4 Initial Startup

4.1 General information

IMPORTANT: First start up of boiler system shall be carried

out only in attendance of an authorized installer or

manufacturer’s representative

During normal operation of boiler all surfaces and control handles behind

insulation door get hot. Touching hot surfaces can cause serious burns!

Additionally there is the risk of injuries by splinters of fire wood!

When heating up the boiler:

Always wear protective gloves

Always use control handles for open boiler doors

IMPORTANT: Condensation within the boiler during first start-

up does not indicate a fault! If this occurs, clean up using a

cleaning rag.

4.1.1 Before heating up for the first time

Check the system pressure of the heating system.

Check that the heating system is completely vented.

Check if the safety devices are present and working correctly.

Check that there is sufficient combustion air supply and venting.

Check the contact seals of the boiler.

All doors and inspection openings must be tightly sealed!

Check that all Door Contact Switch’s are working correctly.

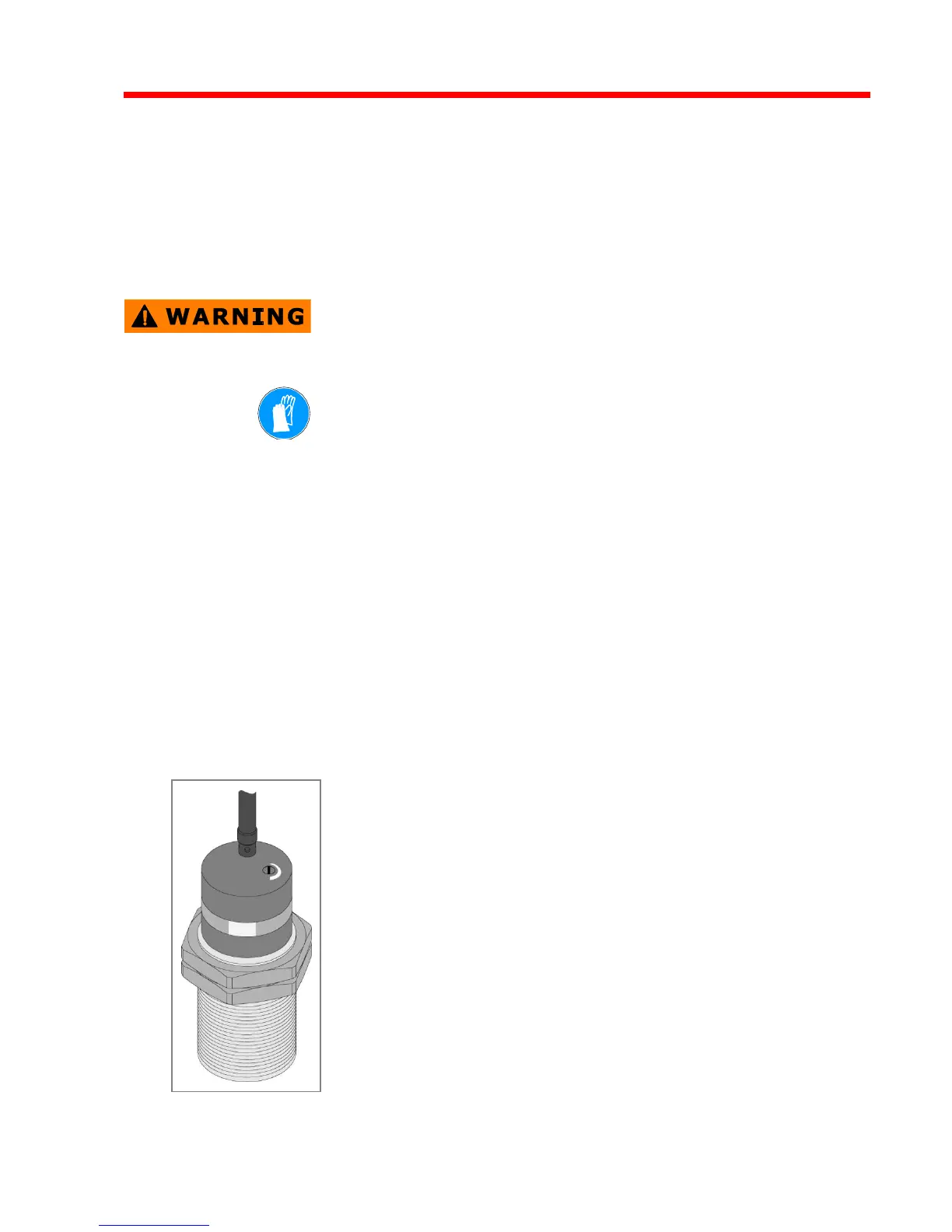

4.2 Setting “Max Level” sensor

In delivery configuration, the factory settings of the sensor are secured

with a seal. Changes to the settings should only be carried out by

qualified technicians.

The monitoring LED (1) should only light up when identifying

materials!

If the monitoring LED stays on permanently, the sensitivity is set

too high!

Reduce the sensitivity by turning the adjusting screw (2) to the

left.

If the monitoring LED does not react when pellets are being fed in,

the sensitivity is set too low!

Increase the sensitivity of the adjusting screw by turning to the

right.

Loading...

Loading...