72

Igniting the arc

General To ensure the best ignition sequence in the TIG AC welding process, the MagicWave pow-

er sources take account of:

- the diameter of the tungsten electrode

- the current temperature of the tungsten electrode with reference to the preceding

welding and weld-off times

To ensure the ideal ignition sequence in TIG DC welding, MagicWave power sources are

equipped with RPI (Reverse Polarity Ignition).

At the start of welding, the polarity is briefly reversed. Electrons emerge from the workpiece

and strike the tungsten electrode. This results in the tungsten electrode heating up rapidly

- an essential prerequisite for optimum ignition properties.

For more information about the RPI function, please refer to the "Set-up menu DC: level 2"

section in the set-up parameters chapter.

Igniting the arc

using high fre-

quency

(HF ignition)

CAUTION!

Risk of injury due to shock caused by electric shock

Although Fronius devices comply with all relevant standards, high-frequency ignition can

transmit a harmless but noticeable electric shock under certain circumstances.

► Use prescribed protective clothing, especially gloves!

► Only use suitable, completely intact and undamaged TIG hosepacks!

► Do not work in damp or wet environments!

► Take special care when working on scaffolding, work platforms, in forced positions

(out-of-position welding), in tight, difficult to access or exposed areas!

HF ignition is activated when a time value has been set for the HFt setup parameter.

The HF ignition indicator lights up on the control panel.

Compared with touchdown ignition, HF ignition eliminates the risk of contamination of the

tungsten electrode and the workpiece.

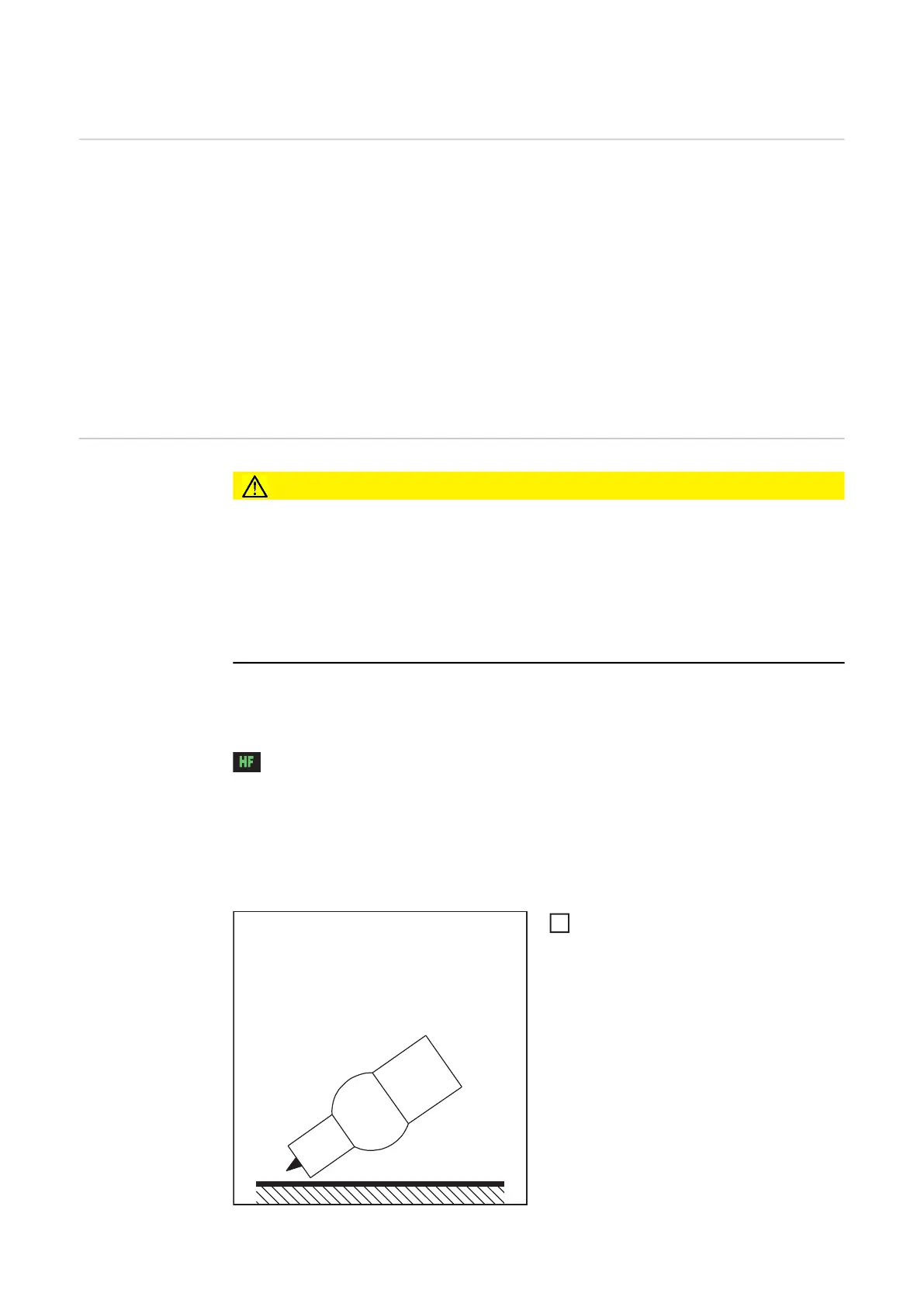

Procedure for HF ignition:

Place the gas nozzle down on the igni-

tion location so that there is a gap of

approx. 2 to 3 mm (5/64 to 1/8 in.) bet-

ween the tungsten electrode and the

workpiece

Loading...

Loading...