84 ADL300 • Quick installation guide - Specifications and connection

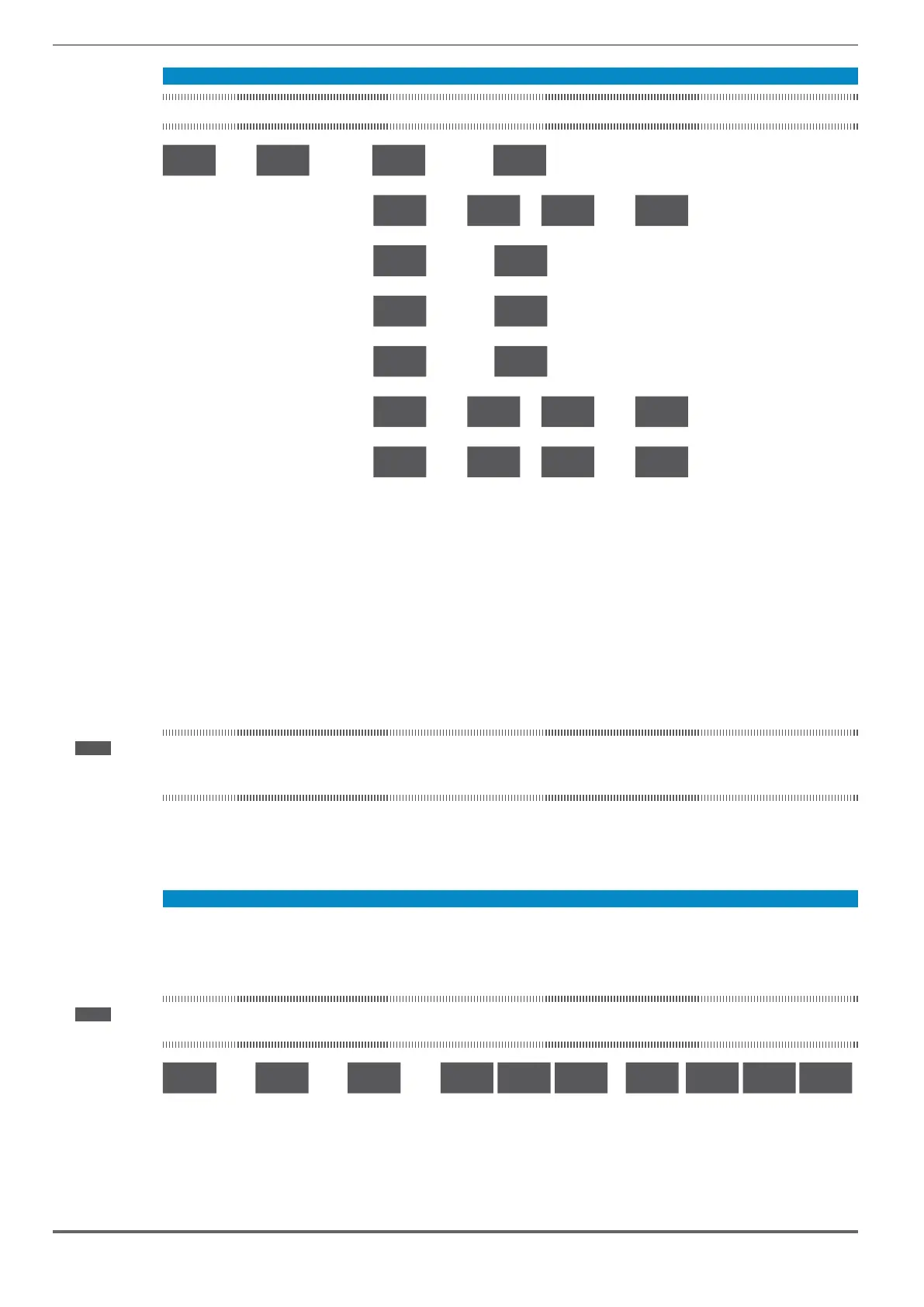

Step 2 - Setting motor parameters

Note! Def: The factory (default) setting depends on the size of the drive that is connected. These values refer to the ADL..-1055-AC

03.88.

