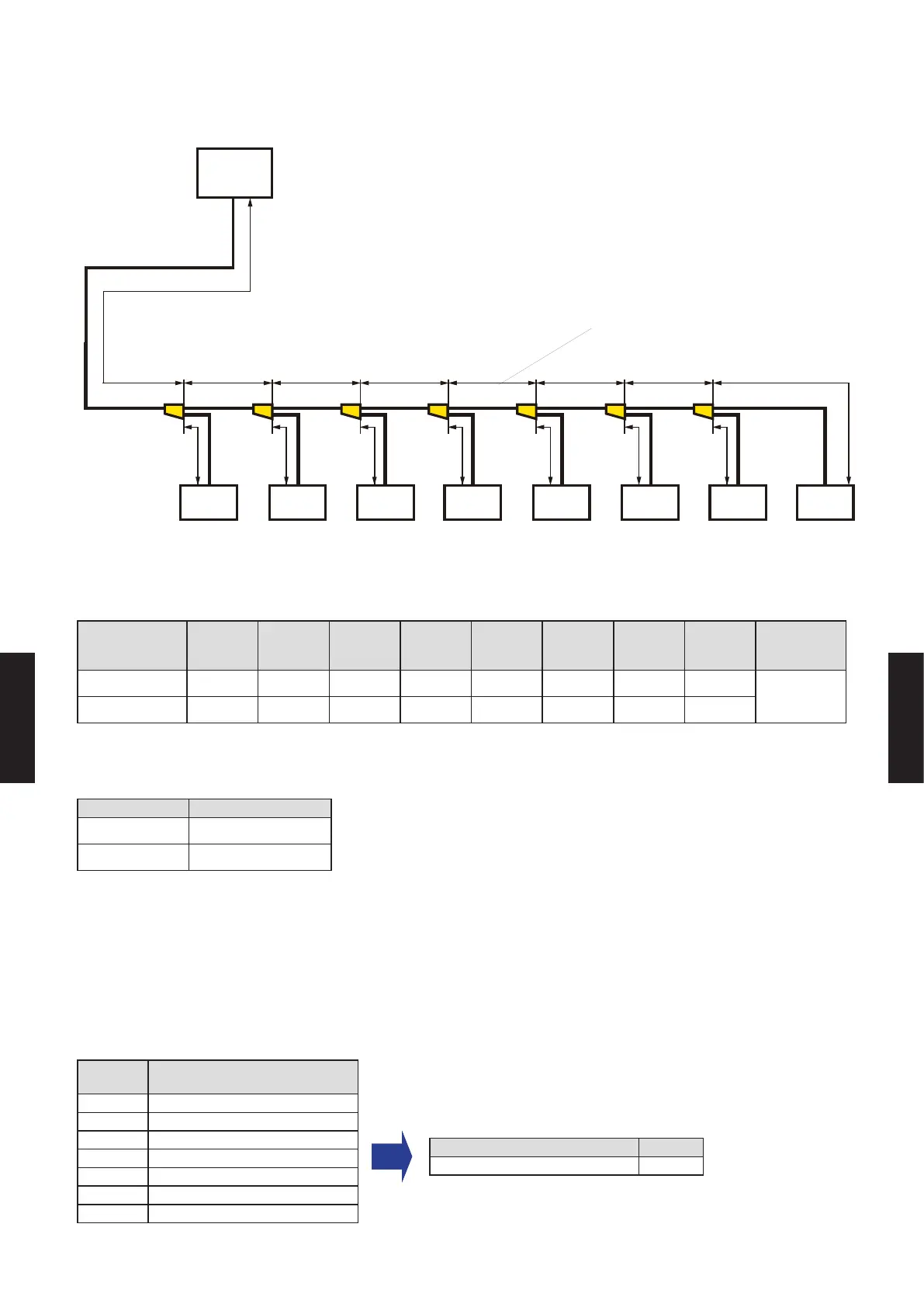

2-6. EXAMPLE OF PIPING DESIGN

REFRIGERANT SYSTEM 1

b

a

a1 b1 c1 d1 e1 f1 g1

c d e f g h

1 2 3 4 5 6 7 8

BP1 BP2 BP3 BP4 BP5 BP6 BP7

Outdoor

unit

Indoor

unit

(62.0kBtu/h)

(52.5kBtu/h)

(45.0kBtu/h)

(37. 5k Btu / h)(30.0kBtu/h)

(22.5kBtu/h)

(15.0kBtu/h)

(9.5kBtu/h) (7.5kBtu/h)

(7. 5 k Btu / h)

Indoor

unit

Indoor

unit

Indoor

unit

Indoor

unit

Indoor

unit

Indoor

unit

Total cooling capacity of indoor units

connected downwards to the pipe.

