Plumbing Systems

Fröling Heizkessel- und Behälterbau Ges.m.b.H, Industriestrasse 12, A-4710 Grieskirchen Page 51

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com M0930207

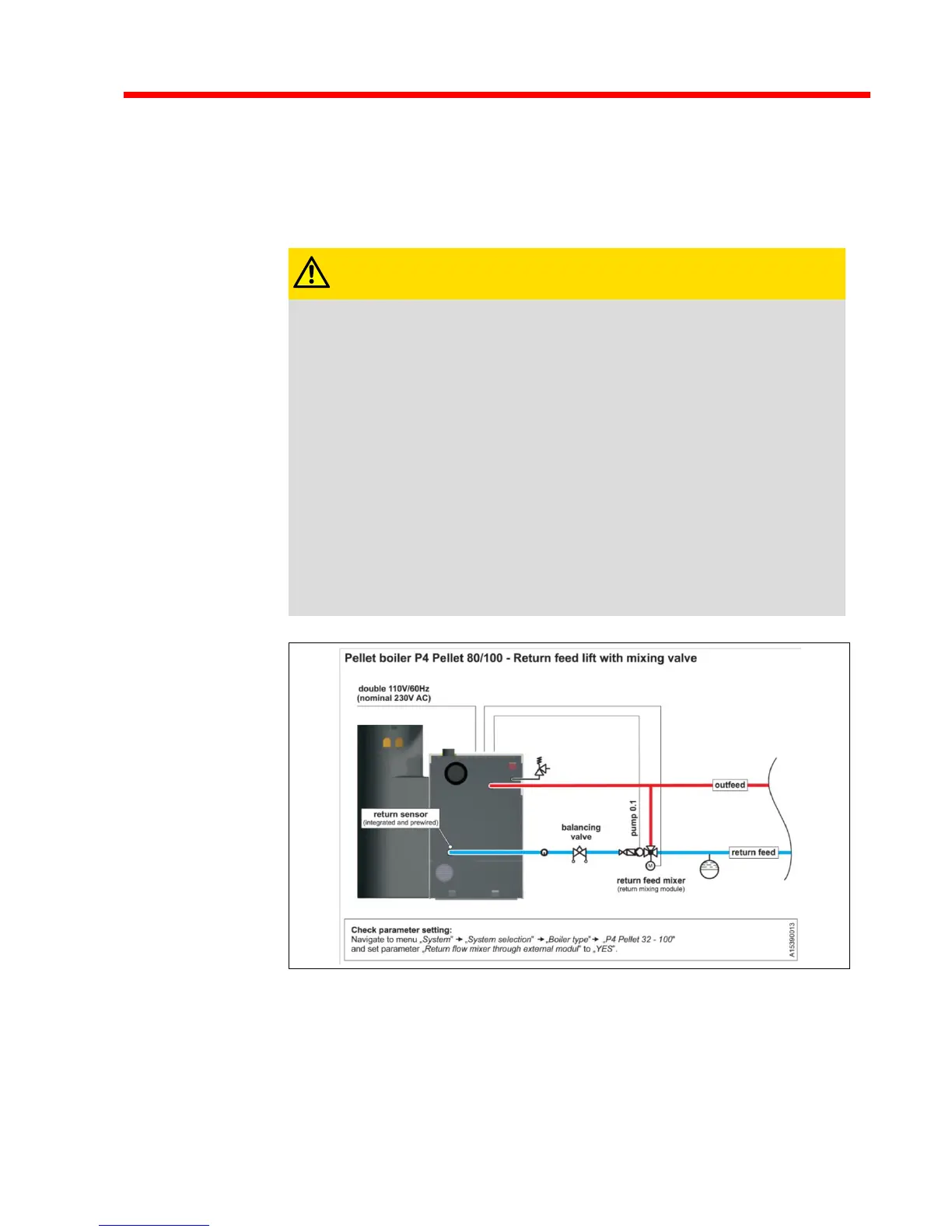

5.6 Return temperature control (Only for the model 80/100)

If the hot water return is below the minimum return temperature-usually

during cold start-up or when charging a storage tank, some of the hot water

must be mixed into the return flow. The model 80/100’s boiler control has this

function and must be utilized in order to prevent shortened boiler life and loss

of warranty coverage.

Risk of dropping flue gas temperature below the dew point / condensation formation if

operated without return temperature control

Condensation water forms an aggressive condensate when combined with combustion

residue, leading to damage of the boiler

At low outside temperature condensation water may freeze at chimney outlet and will lead

to insufficient chimney draft with restrictions to boiler power including possibility of system

break down

We recommend that you use a return temperature control.

❒ The minimum return temperature is 140°F (60°C). We recommend fitting a 3-way

mixing valve including valve motor (pulse control) and a temperature sensor.

Automatic closed loop control for return temperature is provided within the boiler

control system.

5.7 Supply and Return Connections

Please pay attention to connection labeling on back of boiler. For P4 Pellet 8-

38 models the supply connection is the lower connection and on the P4 Pellet

48-100 models the supply connection is the upper connection. Only the P4

Pellet 80/100 will need return temperature control.

Loading...

Loading...