64

Tacking function The tacking function is available for the TIG DC welding process.

When a time period is specified for the tAC (tacking) set-up parameter, the tacking function

is assigned to 2-step mode and 4-step mode. The operating sequence of the modes re-

mains unchanged.

During this period, a pulsed welding current is present that makes the weld pool run togeth-

er better when two parts are being tacked.

Mode of operation of tacking function when TIG DC welding is selected:

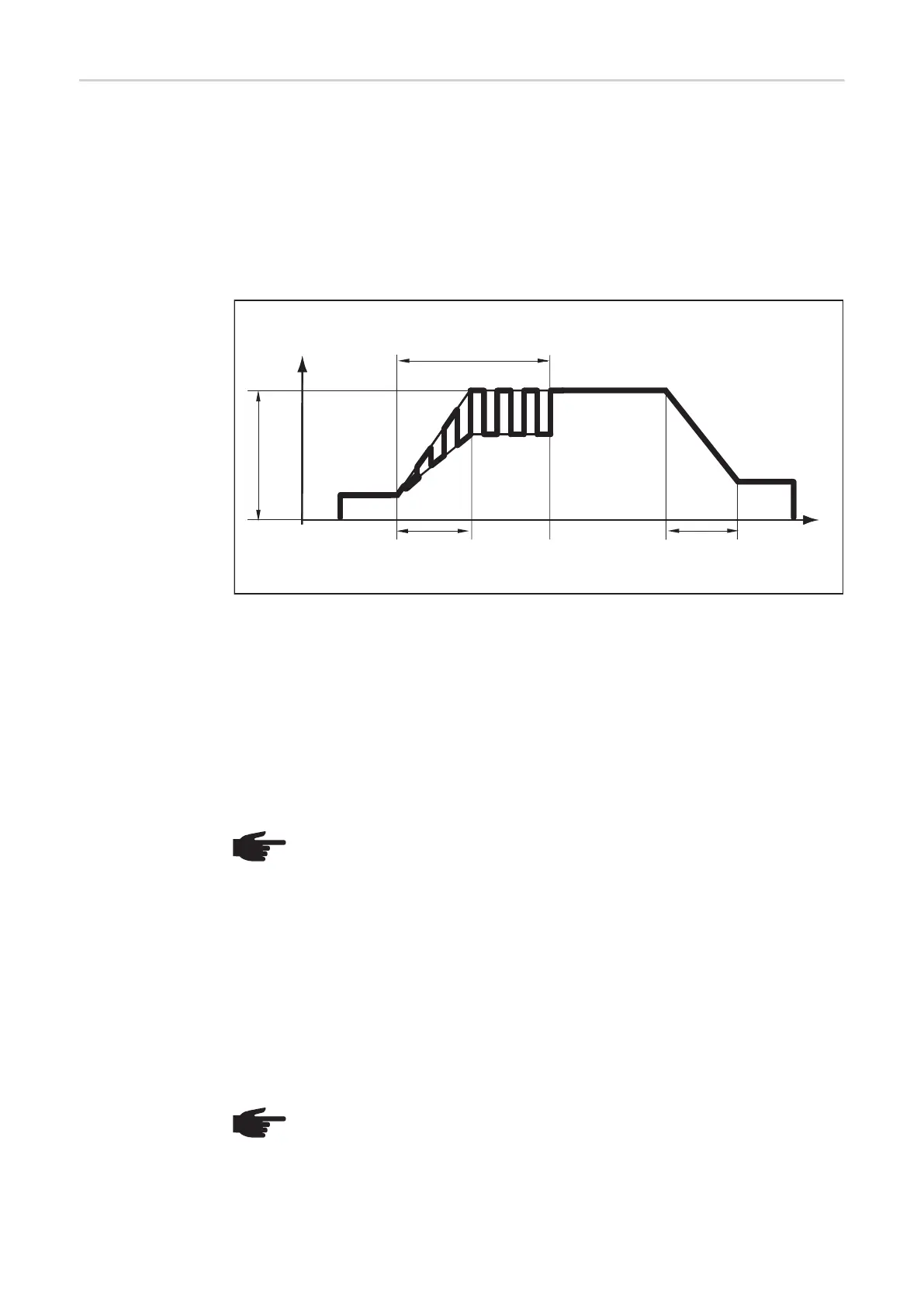

Tacking function - welding current curve

The pulsed welding current begins:

- after the end of the starting-current phase I

S

- With the upslope phase t

up

Depending on what tAC time has been set, the pulsed welding current may continue up to

and including the final current phase I

E

(tAC set-up parameter set to "ON").

After the tAC time has elapsed, welding continues at a constant welding current, and any

pulsing parameters that may have been set continue to be available.

Legend:

tAC Duration of pulsed welding current for the tacking process

I

S

Starting current

I

E

Final current

t

up

Upslope

t

Down

Downslope

I

1

Main current

NOTE! The following points apply to the pulsed welding current:

- The power source automatically regulates the pulsing parameters as a func-

tion of the specified main current I

1

- There is no need to set any pulsing parameters

NOTE! To set a specified tacking time, the tAC set-up parameter can be com-

bined with the SPt set-up parameter (spot welding time).

tAC

I

1

I

t

t

up

t

down

I

S

I

E

Loading...

Loading...