Design and function

TIG Synergic operating principle

099-000115-EW501

17.06.2015

5.13.8 Optimising the ignition characteristics for pure tungsten electrodes

This parameter can be used to improve the ignition characteristics of “pure tungsten electrodes”, for

example. The parameter is a %-value (factory-set to 20) and is changed across all JOBs.

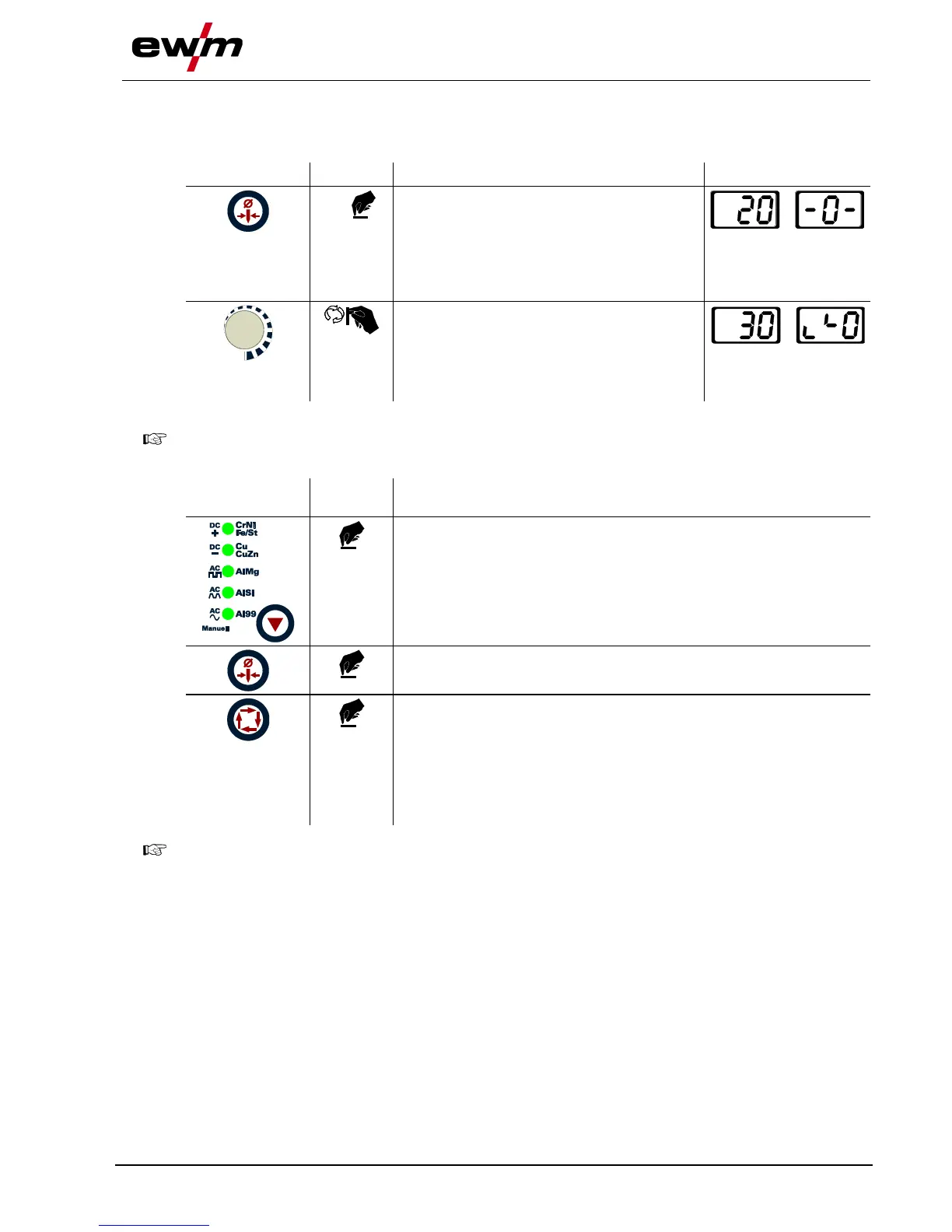

Select Ignition Characteristics parameter

The signal lights for the selected electrode

diameter and ignition current AMP% flash for

approx. 5 seconds. The parameter value can

be optimised on the rotary transducer during

this time.

Set parameter value

Increase parameter value:

more ignition power

Reduce parameter value:

less ignition power

5.13.9 Optimal and fast spherical cup formation

A conically ground tungsten electrode (approx. 35°) is generally required to form an ideal

spherical cup.

