65

EN

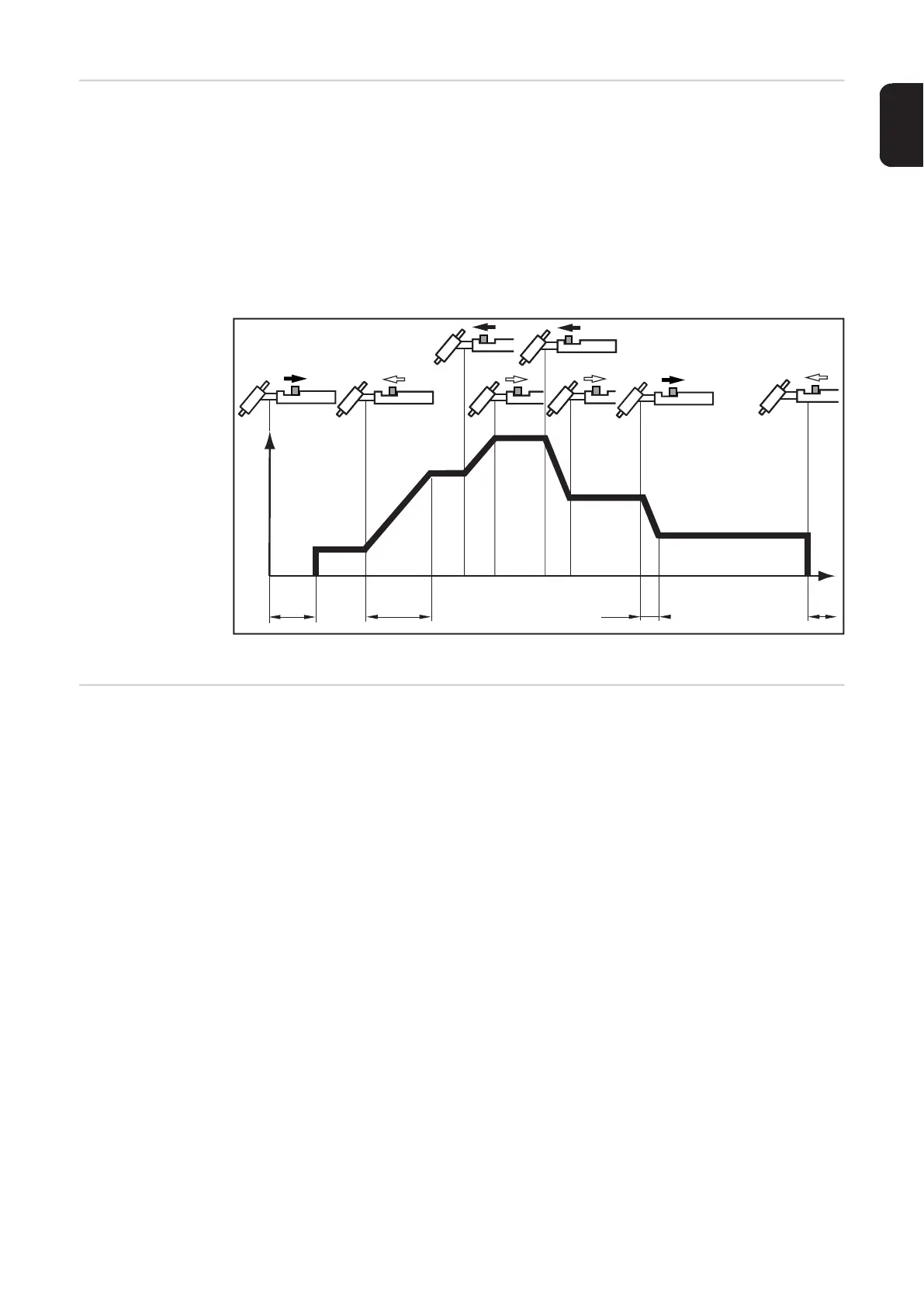

Special 4-step

mode:

variant 5

Variant 5 of the special 4-step mode is activated when the SFS set-up parameter is set to

"5".

Variant 5 allows the welding current to be increased and reduced without an up/down weld-

ing torch.

- The longer the torch trigger is held in the forward position during welding, the more the

welding current increases (up to the maximum).

- The welding current remains constant when the torch trigger is released.

- The longer the torch trigger is pushed forward again, the more the welding current de-

creases.

