7 Care, Maintenance and Tests

173

INTRODUCTION

This section shows you how to:

Clean and maintain the iVent

TM

201

Keep the iVent

TM

201 operable with the help of planned maintenance

Calibrate and perform diagnostic tests on the iVent

TM

201

CLEANING AND MAINTENANCE

While the iVent

TM

201 has been designed to resist damage, staining, and wear, it is

recommended to perform occasional cleaning and basic maintenance

procedures to enhance its lifecycle.

The following chart summarizes cleaning and routine maintenance procedures

and, where appropriate, time intervals.

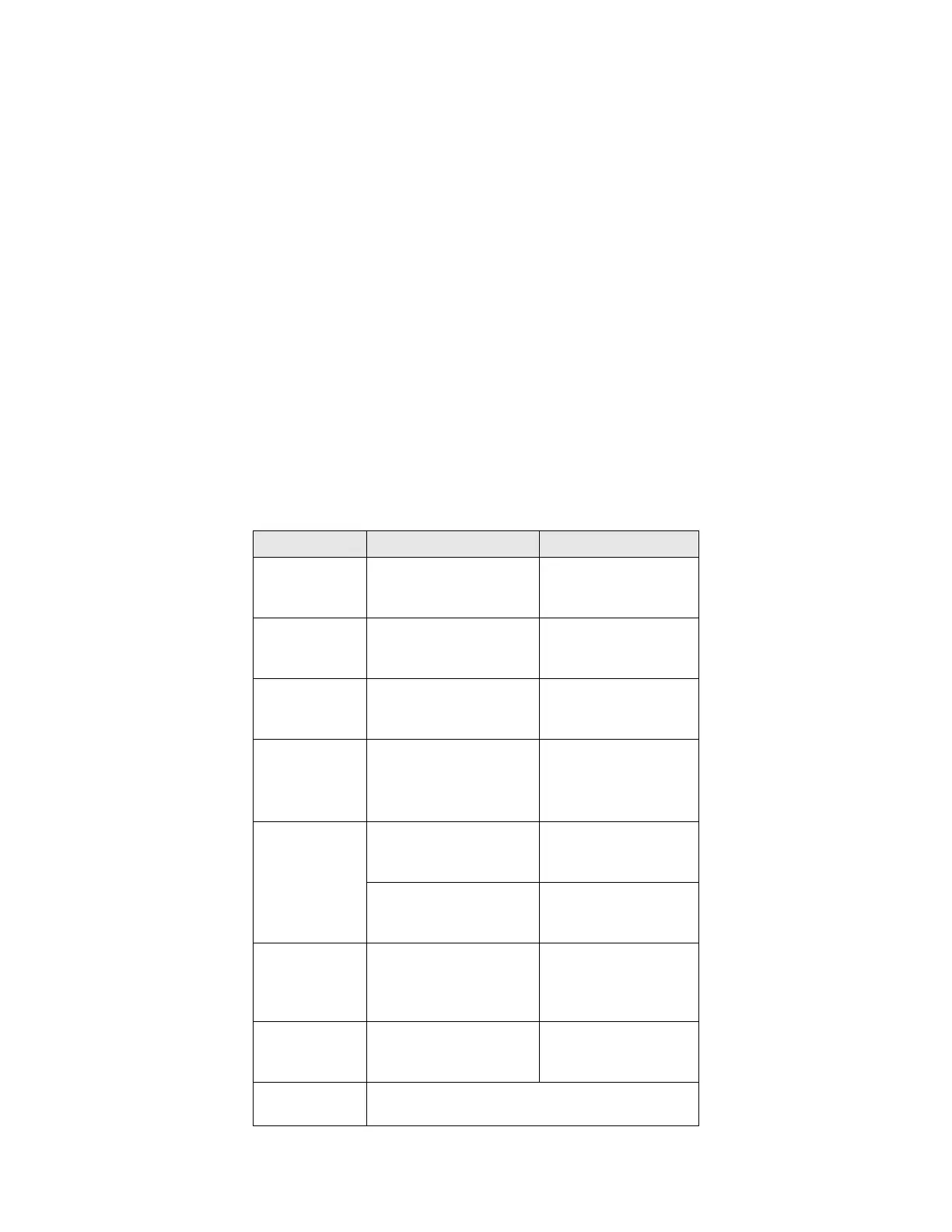

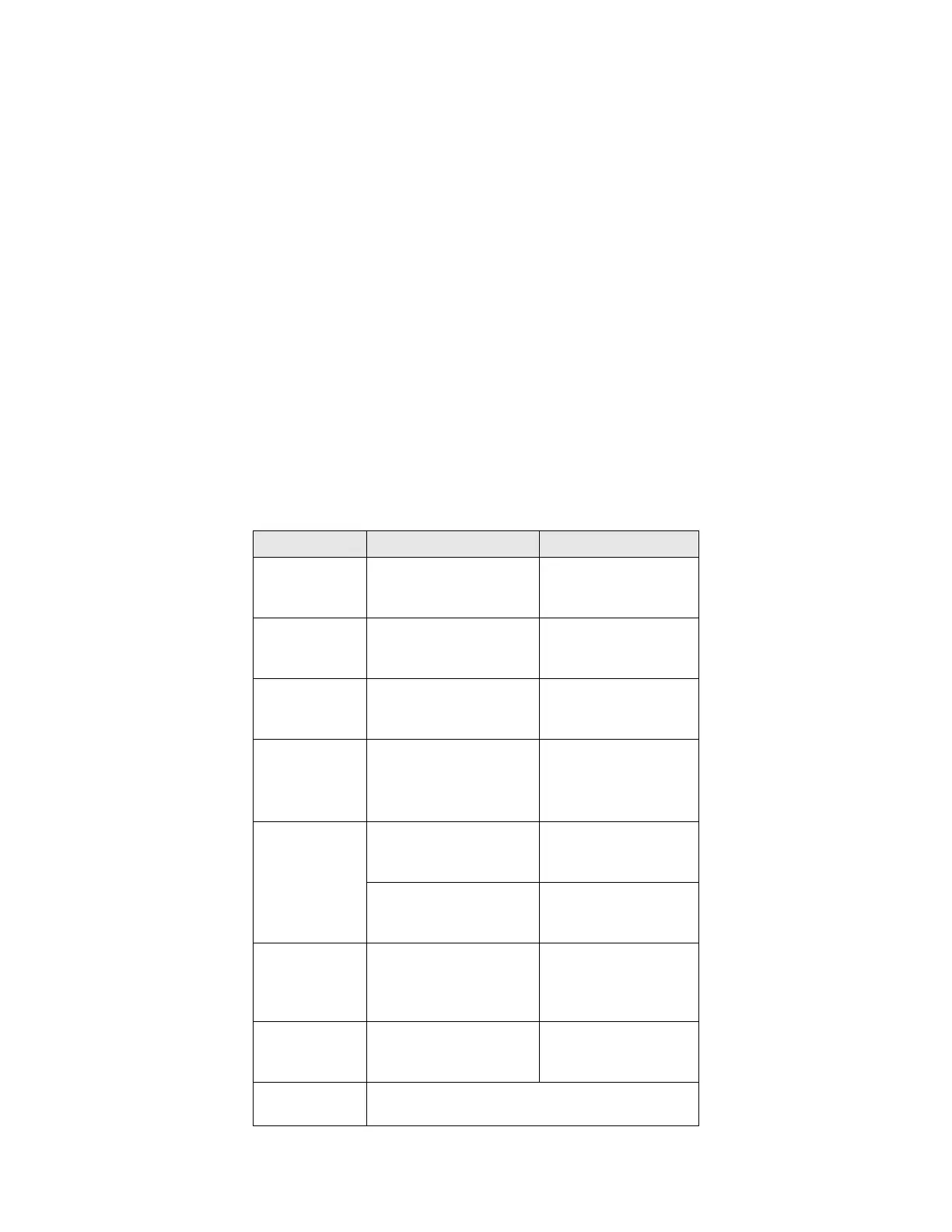

Table 12: Maintenance Procedures and Intervals

Part Procedure Comments

Ventilator Wipe exterior clean with

a damp cloth and mild

detergent.

Air Inlet Filter Replace every 500 hours

(or 1 month) of operation

or as necessary.

Do not attempt to

clean or reuse the air

inlet filter.

Cooling Vents &

Cooling Inlet

Filter

Clean every 1500 hours

(or 3 months) of use, or

as necessary.

Use vacuum device to

clean the vents and

cooling air inlet filter.

Battery Pack Recharge after every

three months of storage.

Replace every year or as

necessary.

Actual life depends on

history of use and

storage.

O

2

sensor

Calibrate every 6 months

It is good practice to

calibrate every 3

months

Replace every 2 years Perform O2 Calibration

and VVT after unit

returns from service

Pneumatic unit Replace every 15,000

hours of operation or

every 4 years, whichever

comes first.

Inlet and outlet

mufflers

Replace annually or as

necessary

Actual life depends on

history of use and

storage.

Other

accessories

Follow manufacturer instructions.

Loading...

Loading...