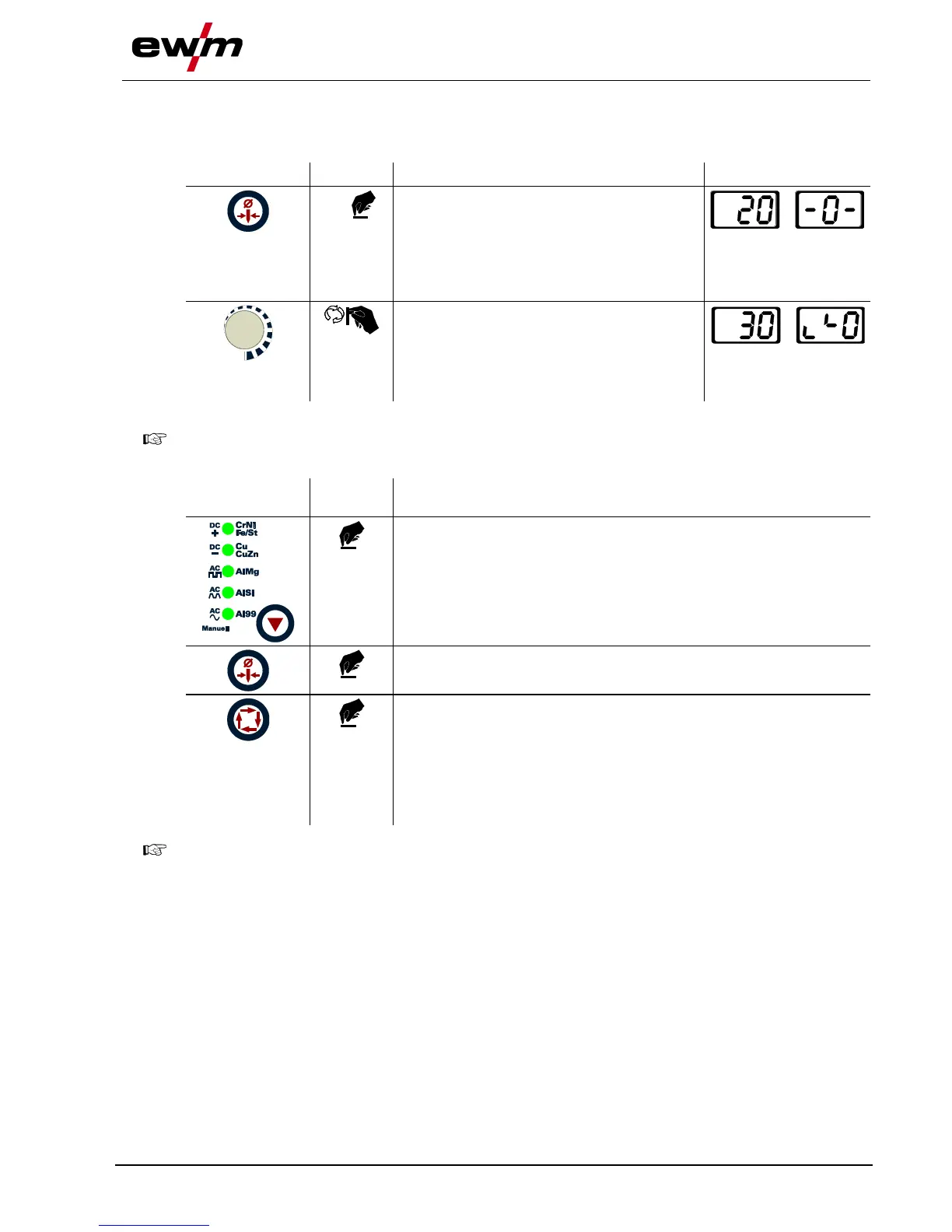

Select AC/DC welding with appropriate material:

AlMg aluminium and magnesium alloys.

AlSi aluminium and silicon alloys or

Al99 aluminium 99%

Ignition optimisation selection

The signal light of the selected needle diameter starts flashing.

Tungsten balling selection

The main current signal light flashes rapidly.

The current for tungsten balling is displayed and can be adjusted during

the process.

This function is switched off by pressing the ignition optimisation push-

button again or automatically after the set gas post-flow time has

elapsed.

• Use a sample workpiece.

• Ignite arc with HF ignition (non-contact) and form required spherical cup for the application in

question.

Loading...

Loading...