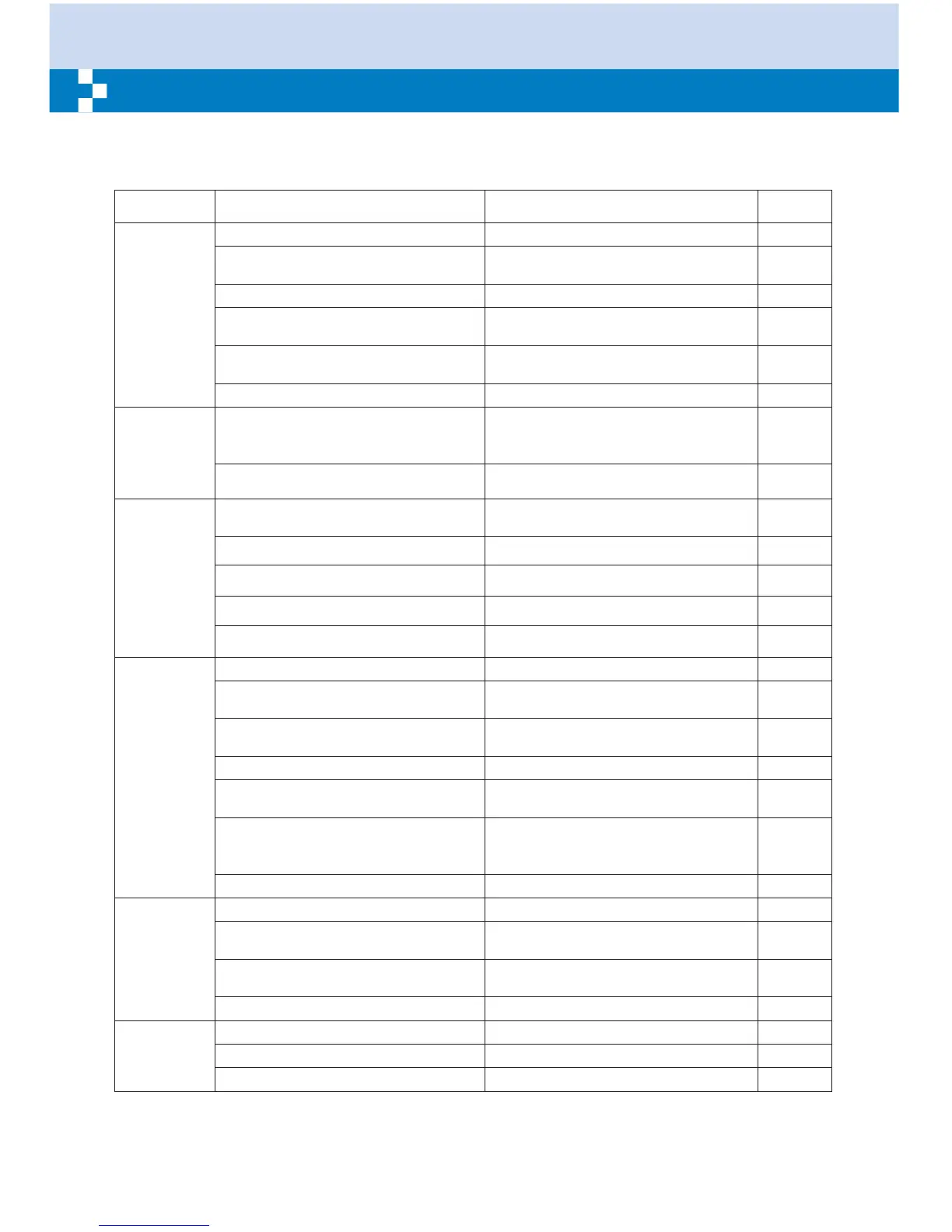

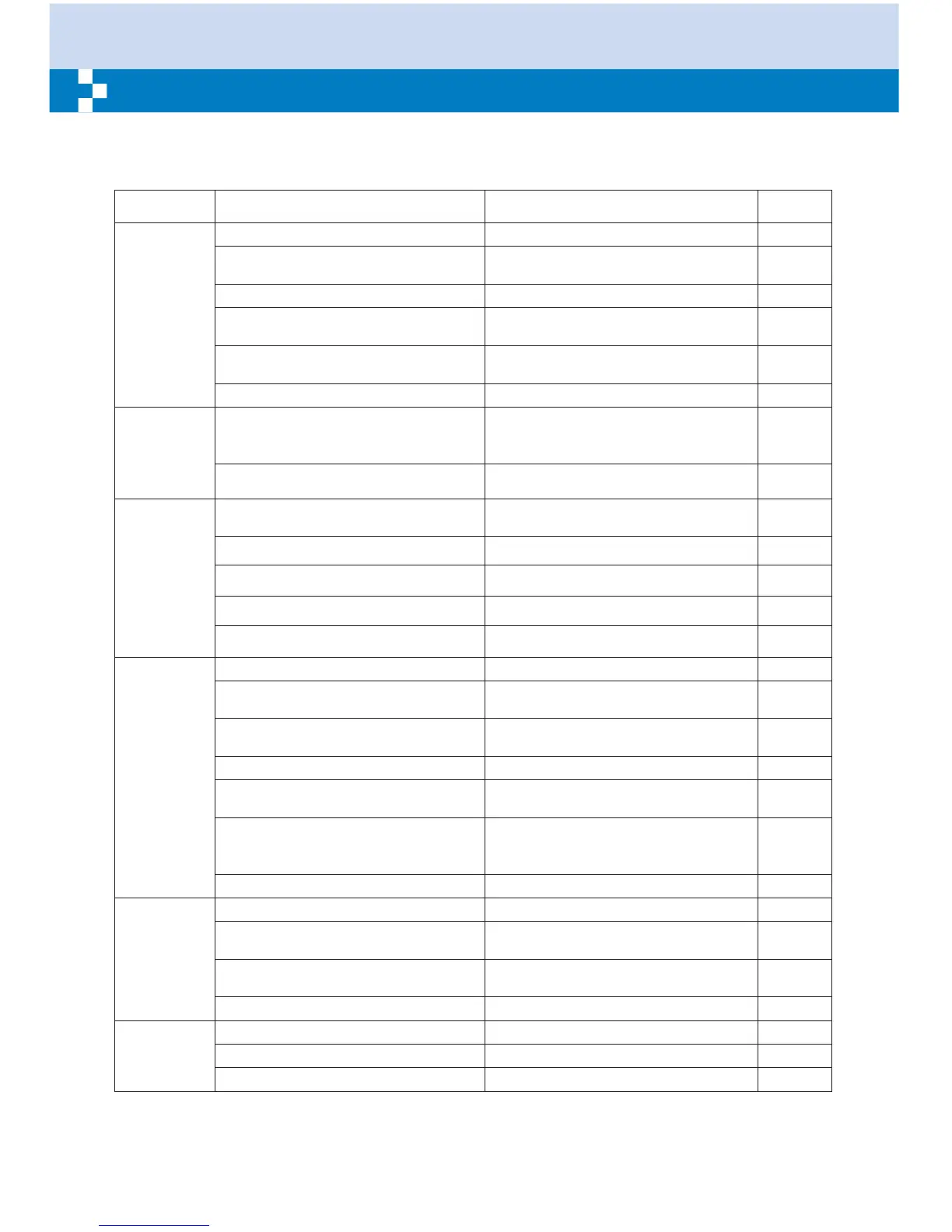

Before calling for service, check the following items. If the problem still persists, contact the place

of purchase or your nearest authorized dealer.

1.The machine is not threaded correctly.

2.The thread tension is too tight.

2.Reduce the thread tension (lower

number).

3.The thread is too thick for the needle.

3.Select a larger needle.

4.The needle is not inserted correctly.

4.Remove and reinsert the needle (flat

side towards the back).

5.The thread is wound around the spool

holder pin.

5.Remove the reel and wind thread onto

reel.

1.The bobbin case is not inserted

correctly.

1.Remove and reinsert the bobbin case

and pull on the thread. The thread

should pull easily.

2.The bobbin case is threaded wrong.

2.Check both bobbin and bobbin case.

1.The needle is not inserted correctly.

1.Remove and reinsert needle(flat side

towards the back).

3.The wrong size needle has been used.

3.Choose a needle to suit the thread.

4.The foot is not attached correctly.

4.Check and attach correctly.

5.The machine is not threaded correctly.

2.The needle is not correctly inserted.

2.Insert the needle correctly (flat side

towards the back).

3.Wrong needle size for the fabric.

3.Choose a needle to suit the thread and

fabric.

4.The wrong foot is attached.

4.Select the correct foot.

5.The needle clamp screw is loose.

5.Use the screwdriver to firmly tighten

the screw.

6.The presser foot that is used is not

appropriate for the type of stitch that

you wish to sew.

6.Attach the presser foot that is appro-

priate for the type of stitch that you

wish to sew.

7.The upper thread tension is too tight.

7.Loosen the upper thread tension.

1.The machine is not correctly threaded.

2.The bobbin case is not correctly

threaded.

2.Thread the bobbin case as illustrated.

3.Needle/fabric/thread combination is

wrong.

3.The needle size must suit the fabric

and thread.

4.Thread tension is wrong.

4.Correct the thread tension.

1.The needle is too thick for the fabric.

2.The stitch length is adjusted wrong.

2.Readjust the stitch length.

3.The thread tension is too tight.

3.Loosen the thread tension.

Loading...

Loading...