FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

18

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

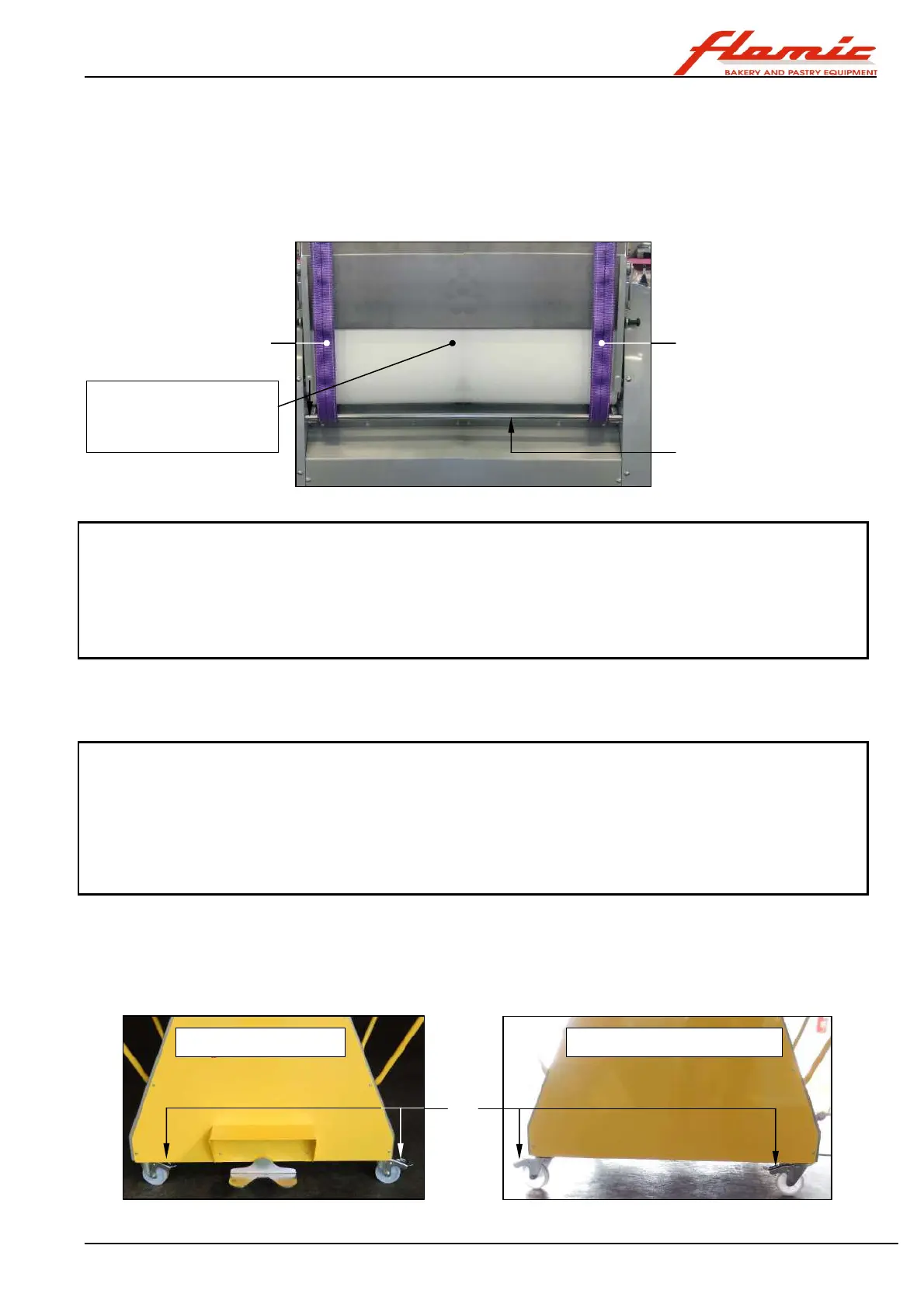

- models SF500, SF500B and SF600: insert the forks of the forklift truck from the side opposite the controls,

inside and as close to the points at which the base rests on the floor (wheels for SF500 and SF600, feet for

SF500B). The forks must protrude by at least 200 mm from the opposite side.

Model SF600 machines are shipped with the benches dismounted and packaged together with the rest of the

machine. The cutting unit, if ordered, will also be included in the same package (see Figure 8/A).

Models SF450 and SF500 are shipped with the benches installed and folded (Figure 8/B-C).

Accessories and optionals are usually packaged together with the machine.

Figure 9 - Lifting slings for model SF450

WARNING

Do not use handling devices and/or systems other than those described here.

The removal of packaging materials, handling and positioning should and must only be carried out by

skilled personnel (mechanical technicians, handling equipment operators trained to use forklift trucks) that are

wearing safety footwear with reinforced toecaps and a puncture-resistant sole (because of the possible

presence of nails), abrasion resistant work gloves and a hard hat.

When handling and/or transporting the machine or its parts, take all the necessary precautions to avoid

or to minimize risks to people, animals and property.

Only lift the machine as much as is strictly necessary, avoid jolting it and place it on the floor as soon as

possible. The machine is fitted with 4 wheels (except for version “B”) so once on the floor, it can be moved by

simply pushing it.