Enter

Πo.

t8.

Enter

20.00.

Enter (x2)

04.0.0

▲

401 v

▼

399 v

Enter (x3s) Prg

20.02.

Enter

88. 11.

88.88.

Enter

88.88.

▲

11,9 A

▼

11.7 A

Enter (x3s) Prg

20.04.

Enter (x2)

14. 5.0

▲

1451 rpm

▼

1449 rpm

Enter (x3s) Prg

20.06.

Enter (x2)

00.50

▲

51 Hz

▼

49 Hz

Enter (x3s) Prg

20.08.

Enter (x2)

00 0.2

▲

3

▼

1

Enter (x3s) Prg

20. 10.

Enter

88. 85

50 8.8

Enter

50 8.8

▲

5.51 kW

▼

5.49 kW

Enter (x3s) Prg

20. 12.

Enter

88.80.

83 8.8

Enter

83 8.8

▲

0.84

▼

0.82

Enter (x3s) Prg

Set the plate data of the motor connected, according to the procedures described above.

Rated voltage [V]: the rated voltage of the motor indicated on the data plate.

Rated current [A]: motor rated current; approximately, the value should not be less than 0.3 times the rated current of the drive, output current class 1 @ 400 V

on the data plate of the drive.

Rated speed [rpm]: rated speed of the motor; this value must reect the speed of the fully loaded motor at rated frequency. If slip is indicated on the motor data

plate, set the Rated speed parameter as follows: Rated speed = Synchronous speed - Slip (e.g. for a 4-pole motor Rated speed = 1500 - 70

= 1430).

Rated frequency [Hz]: rated frequency of the motor, as shown on the data plate (asynchronous motors only).

Pole pairs: Number of motor pole pairs. The number of motor pole pairs is calculated using the plate data and the following formula:

P = 60 [s] x f [Hz] / nN [rpm]

Where: P = motor pole pairs, f = motor rated frequency (e.g. 50); nN = motor rated speed (e.g. 1450)

Rated power [kW]: Motor rated power; for a motor data plate with an HP power value, set the rated power kW = 0.736 x the motor power HP value.

Rated power factor: Leave the default rated power factor if the data are not available on the data plate.

Note! When data entry is complete the Take parameters command is executed automatically (menu 14 MOTOR DATA, PAR: 2020). The motor data entered during

the STARTUP WIZARD procedure are saved in a RAM memory to enable the drive to perform the necessary calculations.

These data are lost if the device is switched off. To save the motor data follow the procedure described in step 9.

At the end of the procedure proceed to step 3. Press the Prg and keys.

