830

Users Manual

104

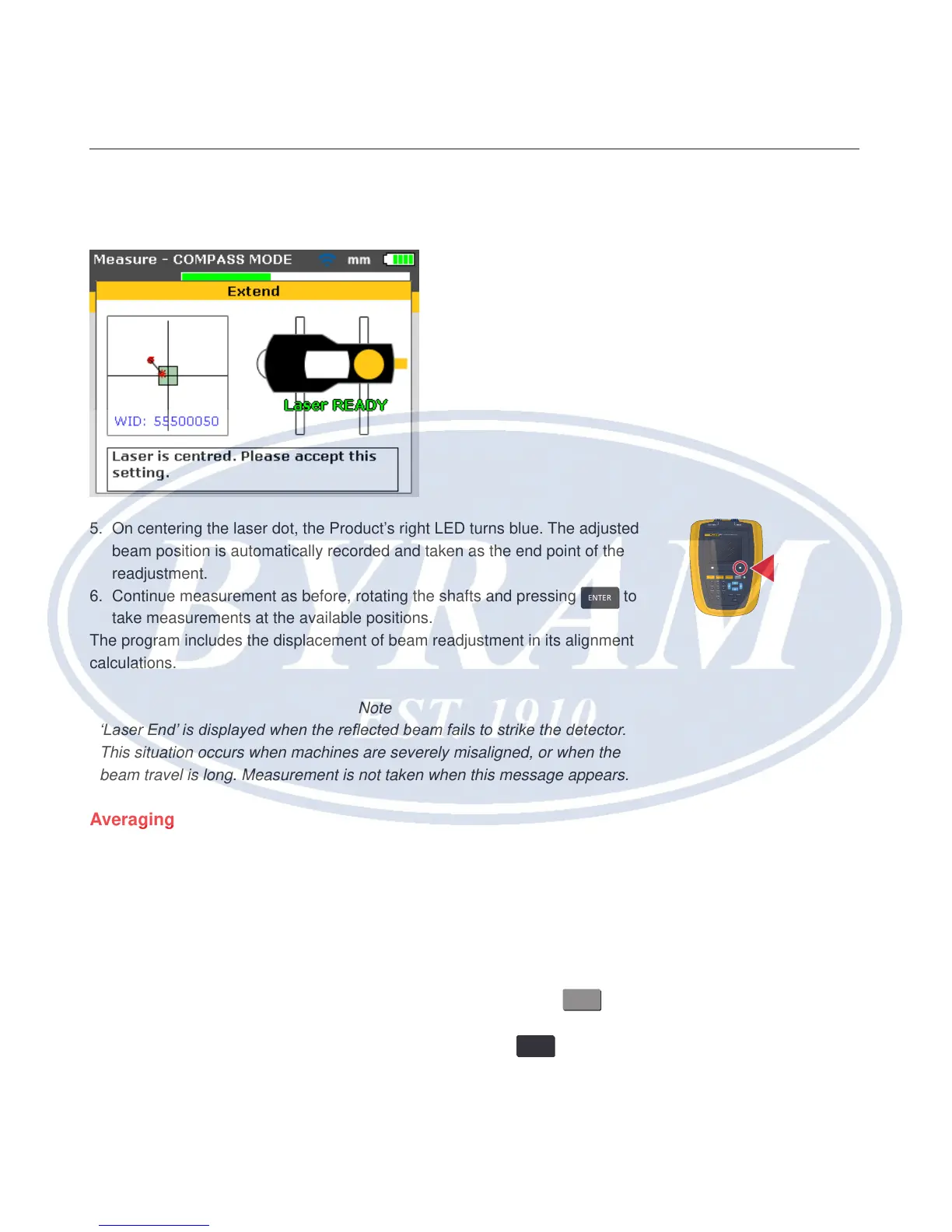

4. Readjust the beam into the target square using the yellow prism knob and the

metal thumbwheel.

5. On centering the laser dot, the Product’s right LED turns blue. The adjusted

beam position is automatically recorded and taken as the end point of the

readjustment.

6. Continue measurement as before, rotating the shafts and pressing

ENTER

to

take measurements at the available positions.

The program includes the displacement of beam readjustment in its alignment

calculations.

Note

‘Laser End’ is displayed when the reected beam fails to strike the detector.

This situation occurs when machines are severely misaligned, or when the

beam travel is long. Measurement is not taken when this message appears.

Averaging

In certain industrial conditions, it may be necessary to increase the number

of measurements to be averaged when taking readings to attain the desired

accuracy. Particular cases include applications with increased machinery

vibration. An increased averaging also improves the accuracy when measuring

sleeve bearings, white metal bearings and journal bearings.

The number of individual readings which are averaged together to form one

measurement are set via the “Measurement options” screen. Press

MENU

to

access the menu. While in the menu screen use the navigation keys to highlight

the ‘Measure options’ icon and conrm selection by pressing

ENTER

. The

“Measurement options” screen opens.

830

LASER ALIGNMENT TOOL

SETUP MEASURE

DIAGNOSE MENU

CLEARENTER

BACK

1

2

ABC

3

DEF

4

GHI

5

JKL

6

MNO

7

PQRS

8

TUV

9

WXYZ

+

-

0

space

.

/

.

Loading...

Loading...