52

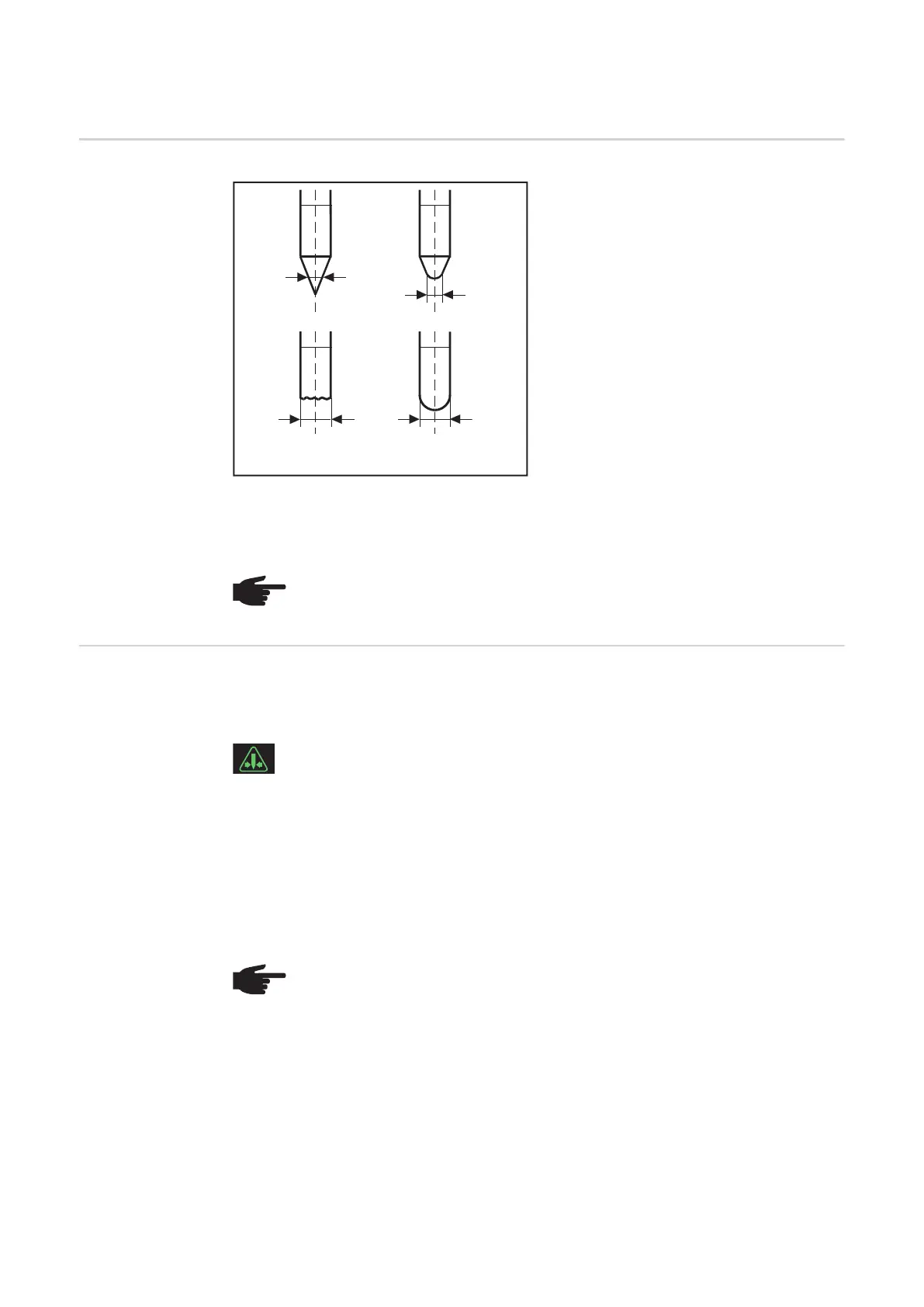

Cap shaping and cap overloading

Cap shaping

Cap overloading If the cap is overloaded, there is a risk of an excessively large cap forming on the tungsten

electrode. This will affect the ignition properties.

Possible causes of cap overloading:

- tungsten electrode diameter is too small

- main current value I

1

set too high

- the balance has been set too far towards "+"

Remedy:

- use a tungsten electrode with a larger diameter

- reduce the main current and/or set the balance further towards "-"

For all other electrodes, the "Electrode overload" indicator must be treated as a reference

value.

(1) Before ignition

(2) After ignition

On MagicWave power sources, an auto-

matic cap-shaping function is available for

the TIG AC welding process:

- When the TIG AC welding process is

selected, activate automatic cap-

shaping

- The ideal cap for the specified diame-

ter of the tungsten electrode is

formed during welding start-up.

A separate cap-shaping operation on

a test workpiece is not necessary.

- The automatic cap-shaping function

is then reset and deactivated.

The automatic cap-shaping function

has to be activated separately for

each tungsten electrode.

NOTE! The automatic cap-shaping function is not necessary if a sufficiently large

cap has already formed at the tip of the tungsten electrode.

(2)(1)

If the cap is overloaded, the "Electrode overload" indicator will light up on the con-

trol panel.

NOTE! The "Electrode overload" indicator is fine-tuned to work with the following

tungsten electrodes:

- TIG AC welding: pure tungsten electrodes

- TIG DC welding: ceriated electrodes

Loading...

Loading...