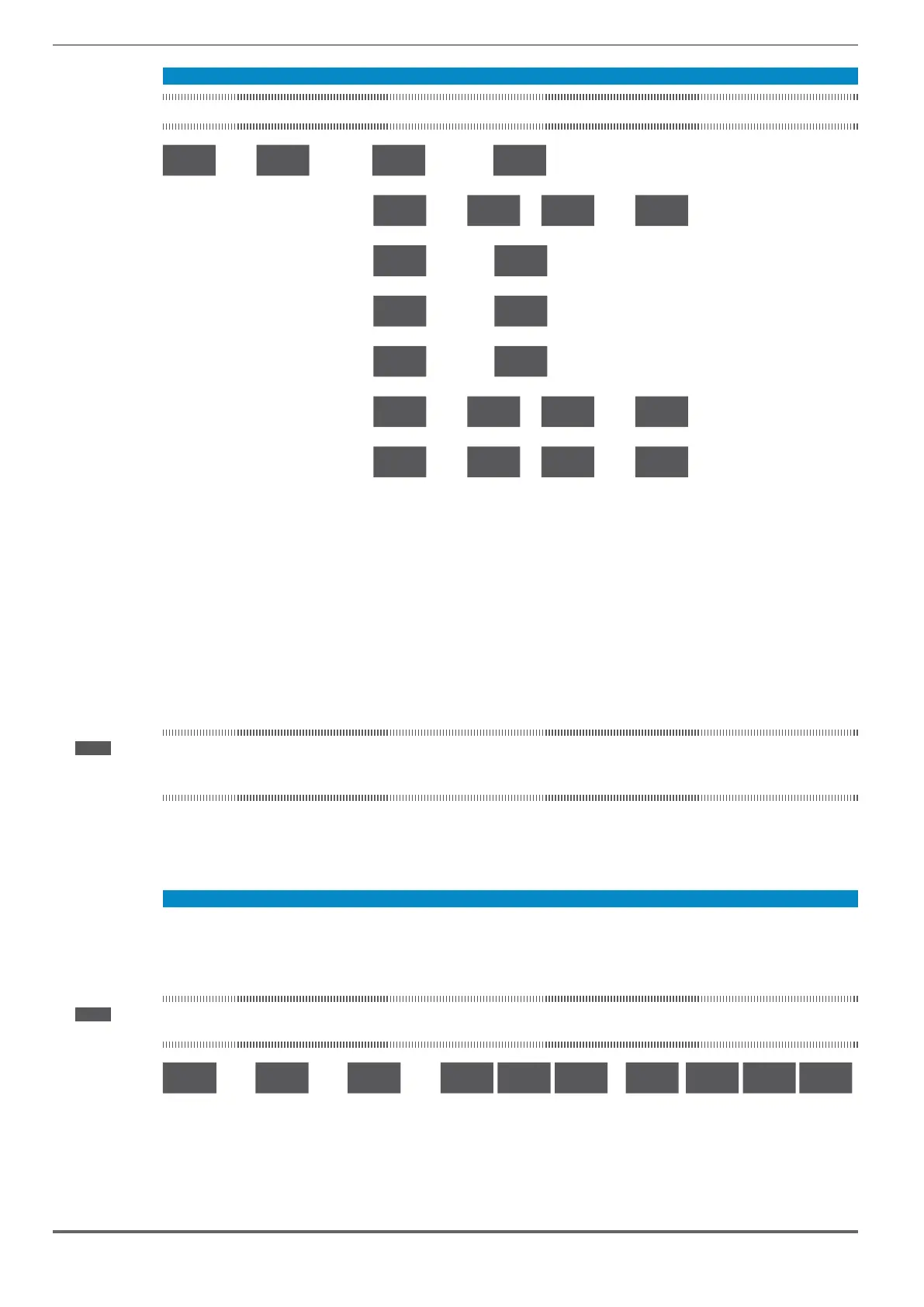

Step 3 - Autotune with motor at stand-still or coupled to the load

The drive carries out the motor autotune procedure (real measurement of motor parameters).

There are two self-tuning modes: Reduced (default) and Extended, which can be selected using parameter 2026 Au-

totune mode. The reduced procedure is fast and recommended in most cases. The extended procedure can be used

to achieve maximum efciency, but may take several minutes.

Note! If this operation generates an error message (e.g. Error code 1), check the connections of the power and control circuits (see step 1 - Connections), check the

motor data settings (see step 2 - Setting motor parameters) and then repeat the guided Autotune procedure.

St.

iL

.

Enter

20.24.

Enter

8

E.

nt

.

Enter

do.nE.

C8 En.

88.8.0

...

8

6 5.ˉ

o8 En.

81.00.

do.nE.

(1) (2) (3) (4) (5)

(1) Press the Enter key to proceed to the autotune procedure.

(2) Press the Enter key to start the autotune procedure.

(3) Enable the drive by connecting terminal 9 on the I/O card (Enable) to terminal 12 (+24 V). To abort this operation,

press the Prg key.

Loading...

Loading...