108

Follow the displayed instructions

Press the torch trigger / select "Next" / press the adjusting dial

After a successful measurement, the current values are displayed.

Select "Finish" / press the adjusting dial

Process parame-

ters for TIG /

MMA/SMAW Set-

up

The following process parameters can be set and displayed for the TIG and rod electrode

welding process:

Process parameters for MMA welding:

8

9

10

Starting current time

for setting the length of time the starting current is to be active

Unit s

Setting range 0.0 - 2.0

Factory setting 0.5

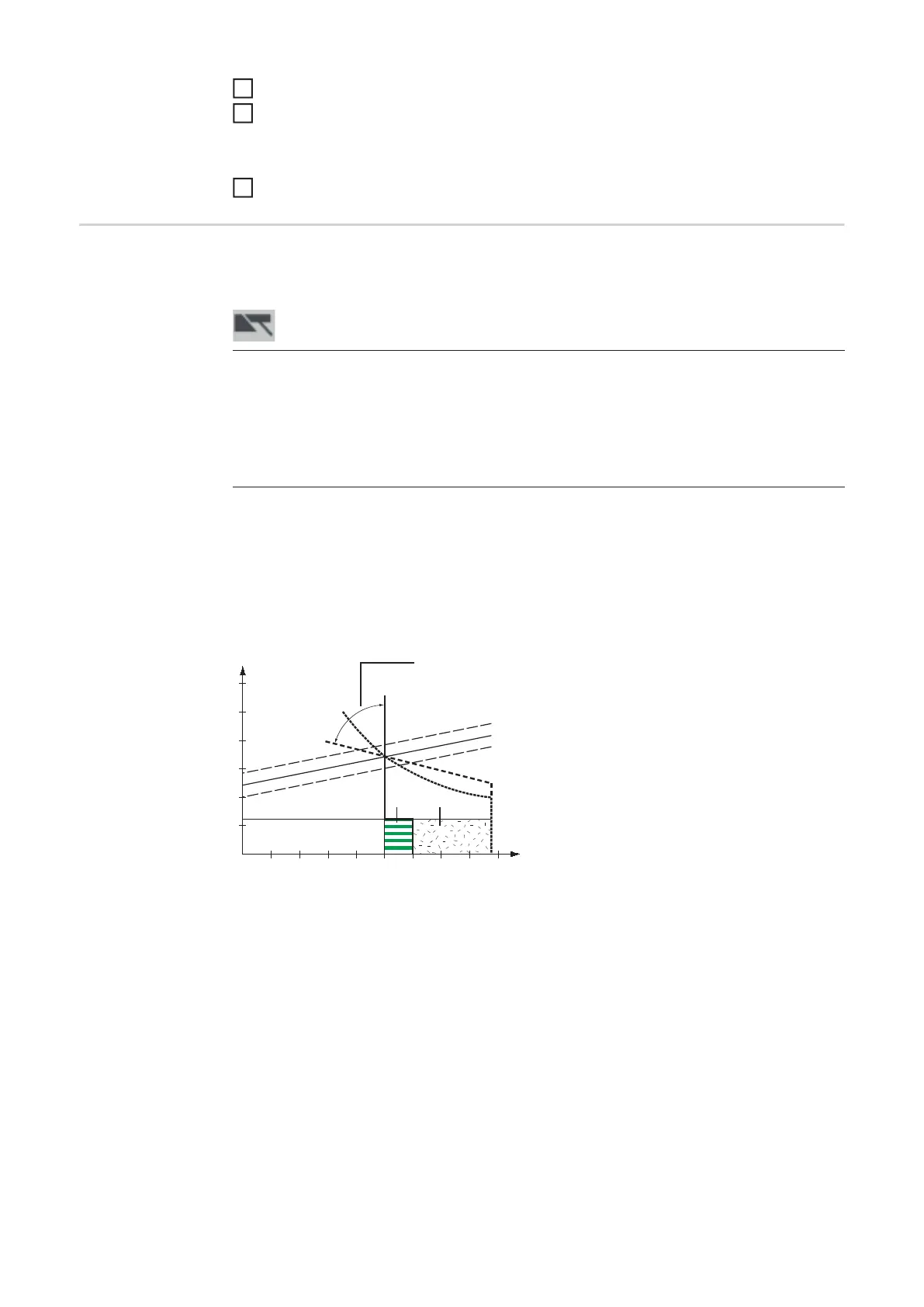

Characteristic

for selecting the electrode characteristic

Unit - / A/V / -

Setting range I-constant / 0.1 - 20.0 / P-constant

Factory setting I-constant

(1) Load line for rod electrode

(2) Load line for rod electrode where

arc length is increased

(3) Load line for rod electrode where

arc length is reduced

(4) Characteristic where "I-constant"

parameter is selected (constant

welding current)

(5) Characteristic where "0.1 - 20" pa-

rameter is selected (drooping

characteristic with adjustable

slope)

(6) Characteristic where "P-constant"

parameter is selected (constant

welding power)

(7) Example of pre-set arc-force dynamic where characteristic (4) is selected

(8) Example of pre-set arc-force dynamic where characteristic (5) or (6) is selected

I-constant

(constant welding cur-

rent)

- If the "I-constant" parameter is set, the welding current will

be kept constant, irrespective of the welding voltage. This

results in a vertical characteristic (4).

- The "I-constant" parameter is particularly suitable for rutile

electrodes and basic electrodes.

0040 200100 300 I (A)

U (V)

con - 20 A / V

(4)

(5)

(6)

(7) (8)

(1)

(2)

(3)

Loading...

Loading...