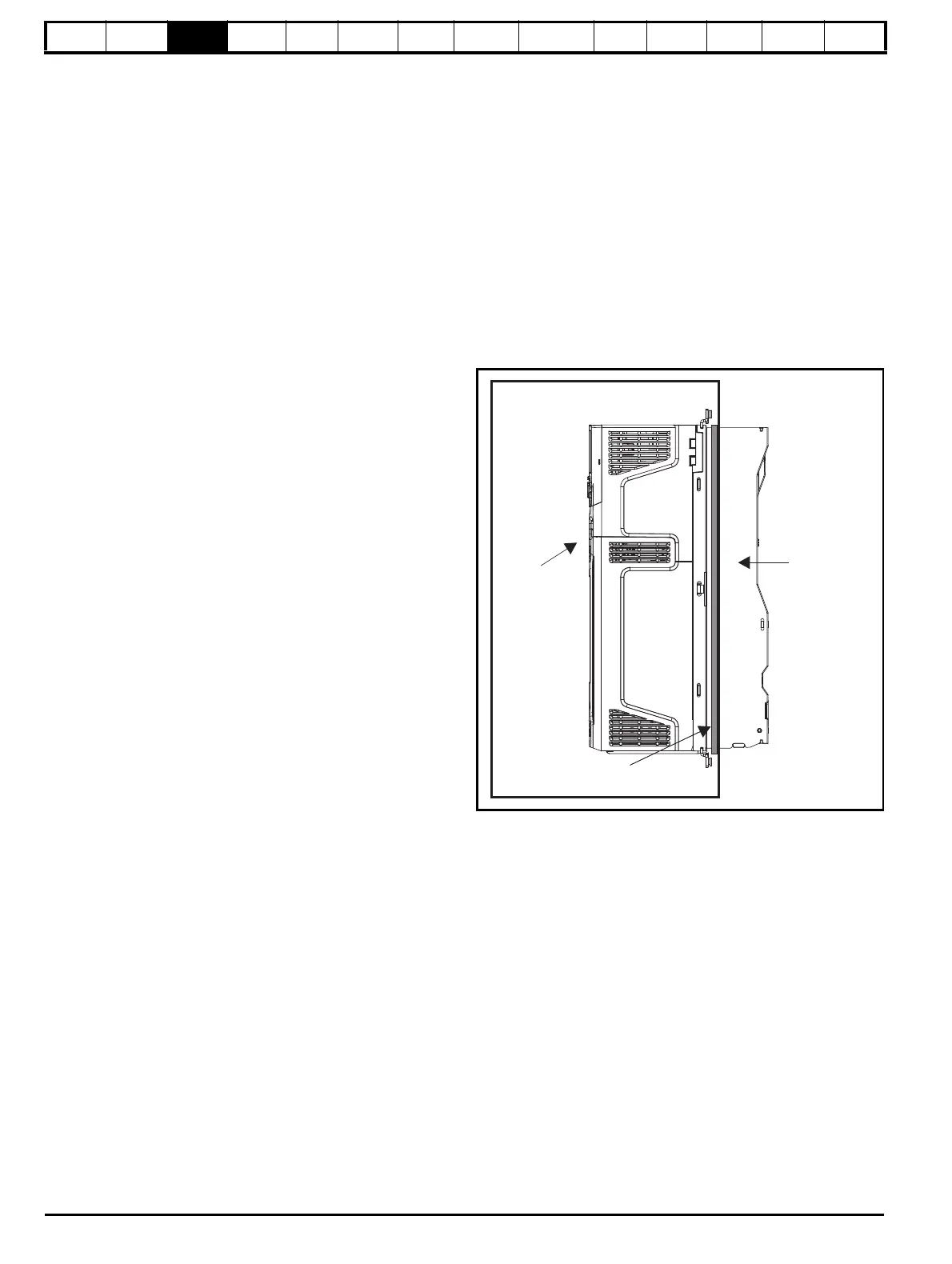

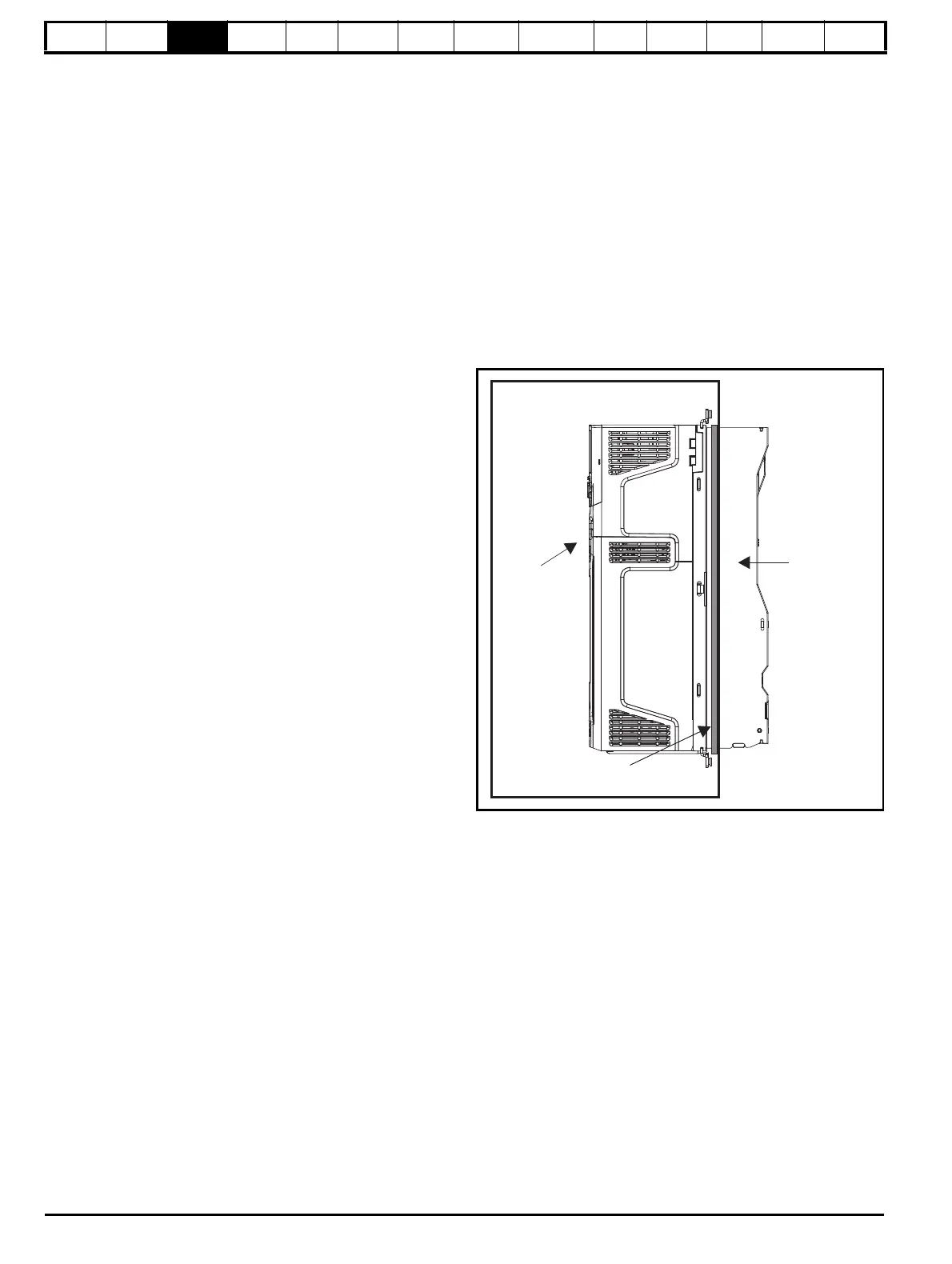

Figure 3-30 Example of IP65 (NEMA 12) through-panel layout

The main gasket should be installed as shown in Figure 3-31.

On drive sizes 3, 4 and 5, in order to achieve the high IP rating at the

rear of the heatsink it is necessary to seal a heatsink vent by installing

the high IP insert as shown in Figure 3-33, Figure 3-34 and Figure 3-35.

V

31.3× 323.7×

40 30–

---------------------------------------

=

IP20

(NEMA1)

IP65 (NEMA 12)

enclosure

Drive with

high IP insert

installed

Gasket

seal

Loading...

Loading...