Machine description – quick overview

Machine control – Operating elements

099-000115-EW501

17.06.2015

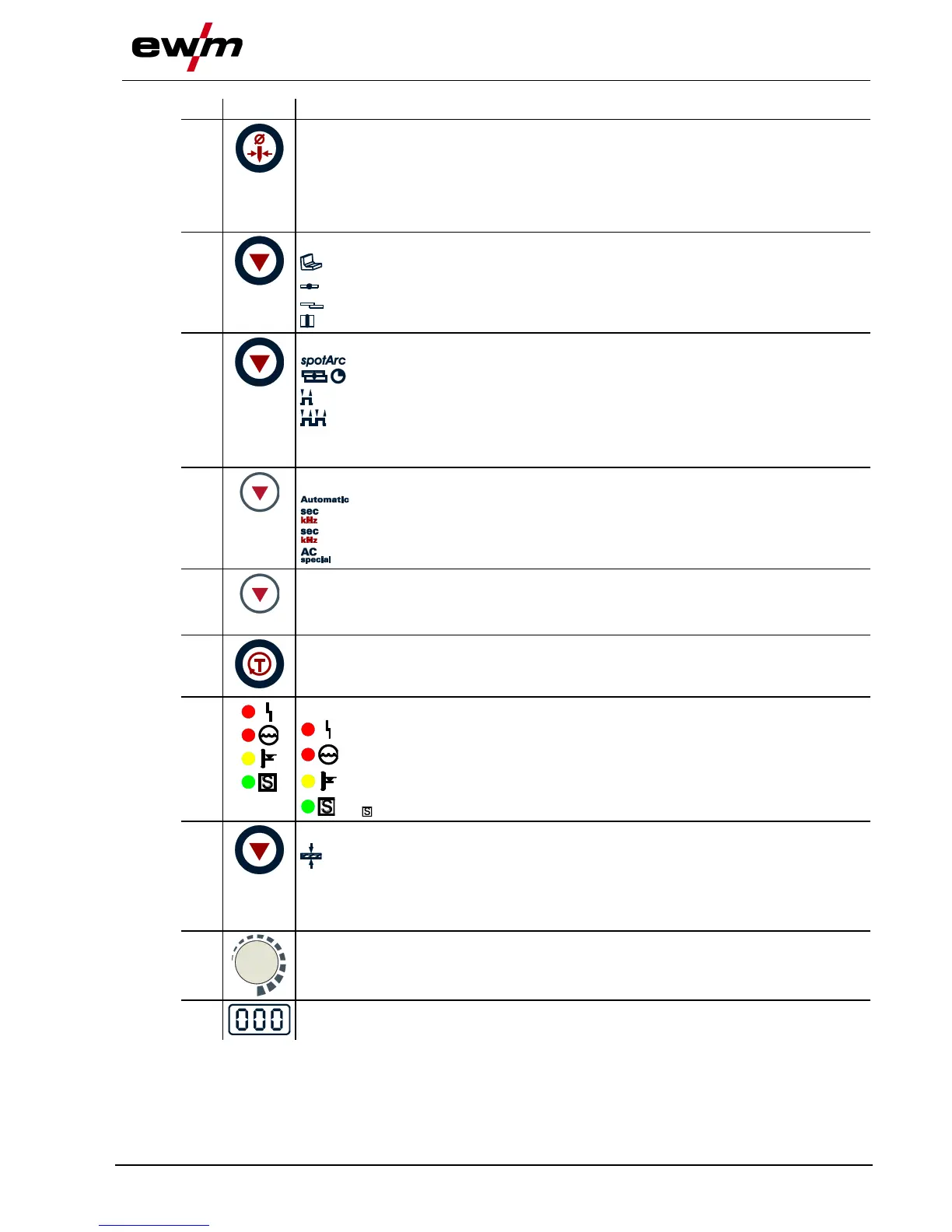

Tungsten electrode diameter / Ignition optimisation / Spherical cap formation button

1.0mm, 1.6mm, 2.0mm, 2.4mm, 3.2mm, 4.0mm or greater

Best ignition and stabilisation of the arc (DC, AC) and optimum spherical cup formation

in the tungsten electrode according to the electrode diameter being used. The

adjustable welding current is limited to the maximum permissible welding current of the

tungsten electrode.

Select seam type button

Fillet weld

Butt joint

Fillet weld - lap joint

Vertical-down

Operating mode / Power-saving mode button

spotArc / Spotmatic (spot time setting range)

Non-latched

Latched

Press for 3 s to put machine into power-saving mode. To reactivate, activate one of the

operating elements- See 5.22.3 Power-saving mode (Standby) chapter.

