Operation Liquiline System CA80SI

72 Endress+Hauser

11.4.1 Application examples

Chlorine regulation with feedforward control

CCA250

CA80

Flow, e.g. Promag53

A

BU

BK

BN

CCA250

INS

47

48

91

92

CA80

DIO

1

2

3

Dig.in

CA80: DIO

Dig.in: PFM

91

92

+

–

45

46

CA80

DIO

Dig.out: PFM

A0029239

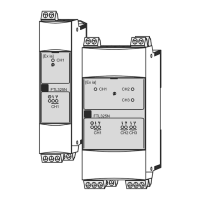

63 Example of chlorine control with feedforward control

1 Connection of the inductive proximity switch INS of CCA250 to the digital input of the DIO module

2 Connection of the signal from a flowmeter to the digital input of the DIO module

3 Activation of a (pulse) dosing pump via the digital output of the DIO module

A Dosing pump

Utilize the advantage of the effectively wear-free control with binary outputs versus a

control system with relay. With pulse frequency modulation (PFM), it is possible to achieve

virtually continuous dosing using a dosing pump with higher input frequency.

1. Connect the INS proximity switch of the CCA250 assembly to a digital input of the

DIO module (e.g. slot 6, port 1).

2. In the software, configure a controller and as the source select the binary input

(e.g.Binary input 1) to which the proximity switch is connected. (Menu/Additional

functions/Controllers/Controller 1/Controller Enable = Binary input 1)

3. Signal type: For the selected input, select the factory setting (Static signal).

4. Connect the measured value of a flowmeter to the second input of the DIO module

(e.g. slot 6, port 2).

5. Signal type: for this input, select PFM . (Menu/Inputs/Binary input 6:2/Signal

type = PFM)

6. Input mode: select the corresponding measured value (Flow rate).

You can now use the input you have just configured as the disturbance variable

for your controller

1)

.

1) An activation code, Order No. 71211288, is necessary for the "feedforward control" function.

Loading...

Loading...