◐ Test Lamination

1. When temp. on laminating roller is reached to setting temp., test lamination is required to check setting status & laminating quality.

Press "RUN" to make roller engage and lamination is processed.

Feeding gap & Feeding error has to be checked for the 1st 3~4 sheets feeding.

For test lamination, the lower speed (3~5m/min) is recommended. Then, its test result is good, increase its speed.

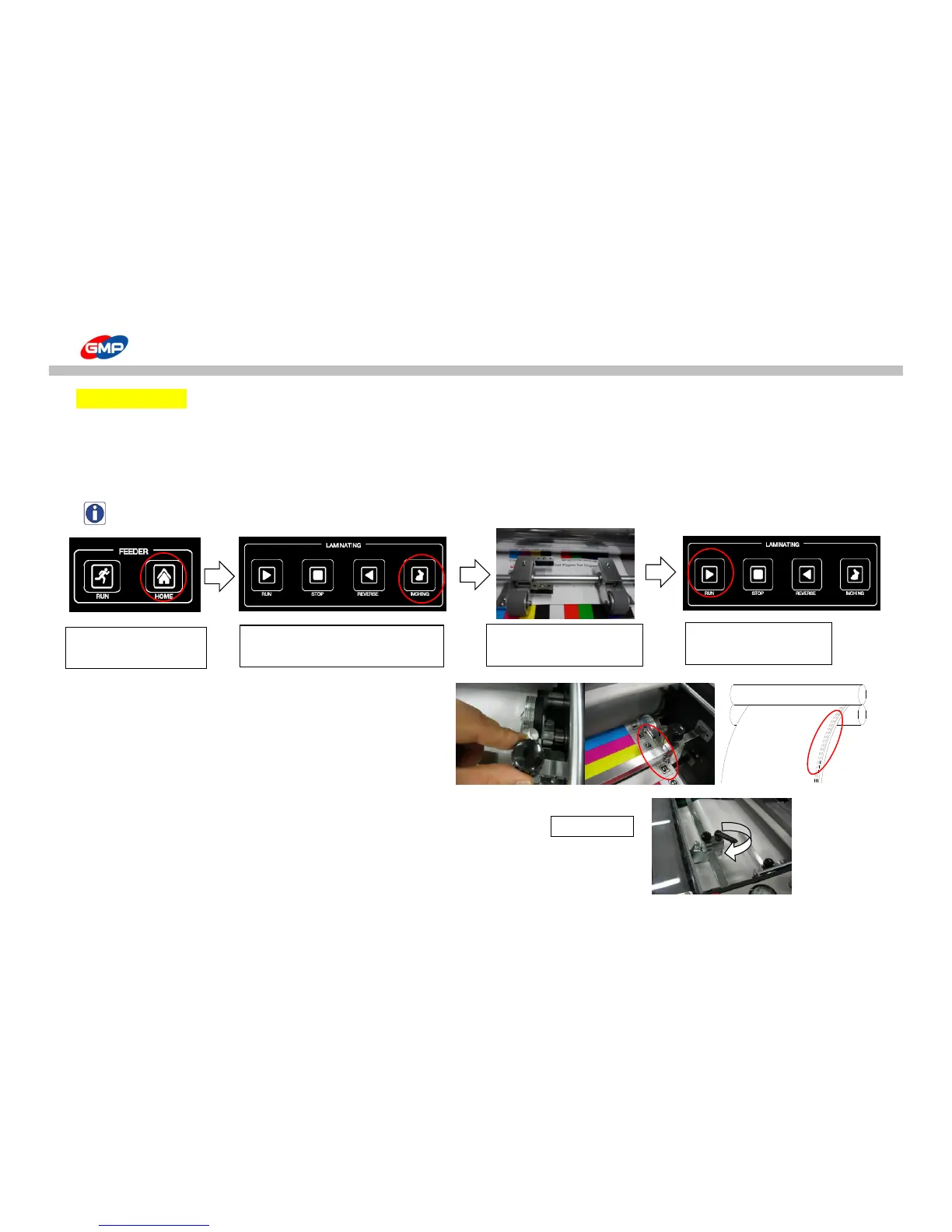

NOTE : How to load substrate after release from E-Stop status. (ex: EMERGENCY, Safety Cover is opened.)

