Design and function

MMA welding

099-000115-EW501

17.06.2015

Select hotstart time welding parameter:

Press until the hotstart time signal light sec comes

on.

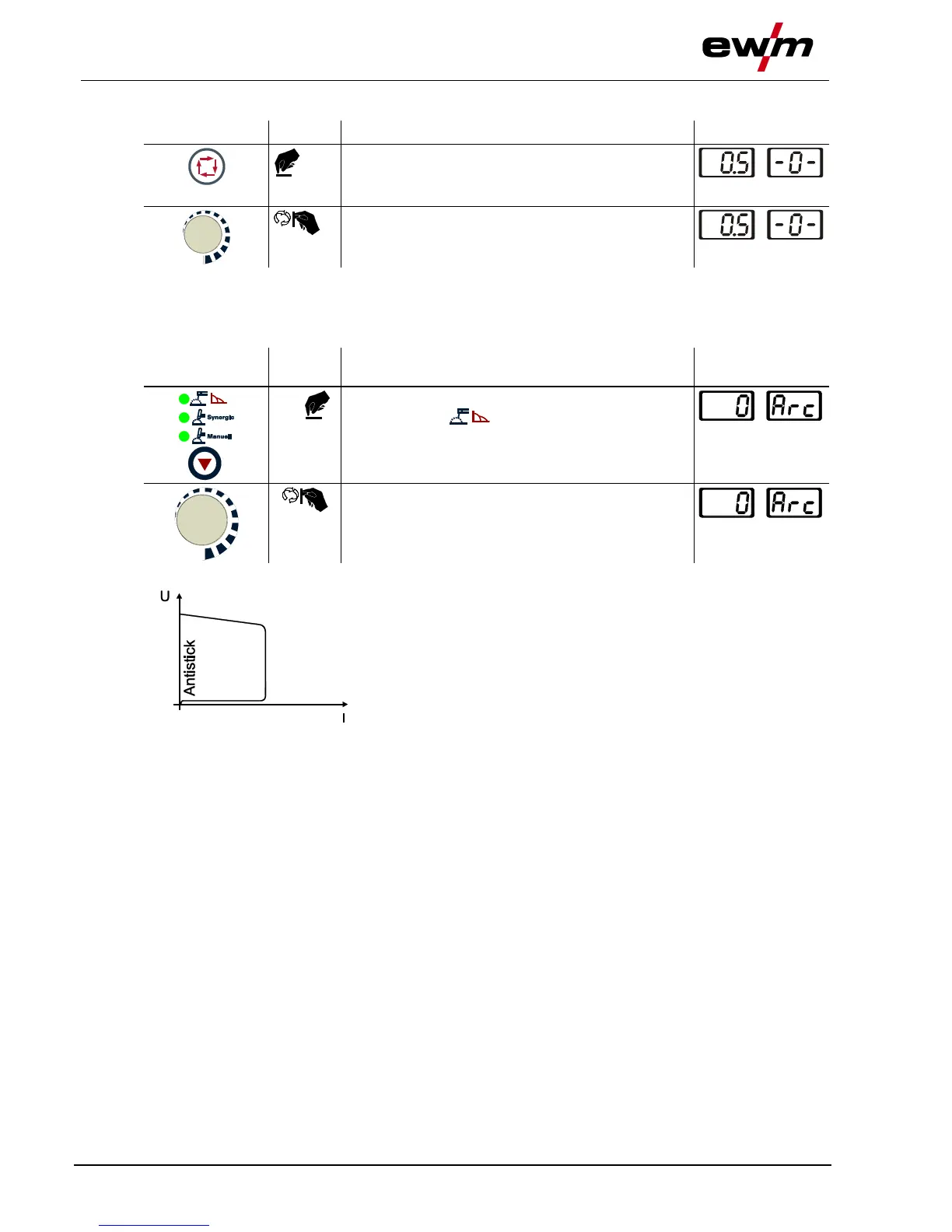

5.14.7 Arcforce

During the welding process, arcforce prevents the electrode sticking in the weld pool with increases in

current. This makes it easier to weld large-drop melting electrode types at low current strengths with a

short arc in particular.

Select arcforcing welding parameter.

The signal light comes on in red.

Set arcforcing.

-40 = rutile electrode types

0 = basic electrode types

+40 = cellulose electrode types

Anti-stick prevents the electrode from annealing.

If the electrode sticks in spite of the Arcforce device, the machine

automatically switches over to the minimum current within about 1

second to prevent the electrode from overheating. Check the welding

current setting and correct according to the welding task!

Loading...

Loading...