Victor Xu Page 75 12 Jan. 2011

Copyright 2011 © Shenzhen Runtianzhi Image Technology, Co., Ltd.

http://www.floradigital.com

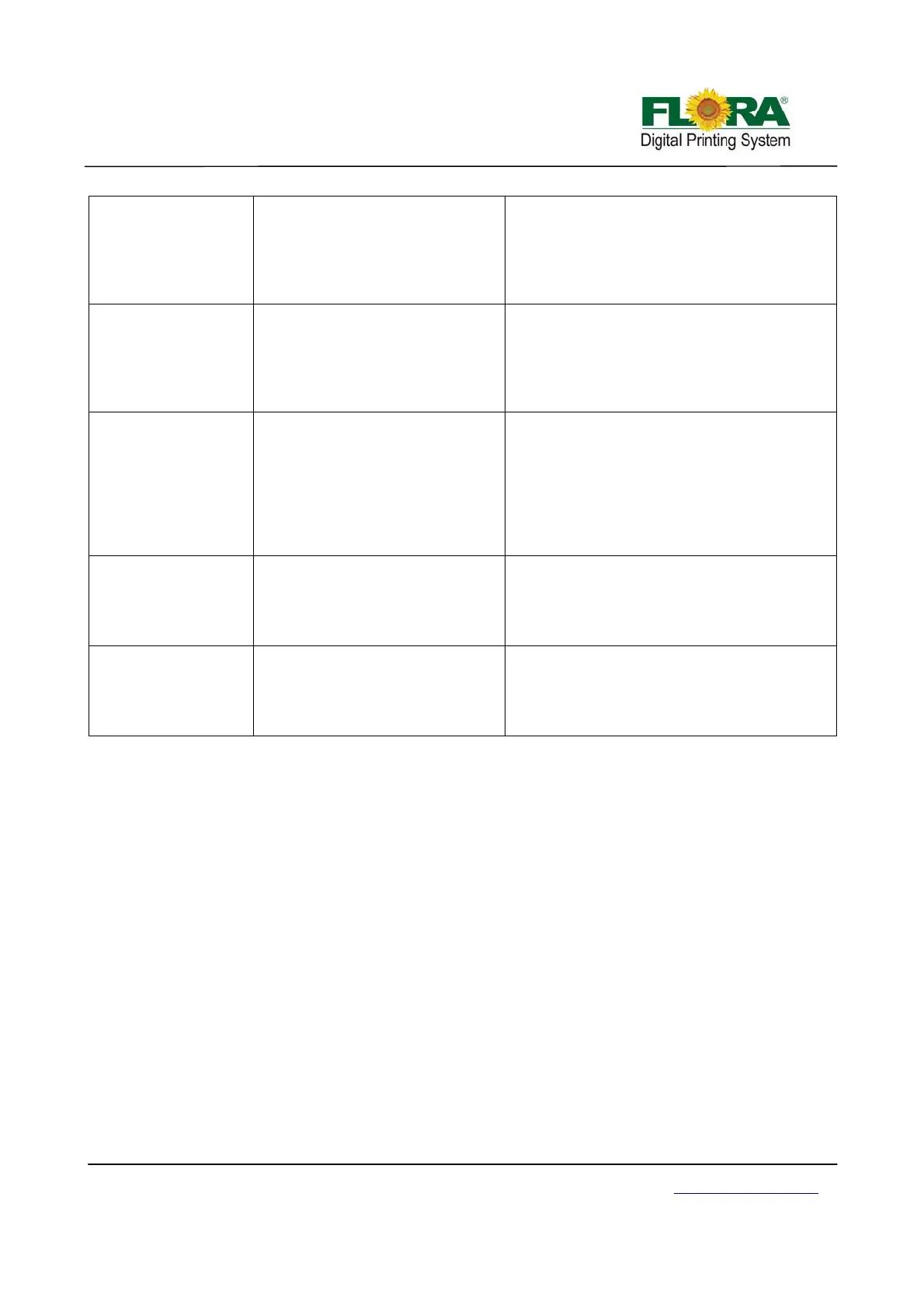

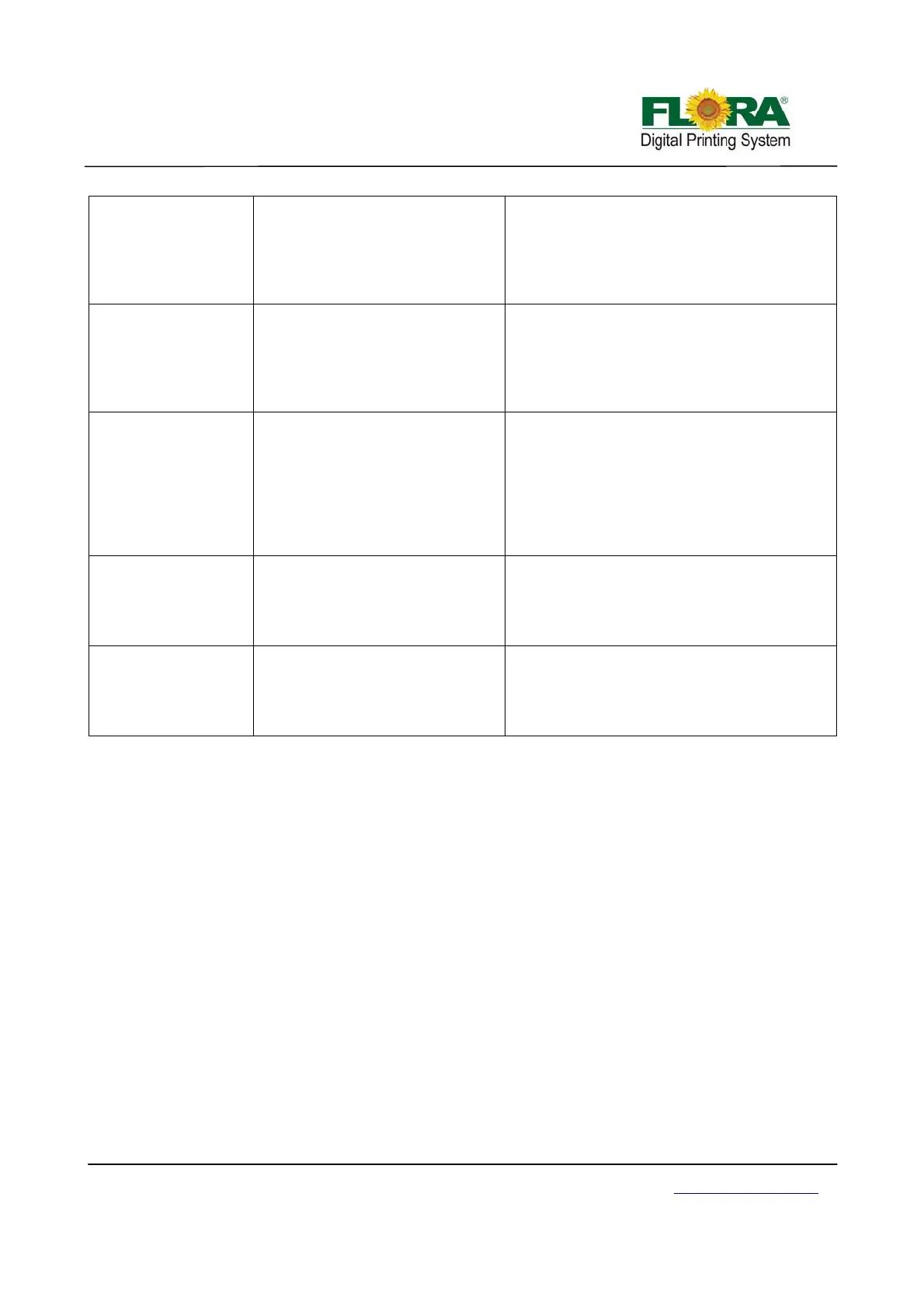

Inconsistent step

align problem

o Feeding of the Pinch Roller

is not equal

o Worn-out Gear Box

Assembly

o Defective Motor Encoder

o Worn-out Timing Belt

Adjust the tension of the Pinch Roller (see

Pinch Roller

Adjustment Procedure)

Replace worn-out Reducer Gear Box

Replace Y-Axis Servo Motor

Replace Timing Belt

Vertical Banding

on the right side

portion of the

machine

o Raster Strip might have

scratches on that portion

o Loose connection on the

Print head Cable Data lines

o Tension on energy chain

assembly

Replace the Raster Strip

Fix loosed Print head Cable Data lines

Fix/replace the energy chain

Re-setup and cabling on the energy

chain

Carriage

suddenly stops

during operation

X-alignment

problem during

printing

o Raster Strip is too dirty

o Portion of Raster Strip has

severe scratches

o Defective Raster Strip

o Defective Raster Encoder

o Raster Encoder is not

properly setup with raster

strip

Clean Raster Strip .

Replace defective Raster Strip

Replace defective Raster Encoder

Perform Raster Alignment

Portion of the

RIPed image

was not printed

o The RIPed image dimension

is almost /more than

2000in/50m.

o The RIPed image file is more

than 4G bytes

Reduce the size to be RIPed to

manageable size to avoid RIPing error

Output size of

the image print is

not same with

the defined

image dimension

o Tension Roller problem

o Needs to perform Output

Size Compensation

Adjust/setup the roller tension properly

See page 48 for proper procedure in

using Output Size Compensation

Loading...

Loading...