FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

38

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

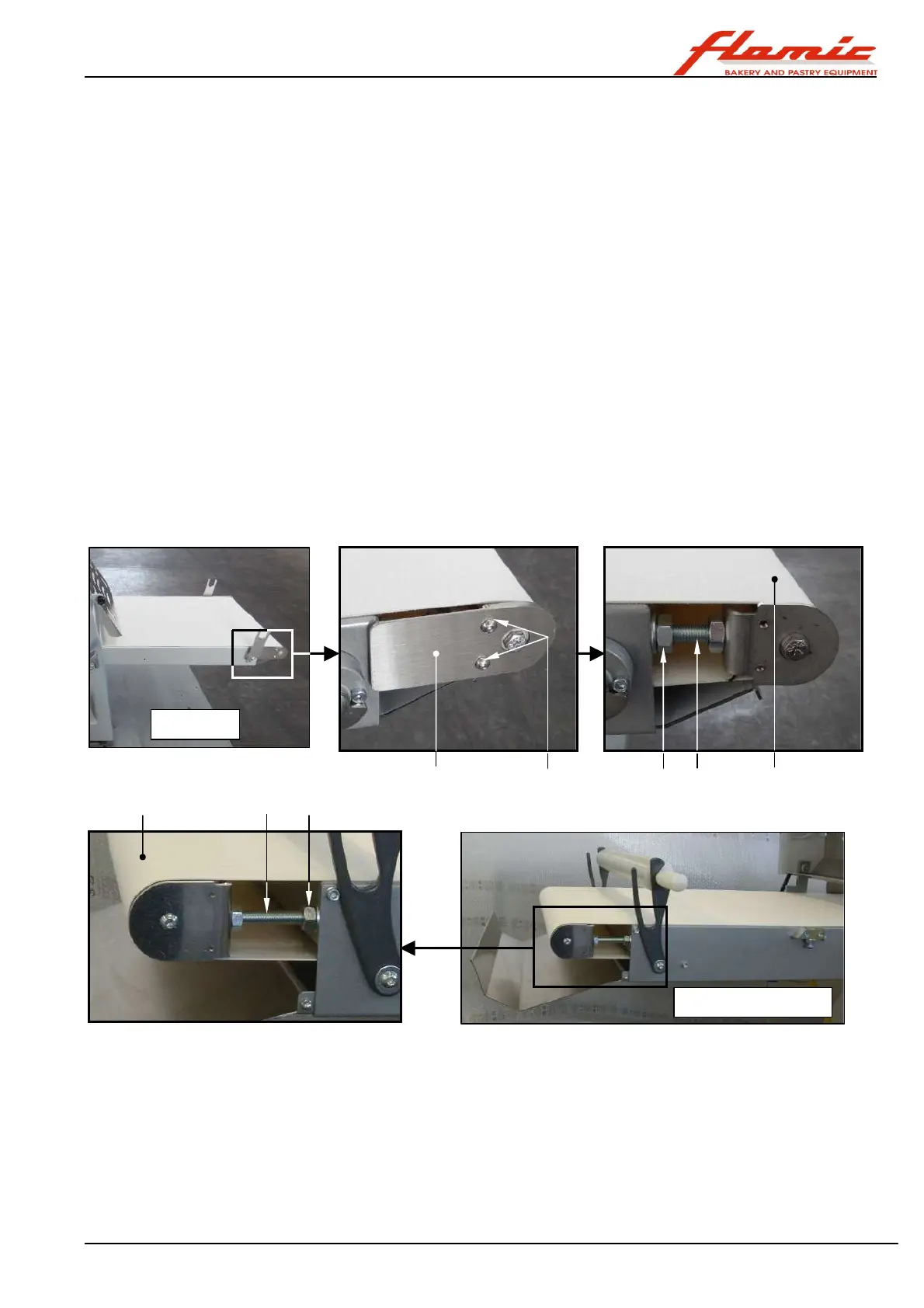

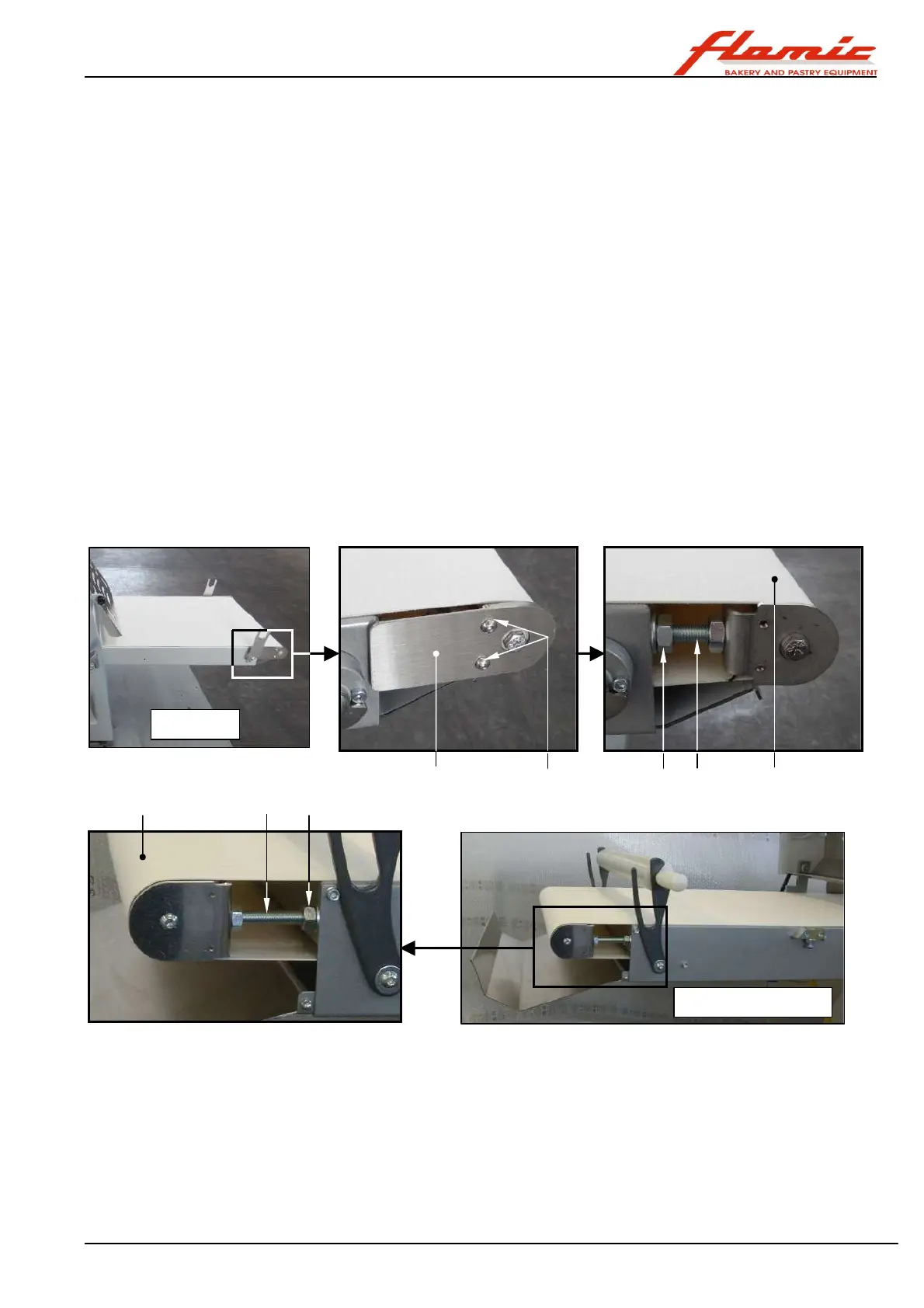

4.4 ADJUSTING THE TENSION AND CENTRING OF THE CONVEYOR BELTS

To ensure the best performance and results, the tension of both conveyor belts must be properly regulated so

that the dough moves smoothly and uniformly as it passes through the various rolling stages. Even small

variations in the speed of one or both belts during the rolling process can subject the dough to abnormal stress

and cause it to tear. This decreases the quality of the dough sheet or can even make it impossible to produce it.

The thinner the sheet, the more evident this problem is.

The tension of the conveyor belts should be checked and adjusted whenever you notice that they move

unevenly.

With reference to Figure 32, using an open-end spanner, turn the nuts ref. 1 on each side of the bench in order

to move the roller ref. 2 forwards/backwards via the threaded rods ref. 3. Tension the conveyor belts as much as

necessary (or slightly more) so that their speed is uniform both when empty and unloaded. Excessive tension

would not provide any advantage but could cause rapid and abnormal wear.

Depending on the destination or the contractual agreements, the machine may be fitted with plates ref. 4

fastened with screws ref. 5. These have to be removed in order to carry out adjustments.

Once adjustments have been completed, replace the plates ref. 4 on both sides and fasten them using the

screws ref. 5.

The same devices are also used to adjust the centring of the belt on the bench. With respect to this, it should be

remembered that when in motion, a conveyor belt tends to move towards the side that is less taught. It is

therefore very important that the tension is the same on both sides of the belt.

The tension and/or centring of the belts has to be carried out while the machine is in operation. Only in this way

is it possible to see the effect of any adjustments.

WARNING! Do not place your hands in the zone in which the roller and belt converge to avoid the risk of

trapping and dragging. Also, hold the open-end spanner firmly. If it were to fall onto the belt while it is in

motion, it could cause serious damage to the machine.

Figure 32 - Conveyor belt tensioning and centring system

1

1 2 3

4 5 3 2

Loading...

Loading...