Pulsing push-button

TIG automated pulsing (frequency and balance)

Signal light lights up in green: Pulsing (thermal pulsing)/MMA pulse welding

Signal light lights up in red: kHz pulsing (metallurgical pulsing)

Special TIG AC

Synchronisation types key button (two-sided, simultaneous welding)

Synchronisation via mains voltage

Synchronisation via cable

Gas test/rinse hose package button

- See 5.8.2 Setting the shielding gas quantity chapter

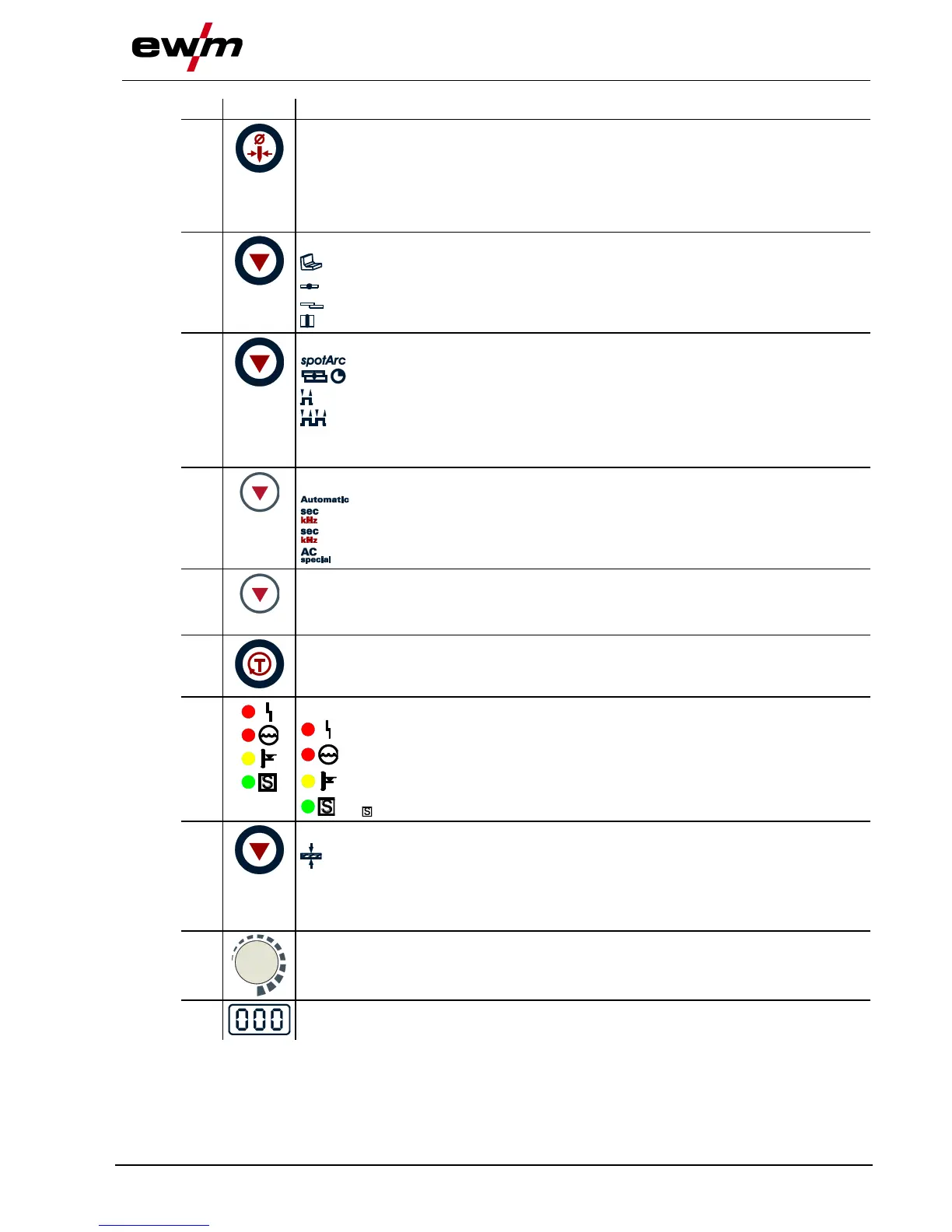

Error/status indicators

Collective interference signal light

Water deficiency signal light (welding torch cooling)

Excess temperature signal light

safety sign signal light

Display switching button

Material thickness display

VOLT Welding voltage display

JOB JOB number display

PROG Program number display

Welding parameter setting rotary transducer

Setting of all parameters such as welding current, sheet metal thickness, gas pre-flow

time, etc.

Welding data display (3-digit)

Displays the welding parameters and the corresponding values

Loading...

Loading...