Maintenance Manual April 2018

Programmed Maintenance Procedures

138 S

®

Booms • Z

®

Booms Part No. 1268489GT

P0-10

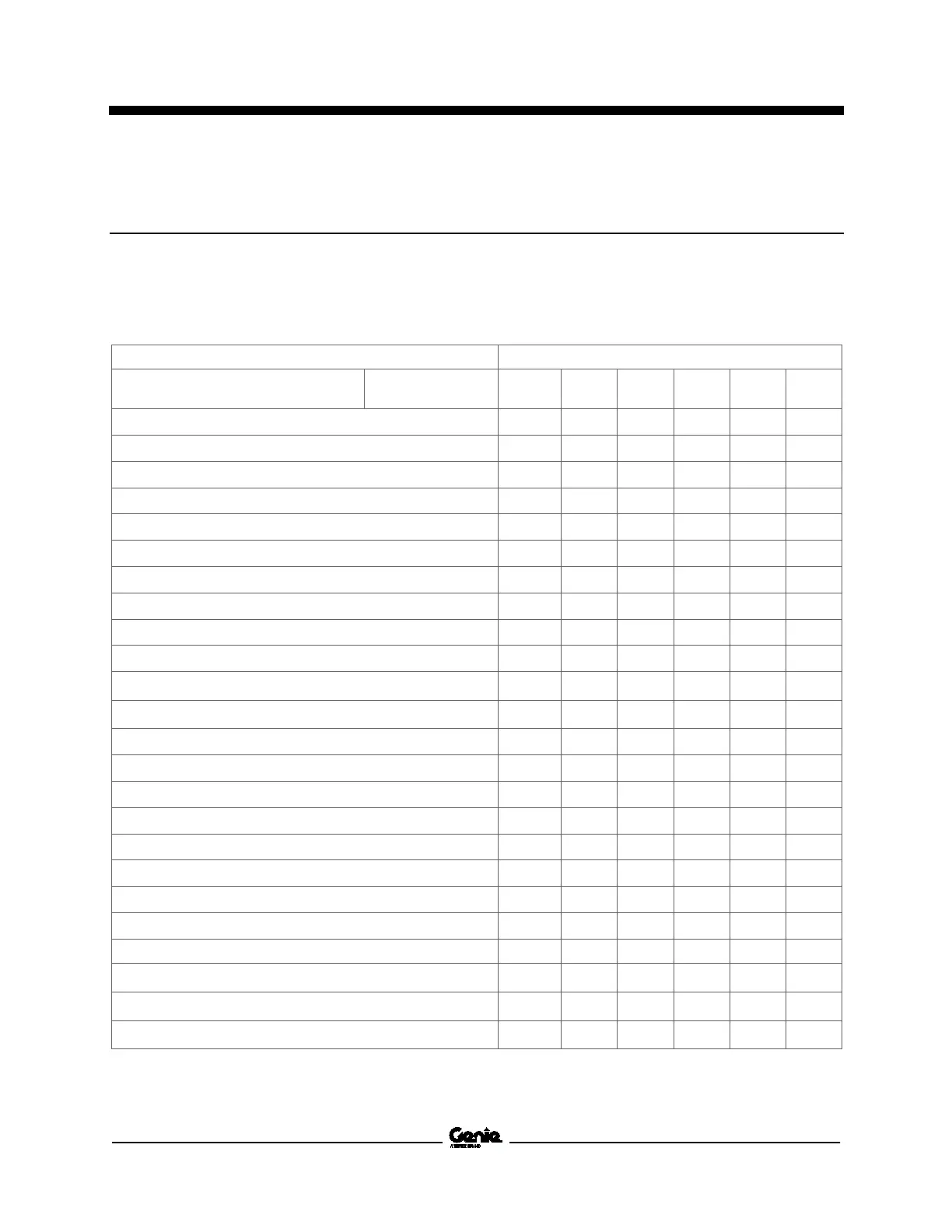

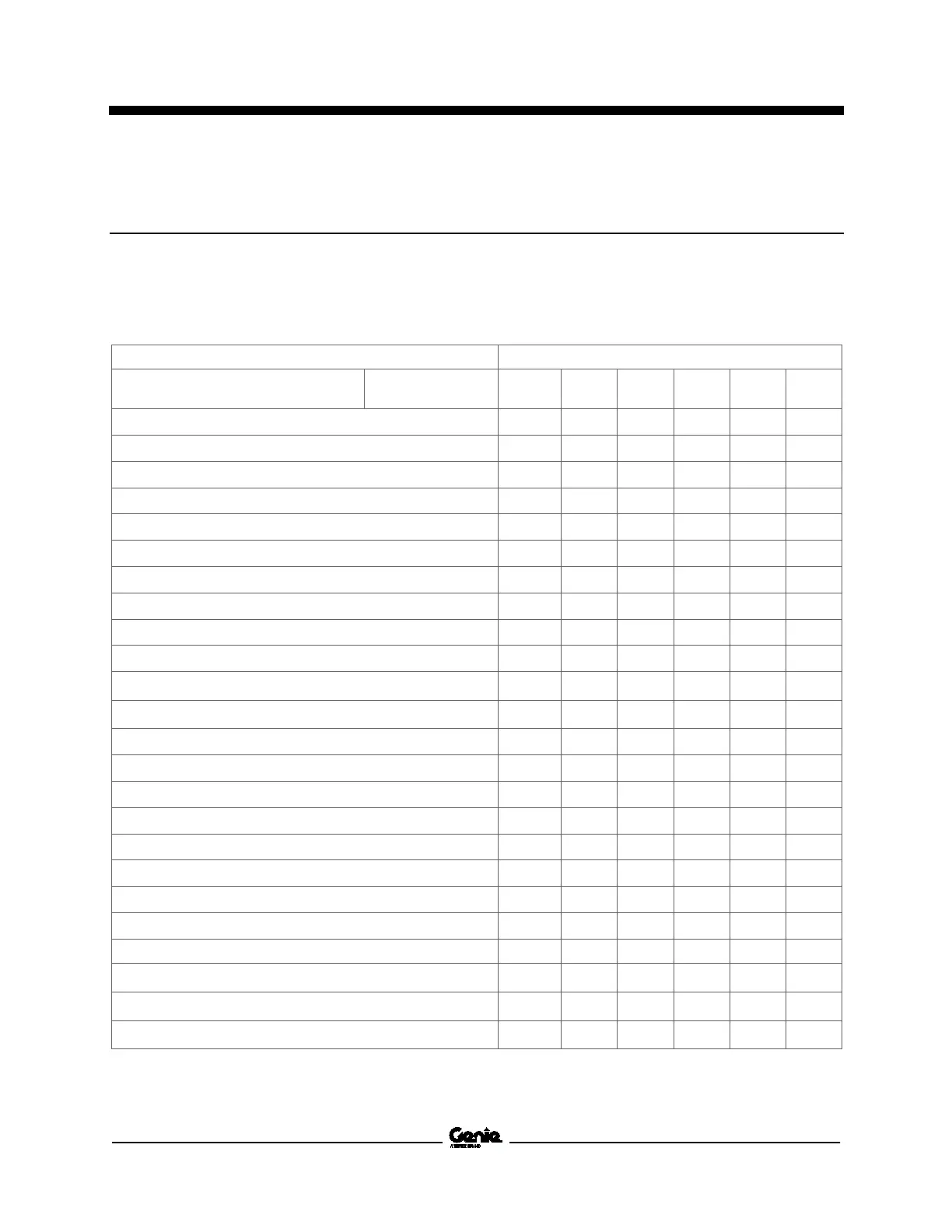

GM .998L Engine Maintenance – Under 1000 Hours

Additional engine maintenance is required. Refer to the Programmed Maintenance Inspection Report for

the specific intervals that apply.

Required maintenance procedures and additional engine information are available in the manufacturer's

manuals. Refer to Specifications, Engine Operator and Maintenance Manuals.

Procedure

Not required

Daily 100 150 200 400 800

Coolant level - check

∅ ∅ ∅ ∅ ∅

Oil level - check

∅ ∅ ∅ ∅ ∅

Oil, fuel and coolant systems - check for leaks

∅ ∅ ∅ ∅ ∅

Fan belt tension and damage - check

∅

∅ ∅ ∅ ∅

Radiator hoses and clamps - check

∅

∅ ∅ ∅ ∅

Intake manifold - check for vacuum leaks

