60

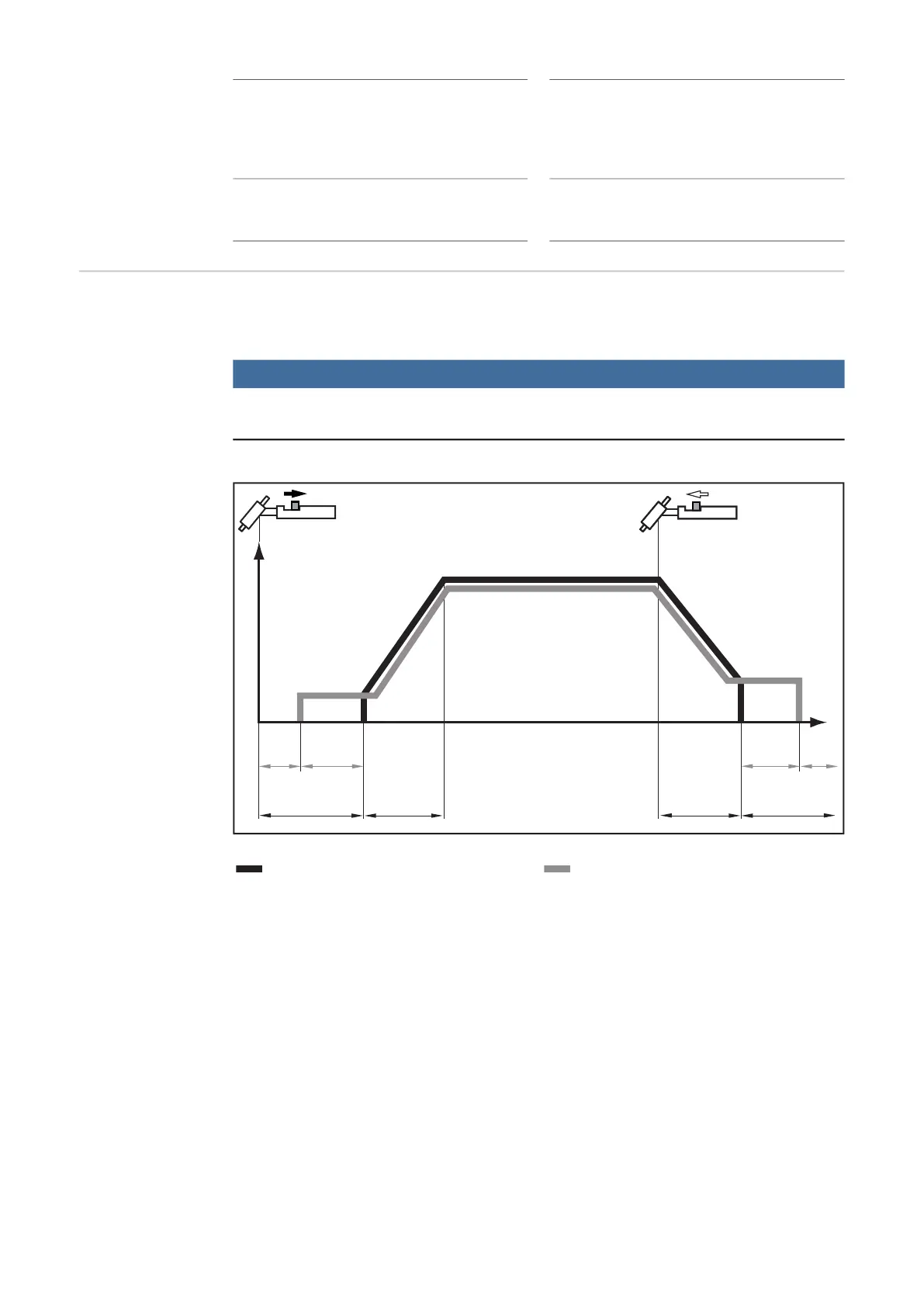

2-step mode - Welding: Pull back and hold the torch trigger

- End of welding: Release the torch trigger

NOTE!

To work in 2-step mode after it has been selected, the SPt setup parameter must be

set to "OFF" and the spot welding indicator on the control panel must not light up.

I

1

Main current phase (welding-current

phase): uniform thermal input into the

base material, whose temperature is

raised by the advancing heat

I

2

Reduced current phase: intermediate low-

ering of the welding current in order to pre-

vent any local overheating of the base

material

G-H

Gas post-flow time at maximum welding

current

G-L

Gas post-flow time at minimum welding

current

2-step mode

... Manual application ... Automatic application

I

t

I

1

G-L / G-HGPr t

up

t

down

I

S

GPr t

E

I

E

t

S

G-L

G-H

Loading...

Loading...