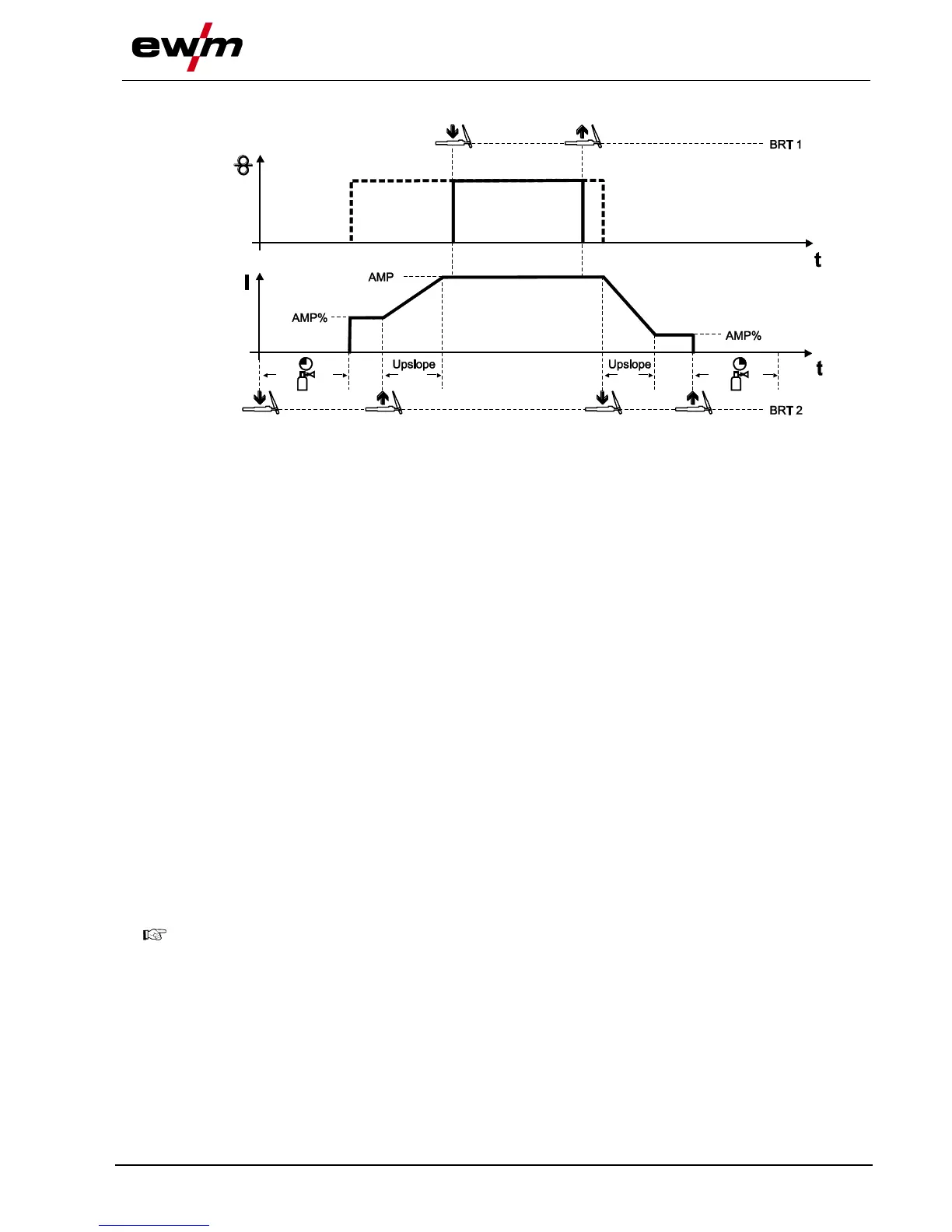

5.11.4.2 Non-latched mode

Figure 5-16

1st cycle (current)

• Press torch trigger 2 (BRT 2), the gas pre-flow time elapses.

• HF ignition pulses jump from the tungsten electrode to the workpiece. The arc ignites.

• Welding current flows and immediately assumes the set ignition current AMP%

(search arc at minimum setting). HF switches off.

2nd cycle (current)

• Release BRT 2.

• The welding current ramps up to the main current AMP in the selected up-slope time.

1st cycle (wire)

• Press torch trigger 1 (BRT 1).

Wire electrode is advanced.

2nd cycle (wire)

• Release BRT 1.

Wire electrode advance stops.

3rd cycle (current)

• Press BRT 2.

• The main current ramps down to the end-crater current I

end

(AMP%) in the selected down-slope time.

4th cycle (current)

• Release BRT 2. Arc extinguishes.

• Shielding gas continues to flow for the selected gas post-flow time.

Ending the welding process without down-slope time and end-crater current:

• Tap BRT 2 (tapping function).

Shielding gas continues to flow for the selected gas post-flow time.

Swiftly tap the torch trigger to change the function.

The torch mode set determines the operating mode of the tapping function.

Loading...

Loading...