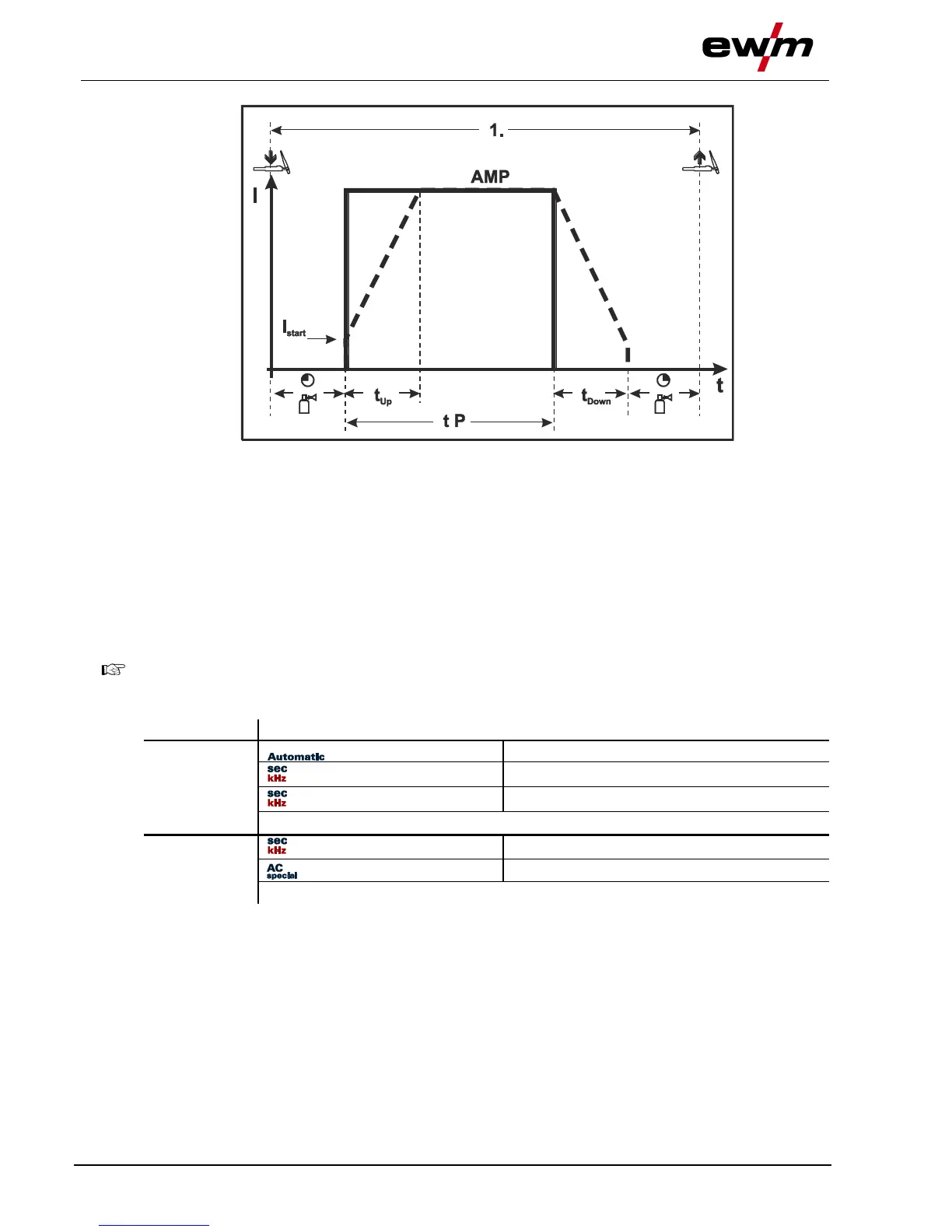

Figure 5-32

As an example the process is shown with HF ignition. Arc ignition with lift arc is also possible, however-

See 5.13.7 Arc ignition chapter.

Sequence:

• Press and hold torch trigger 1.

• The gas pre-flow time elapses.

• HF ignition pulses jump from the electrode to the workpiece, the arc ignites.

• The welding current flows and immediately assumes the value set for the ignition current I

start

.

• HF is switched off.

• The welding current increases in the adjusted up-slope time to the main current AMP.

Loading...

Loading...