Indoor

unit

z

System conguration

(Indoor units)

1 2 3 4 5 6 7 8

Total

Capacity

(Btu/h)

Model name ARUL09 ARUL07 ARUL07 ARUL07 ARUL07 ARUL07 ARUL07 ARUL07

62,000

Capacity (Btu/h) 9,500 7, 50 0 7, 5 0 0 7,5 0 0 7,5 0 0 7,5 0 0 7,5 0 0 7, 5 0 0

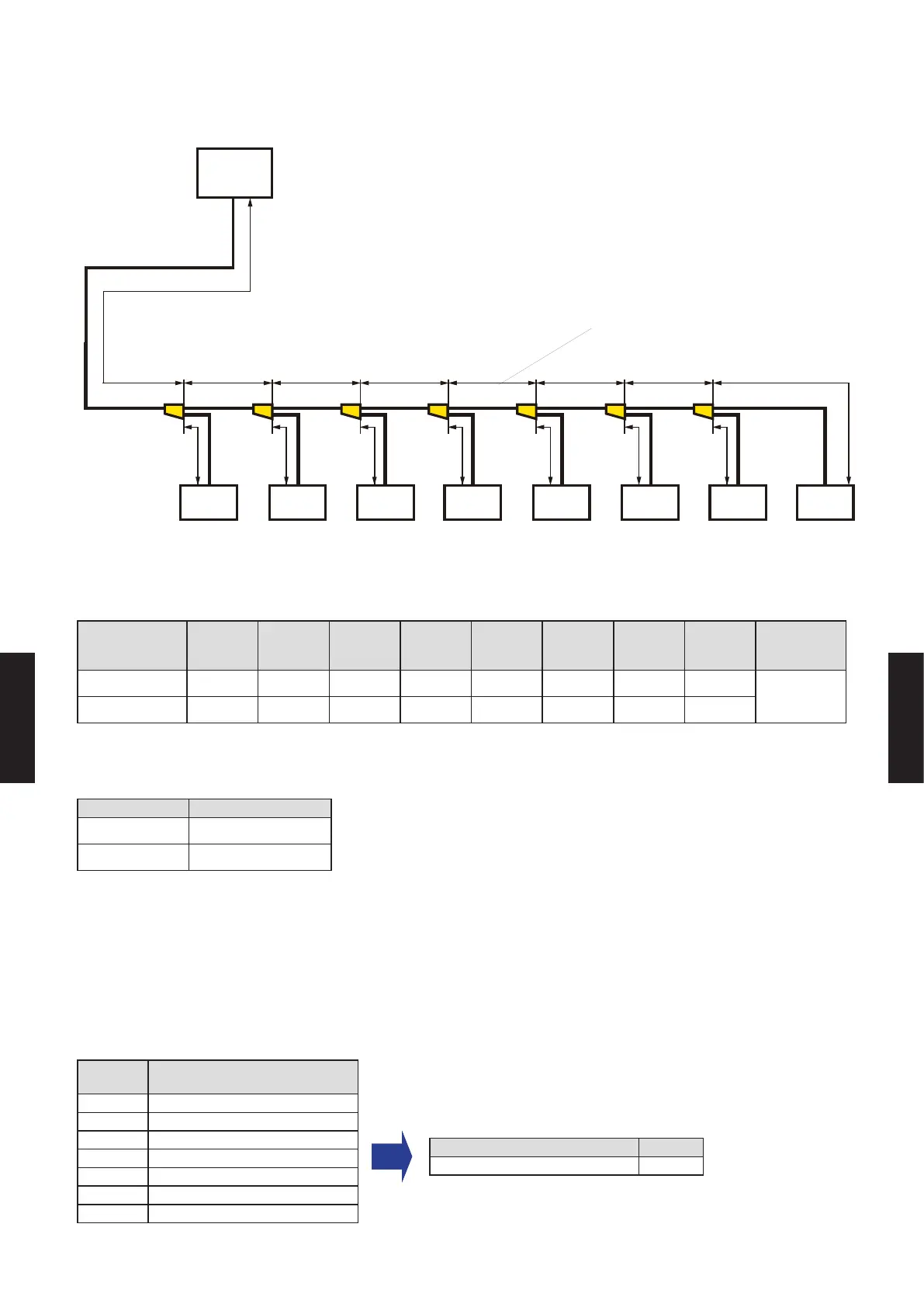

z

System conguration

(Outdoor unit)

Outdoor unit

Model name AOU60

Capacity (Btu/h) 60,000

z

Capacity ratio

(Total indoor unit capacity) / (Total outdoor unit capacity)

= (62,000) / (60,000) = 103.3% (Within 50% to 130%)

z

Selection of branch kit

Branch

point No.

Model

BP1 UTP-AX090A

BP2 UTP-AX090A

BP3 UTP-AX090A

BP4 UTP-AX090A

BP5 UTP-AX090A

BP6 UTP-AX090A

BP7 UTP-AX090A

Model Q'ty

UTP-AX090A 7

(7.5kBtu/h) (7.5kBtu/h) (7.5kBtu/h) (7.5kBtu/h) (7.5kBtu/h) (7.5kBtu/h)

- (06 - 22) -

SYSTEM

DESIGN

SYSTEM

DESIGN

Loading...

Loading...