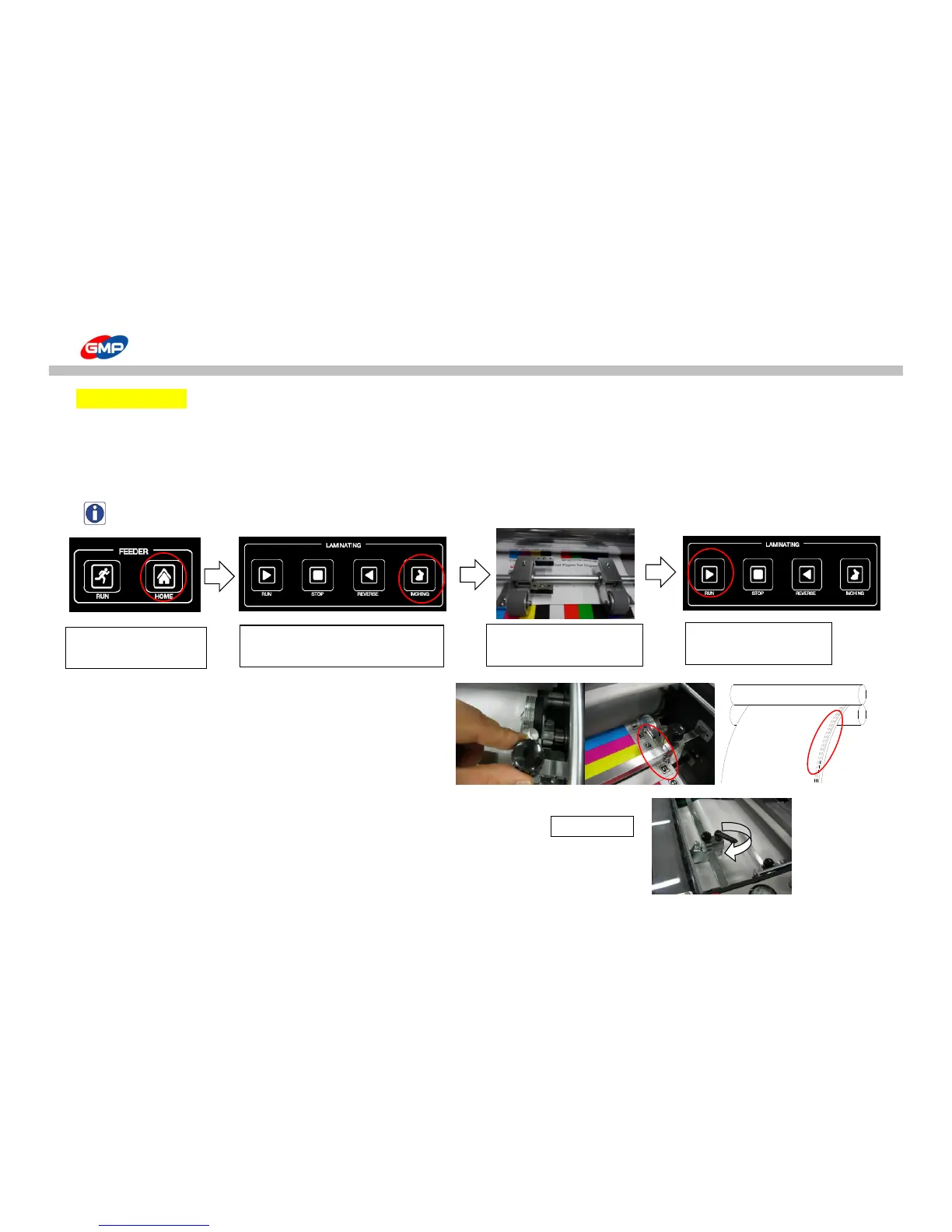

2. If there is no problem for substrate feeding, set up the perforator.

Position the perforator at 1~3mm from film edge.

If the perforator would be more inside of the above position,

this could be a cause of quality trouble & cutting error.

Pressure on film to make holes clearly.

3. Press "BURSTING" on "MAIN" screen to activate Burst "ON" status.

Rotating Bursting roller is moved up/down to cut the laminated results.

If a cutting quality is not good, install the skewing wheel as the picture <2_2>.

① Feeder at Origin Point.

② Move sheets at Feeding Wheel to

Laminating Roller in Job Mode.

③ Attach the substrate end to

the film on roller.

Loading...

Loading...