Special 4-step mode: variant 5

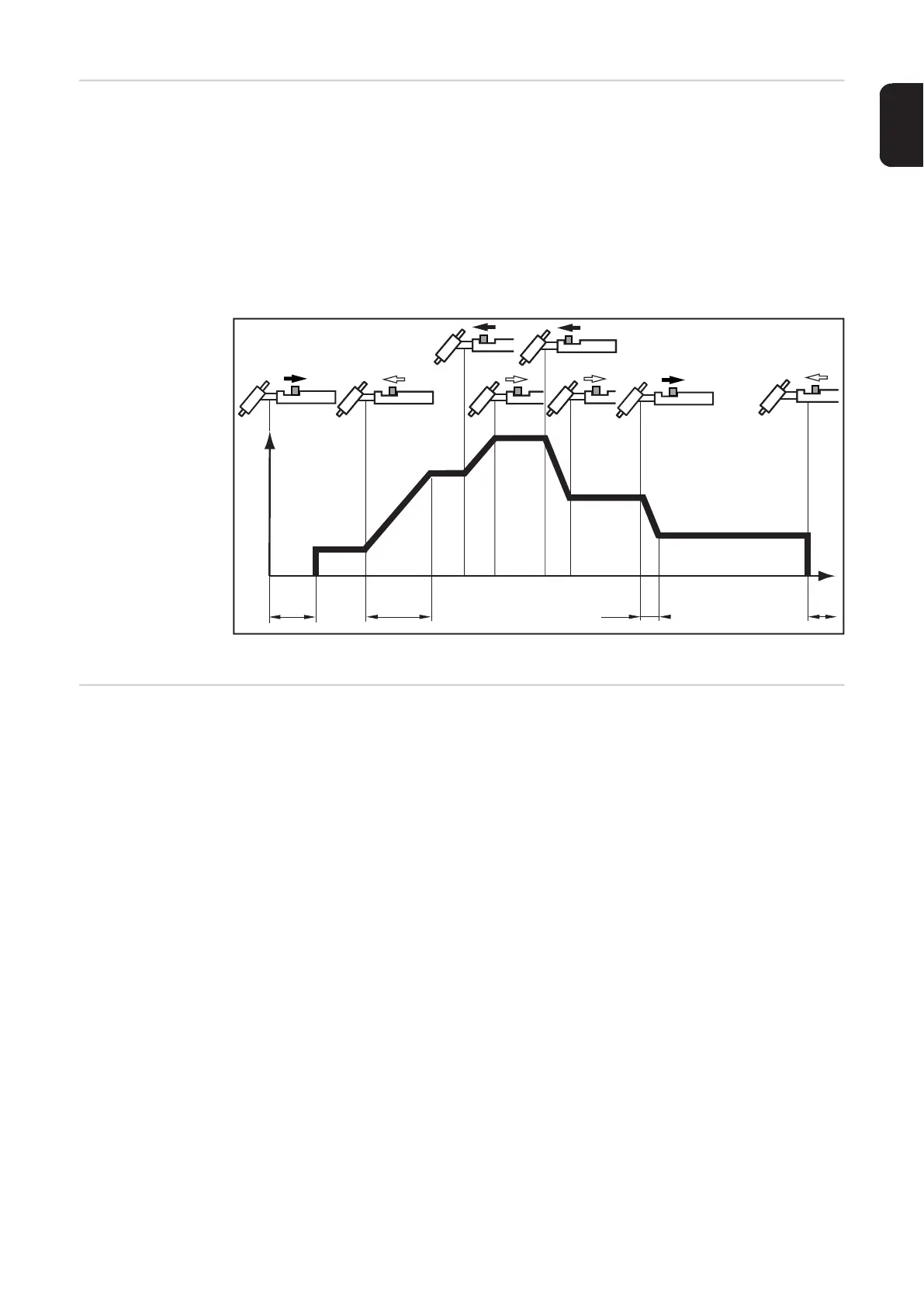

Special 4-step

mode:

variant 6

Variant 6 of the special 4-step mode is activated when the SFS set-up parameter is set to

"6".

- Welding start-up with starting current I

S

and upslope: Pull back and hold the torch trig-

ger

- Intermediate lowering to I

2

and changing from I

2

back to the main current I

1

: briefly

press (< 0.5 s) and release the torch trigger

- End the welding process: press the torch trigger for longer (> 0.5 s) and release.

The process is automatically ended after the downslope phase and the final current phase.

If the torch trigger is pressed briefly (< 0.5 s) and released during either the downslope

phase or the final current phase, then an upslope will take effect until it reaches the main

current and the welding process will continue.

GPr t

down

G-L

G-H

t

up

I

t

I

1

I

S

I

E

I

1

>

I

1

<

Loading...

Loading...