WARNING

When moving the machine on its wheels, the tables must be in the lowered position and, if for any

reason, they need to be raised (for example to save space during storage) it should be done only at the last

moment.

Moving the machine on its wheels with the benches in the upright position may pose a tipping over and

falling hazard (for example if it were to hit an obstacle on the floor or a wheel were to go into a hole in the floor)

and the impact could cause severe bruising to the exposed persons.

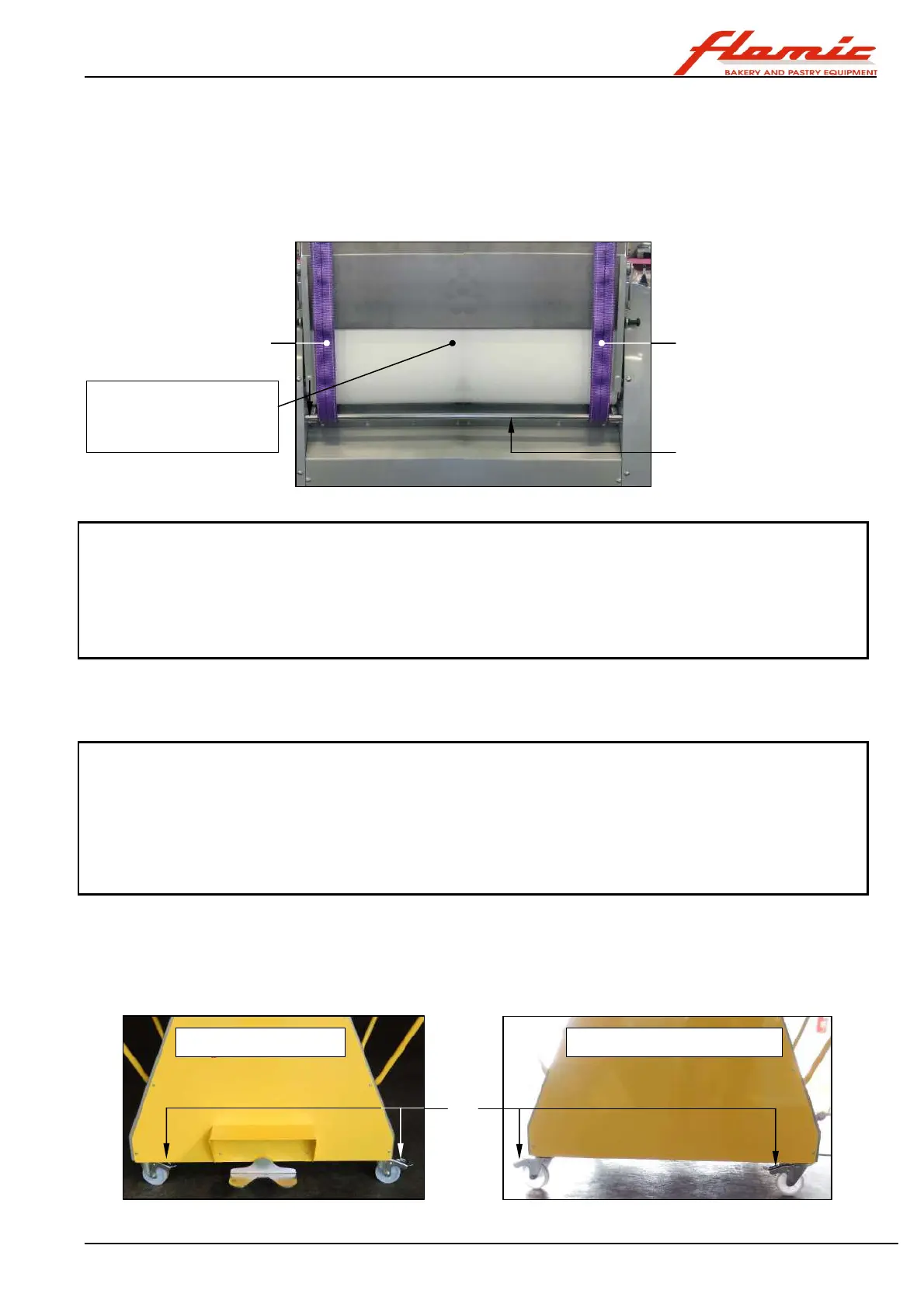

The same applies for model SF450 machines that are mounted and properly secured on the trolley (optional)

supplied by Flamic (see Figure 2).

When positioning the machine, leave adequate clearance around it, not only for work related to production, but

also for any other work that needs to be carried out, for example, cleaning. It is usually sufficient to leave 1000

mm of free space on each side, unless the machine is at the edge of an escape route, in which case at least

1200 mm of space should be left. All doors close to the machine must be unobstructed and easy to open. The

same applies to doors of furniture, appliances, machines etc. Before using the machine, lock the wheels (if

present) with the brake levers ref. 1 Figure 10

Figure 10 - Wheel brake levers

Side opposite the controls

1

1

1

2

Tables folded and

secured (see section

3.6.1)

Loading...

Loading...