Chapter 6. Serial I/O, SNP & RTU Protocols

GFK-2222AD April 2018 235

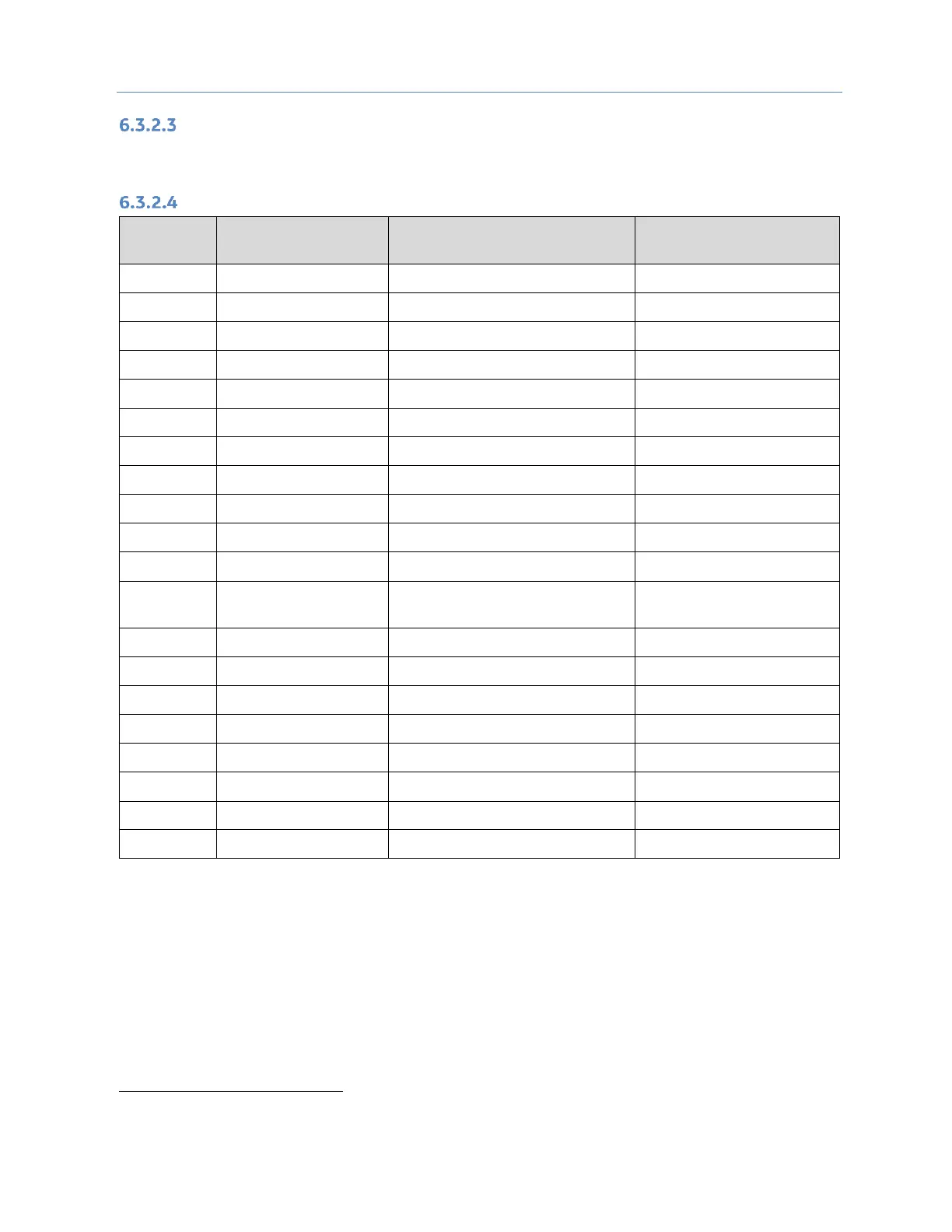

Calculating the Length of Frame

To generate the CRC-16 for any message, the message length must be known. The length for all types of

messages can be determined from the table below.

RTU Message Length

Loading...

Loading...