∅

∅ ∅ ∅ ∅

LPG system - check for leaks

∅

∅ ∅ ∅ ∅

Radiator – clean • Radiator hoses and clamps - check

∅

∅ ∅ ∅ ∅

Engine oil and filter – replace

∅ ∅

∅ ∅ ∅

LPG Vaporizer - drain/clean

∅ ∅

∅ ∅ ∅

PCV valve - check

∅ ∅ ∅

∅ ∅

Air cleaner element - clean/replace

∅ ∅ ∅

∅ ∅

Timing belt - check

∅ ∅ ∅

∅ ∅

Electrical wiring - check for chafing or damage

∅ ∅ ∅ ∅

∅

Vacuum lines and fittings - check

∅ ∅ ∅ ∅

∅

Fuel filter - replace

∅ ∅ ∅ ∅

∅

Fuel lines and clamps - check for leaks

∅ ∅ ∅ ∅

∅

Air intake system - inspect for leaks

∅ ∅ ∅ ∅

∅

Cylinder head bolts - torque (40.5 ft-lbs / 55 Nm)

∅ ∅ ∅ ∅

∅

Valve clearance - check/adjust

∅ ∅ ∅ ∅

∅

PCV valve - replace

∅ ∅ ∅ ∅ ∅

Cooling system coolant - replace

∅ ∅ ∅ ∅ ∅

Spark plugs - replace

∅ ∅ ∅ ∅ ∅

Spark plug wires - check/replace

∅ ∅ ∅ ∅ ∅

Loading...

Loading...