63

EN

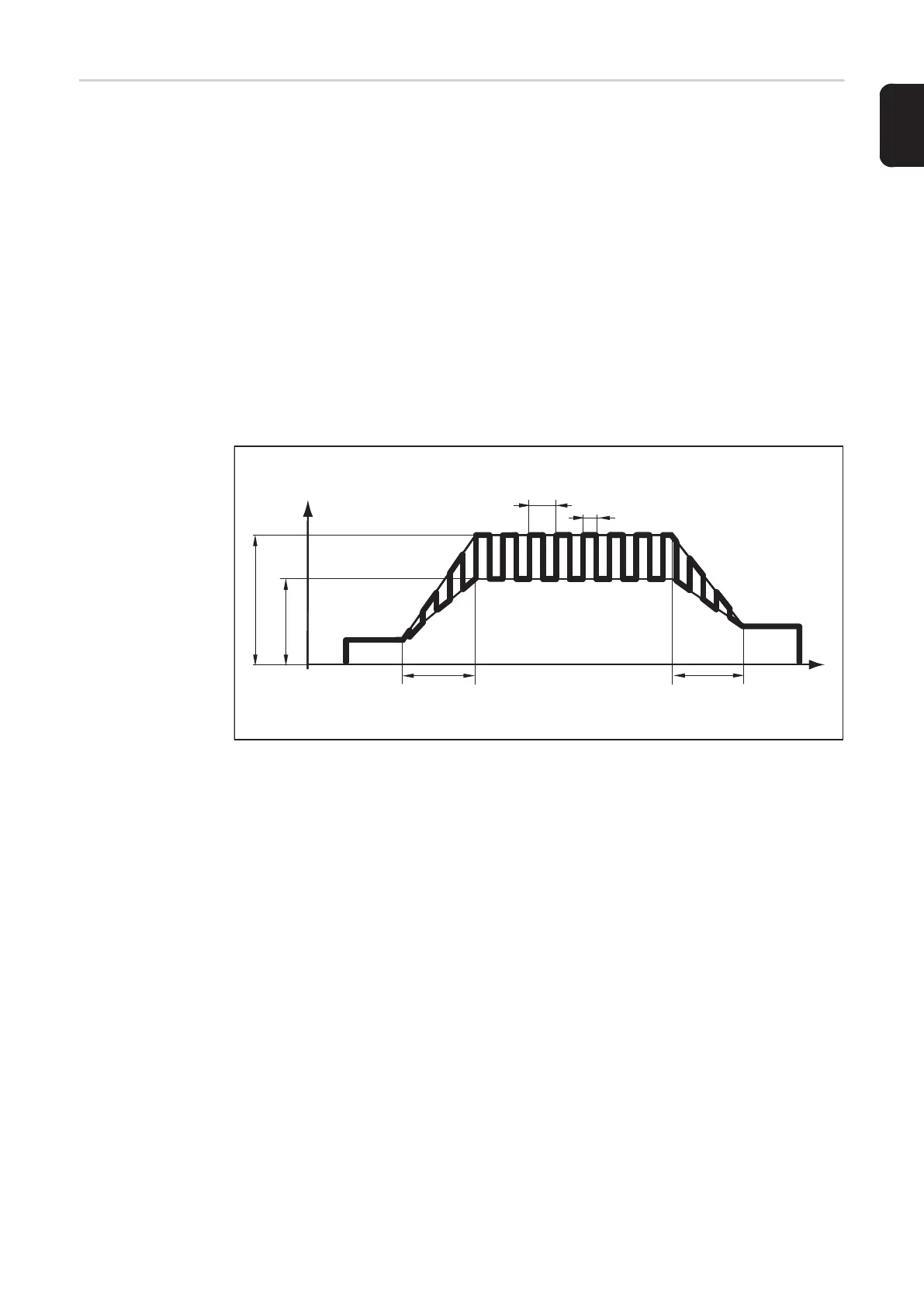

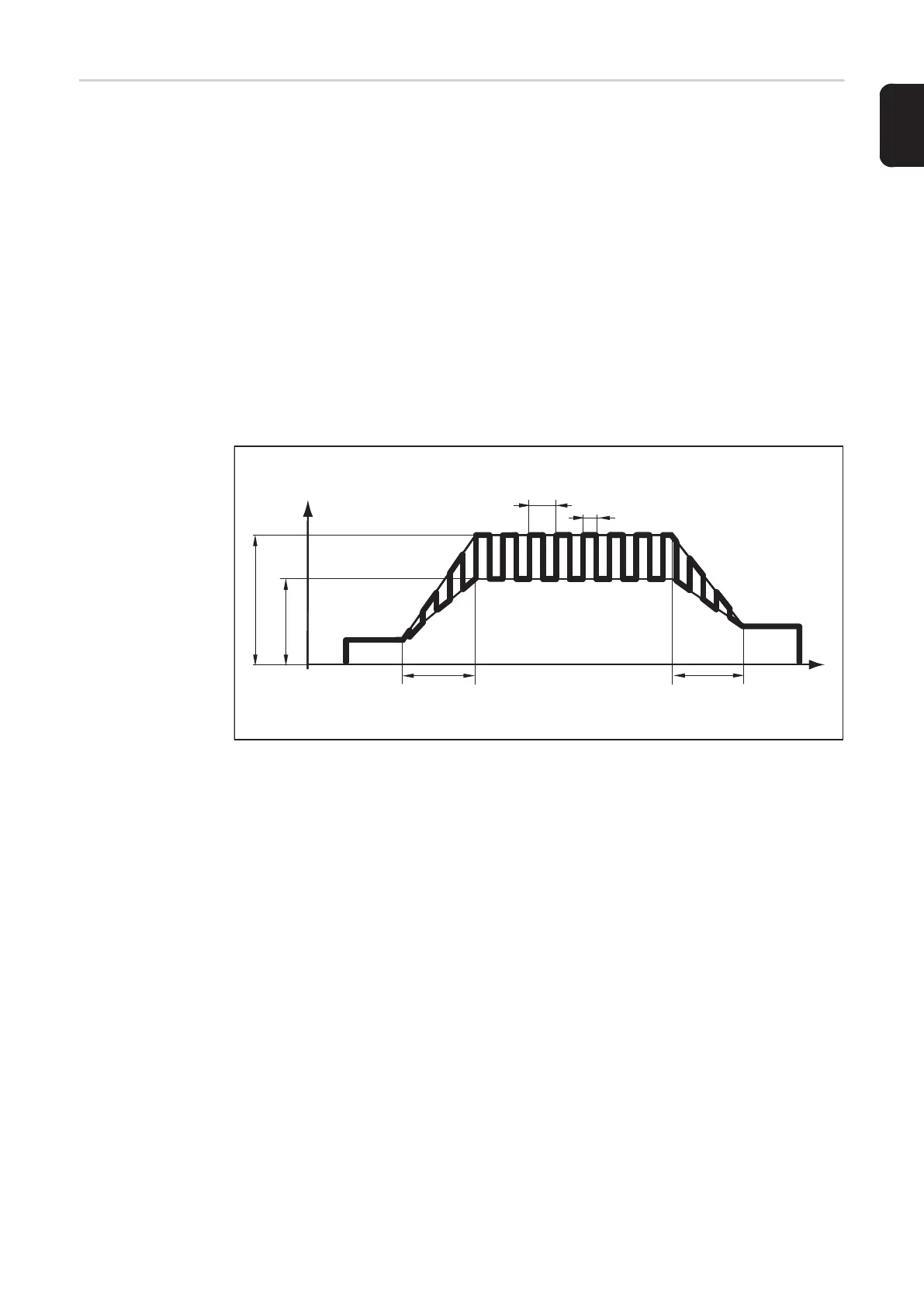

TIG pulsing The welding current set at the start of welding is not always ideal for the welding process

as a whole:

- if the amperage is too low, the base material will not melt sufficiently,

- if overheating occurs, the liquid weld pool may drip.

The TIG pulsing function (TIG welding with pulsing welding current) offers a remedy:

a low ground current I-G rises steeply to the significantly higher pulse current I1 and, de-

pending on the set dcY (duty cycle) time, drops back to the ground current I-G.

In TIG pulsing, small sections of the welding location melt quickly and then solidify again

quickly.

In manual applications using TIG pulsing, the welding wire is applied in the maximum cur-

rent phase (only possible in the low frequency range: 0.25 - 5 Hz). Higher pulse frequen-

cies are mainly used in automatic mode to stabilise the arc.

TIG pulsing is used for out-of-position welding of steel pipes or when welding thin sheets.

*) (1/F-P = time interval between two pulses)

Mode of operation of TIG pulsing when TIG DC welding is selected:

TIG pulsing - welding current curve

Legend:

I

S

Starting current F-P Pulse frequency *)

I

E

Final current dcY Duty cycle

t

up

Upslope I-G Ground current

t

Down

Downslope I

1

Main current

1/F-P

I

1

I-G

I

t

t

up

t

down

I

S

I

E

dcY

Loading...

Loading...