Cutting Area Bursting Roller is not 1. Defective Bursting Roller Motor or Chain -> Contact to a supplier.

operated. 2. Fuse blows -> Replace it with 250V/8A that is packed with machine.

3. Defective Air Compressor -> Contact to a supplier.

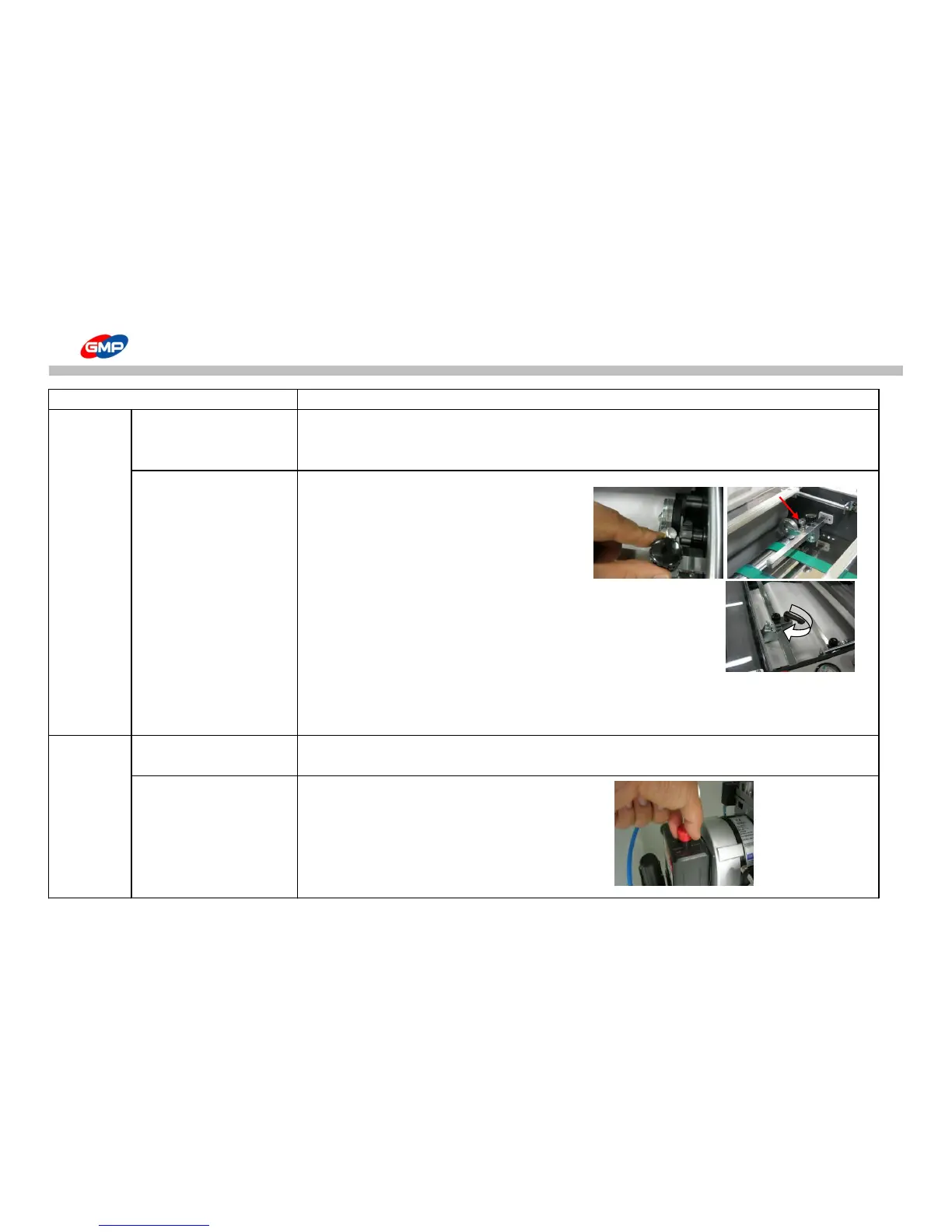

Cutting is not good 1. Perforator is at wrong position.

-> Place it at 1~3mm from film edge.

2. Perforator has lower pressure.

-> Increase pressure with pressure adjustment bolt.

3. Setting for skewing wheel is wrong.

-> Install the wheel to make sheet curve.

