FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

53

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

- remove the upper and lower scrapers (section 4.5). The scraper units can be washed separately in the same

way and with the same precautions described in the previous point for the cutting unit and rollers.

- wear safety footwear with reinforced toecaps, a dust mask (which has a filtering capacity that is

appropriate for the particle size of the flour. See section 3.11.1, part 8), safety eyewear with side shields

and waterproof gloves. Ventilate the room during and for at least 15 minutes after cleaning has been

completed. If possible, clean in an open or well-ventilated area.

- remove the under-table and central residue collection trays (section 3.8) and after removing any residues that

have been collected, clean it with a damp cloth moistened with clean water.

- using a vacuum cleaner fitted with a narrow nozzle, removed deposits of flour and residues of dough from all

parts of the machine. If necessary, remove the most stubborn residues using a plastic spatula and a brush

with medium-hard synthetic bristles. Before using the vacuum cleaner, and only when absolutely necessary,

use short blasts of compressed air to loosen residues from parts that are difficult to reach.

- using a brush with medium-hard synthetic bristles, remove or loosen any residues from the conveyor belts (if

necessary and taking the safety precautions indicated above, using short blasts of compressed air), then use

the vacuum cleaner to remove the residues.

- using damp cloths moistened with clean water, but not soaking, clean any surface that is in contact with or that

can come in contact with foodstuffs. In particular the rollers, interlocked guards and internal uprights

- again, using clean cloths moistened with clean water (but not soaking), clean the other surfaces, including

parts of the base under the conveyor belts, after having moved the latter into the upright position (section 3.6).

Lastly, dry the surfaces well using clean cloths. Be careful not to wet the control devices.

Do not use metal objects to avoid damaging the parts. Do not use water jets/spray water.

Make sure that the machine is completely dry before using it. If it is not, deposits and encrustations may form,

which in time may become difficult to remove.

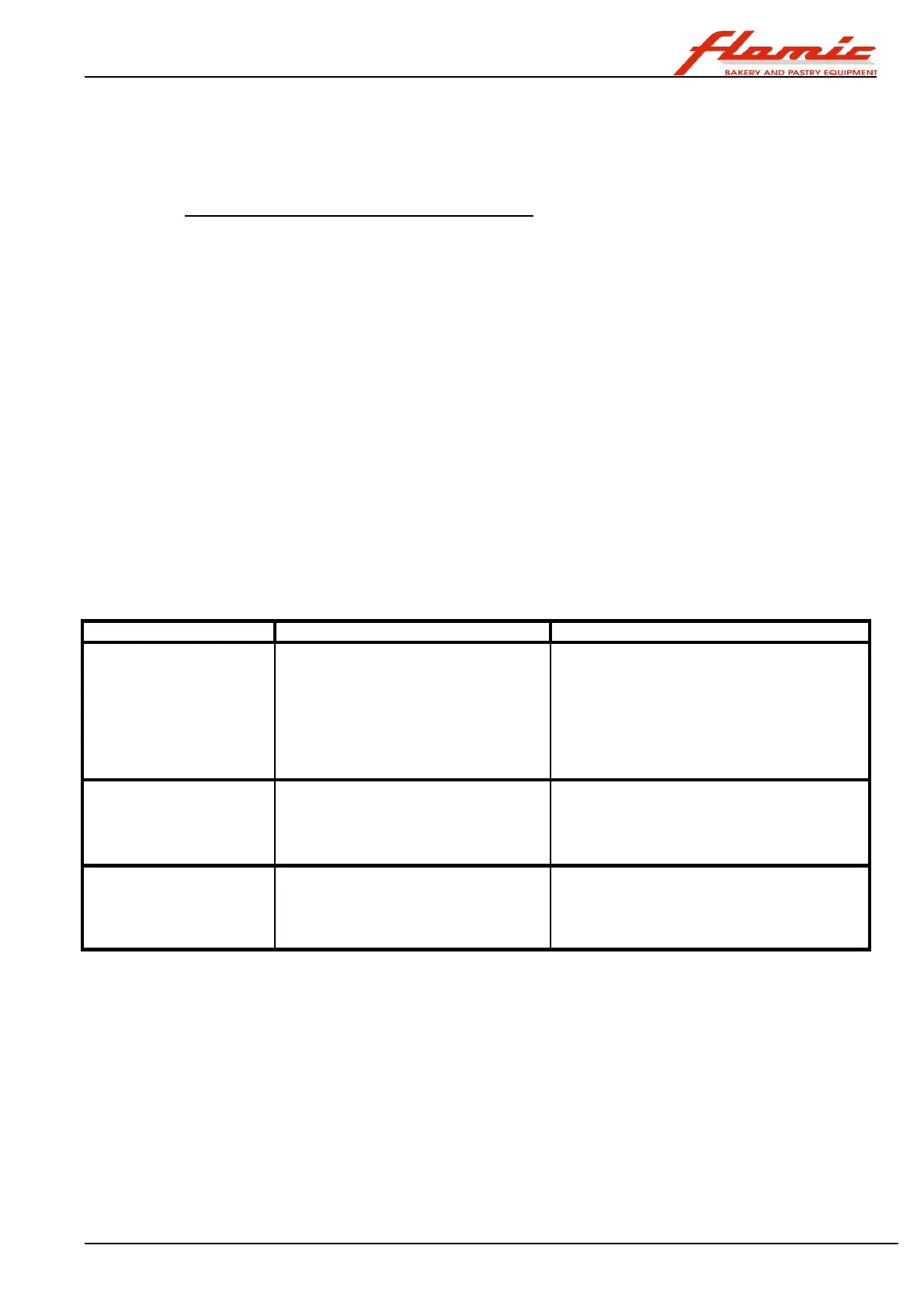

4.11 POSSIBLE FAILURES AND / OR FAULTS

Here we indicate some possible failures and/or faults that may occur. Any action taken must be carried out in

compliance with the instructions, if any, and in any case only after having taken the safety precautions

referred to in section 4.1.

The machine does not

turn on

• No power

• Electrical protection device tripped

(e.g. thermal switch)

- Check that the plug is properly inserted,

that the main power switch is in the I (ON)

position and that the safety devices of the

premises power supply have not tripped.

Reset if necessary

- Reset the safety device that has tripped

(special/extraordinary maintenance)

The machine doesn’t start

• An interlocked guard is not

completely lowered

• A micro switch associated with one

of the guards is faulty

- Lower the guard completely

- Have it replaced (special/extraordinary

maintenance). See section 4.9

There are folds and/or

tears in the sheet of

dough

• Conveyor speeds are not uniform

• Rollers dirty

- Check and if necessary, adjust the tension

of the belt(s)

- Clean the rollers and if necessary, clean or

replace the scrapers. See section 4.10

4.12 SPARE PARTS

To order replacement parts, contact the manufacturer or the dealer from whom the machine was purchased.

Provide a brief description of the part and/or its use and always specify serial number of the machine.

For transmission belts and chains see section 4.3 and section 4.7respectively.

4.13 PROLONGED STOP OR TAKING THE MACHINE OUT OF SERVICE

If the machine is not to be used for a long time or is to be taken out of service, disconnect it from the mains

power supply.

Take it to a suitable place and clean it completely (see section 4.10). If necessary, place the tables in the upright

position (see section 3.6) and cover the entire machine with waterproof sheets to protect it from atmospheric

agents, dust, insects, rodents etc. Make sure that it is protected from impact and that it cannot be tampered with

or damaged in any way etc.

When it is put back into service it should be inspected carefully to make sure that it is integral and you should

proceed as if it was the first time it was put into service.

Loading...

Loading...