The wheel skews a lot the laminated results, the results are damaged

or it skews reversely, it makes cutting error.

4. "NYLONEX(Nylon base)","PERFEX(PET base)" films are used.

-> Characteristics of the above materials make cut hard. Increase angle for the skewing wheel.

-> Press "BURST SPEED" in "SET" mode to increase bursting roller rotating speed.

5. Use In-Line Perforator.

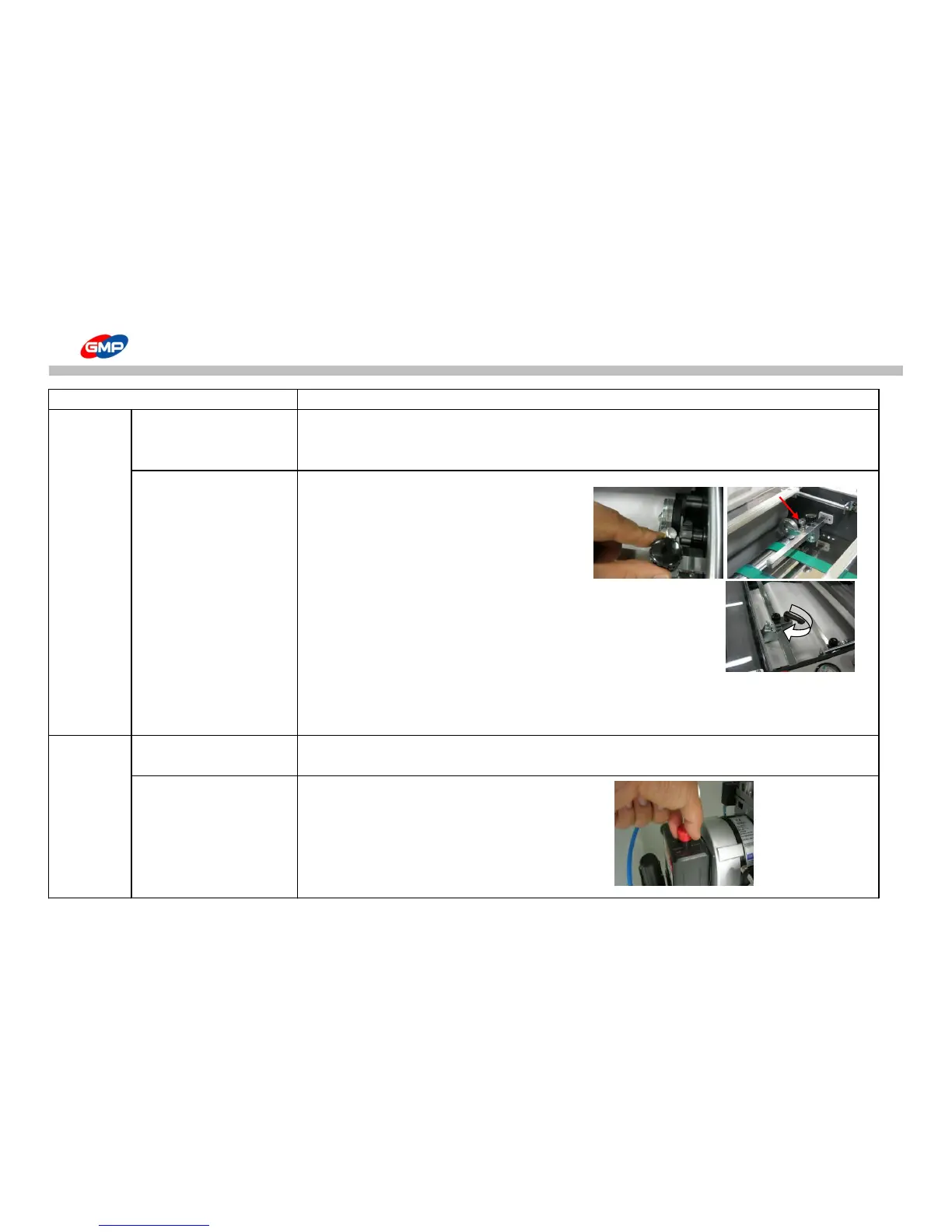

Others Machine is not turned on. 1. If the power plug is incorrect. -> Insert the plug into the outlet exactly.

2. Fuse blows -> Replace it with 250V/12.5A fuse

Loading...

Loading...