Published 08-25-09, Control # 077-04 2-73

RT9130E SERVICE MANUAL HYDRAULIC SYSTEM

4. Install the low temperature o-ring and backup rings onto

the outside of the head.

5. Install the cylinder head onto the cylinder rod.

6. Install the spacer onto the cylinder rod.

7. Install the o-ring and backup rings into the inside of the

piston.

NOTE: Use a new self-locking soft-tip setscrew.

8. Screw the piston onto cylinder rod and secure with a

new setscrew.

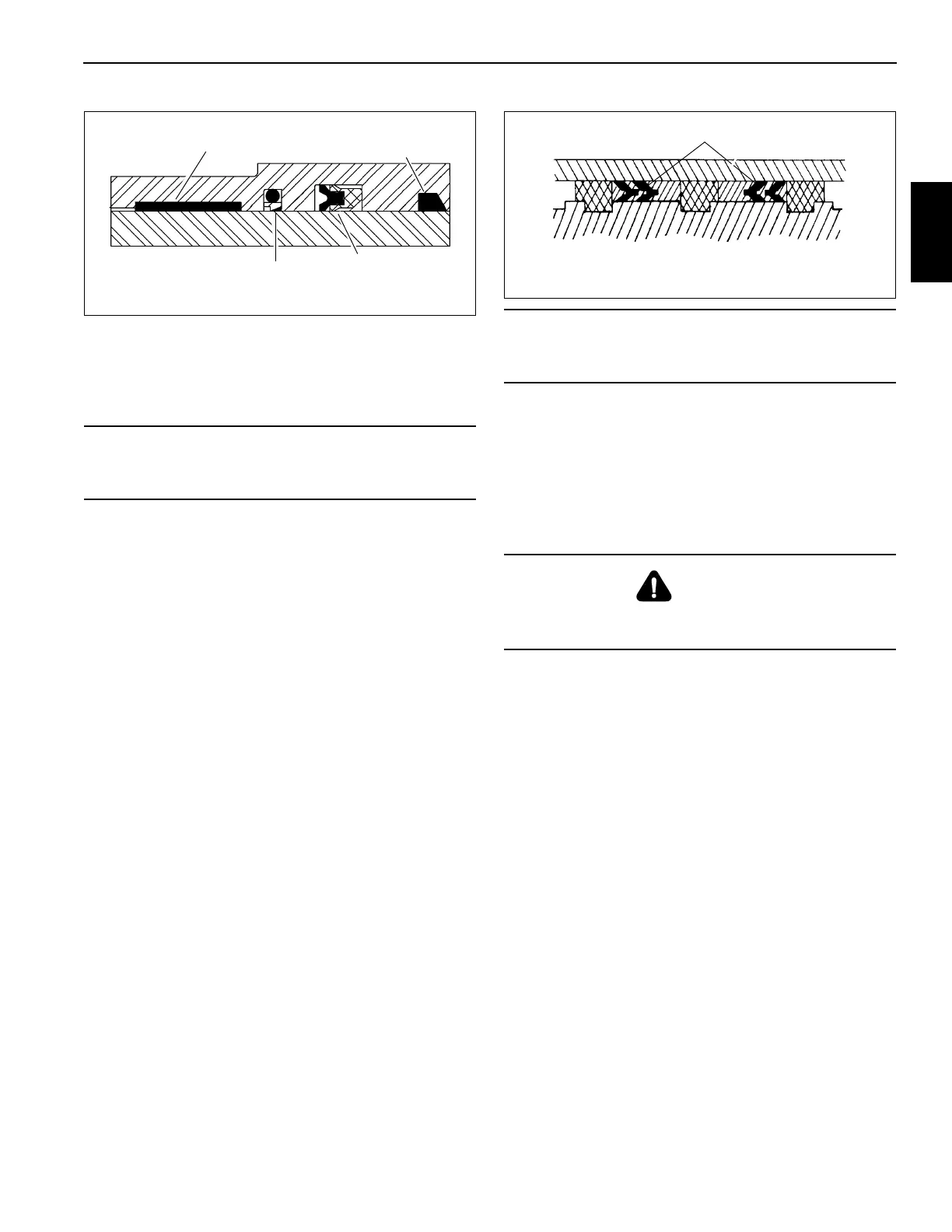

9. Install the guide lock rings and hydrolock seals onto the

outside of the piston. Refer to (Figure 2-43).

10. Clean all oil from the threads of the cylinder head and

apply Loctite #290 to the threads.

11. Lubricate the piston seals and cylinder head o-ring with

clean hydraulic oil and install the rod assembly into the

cylinder barrel with a slight twisting motion.

12. Using a chain wrench, secure the cylinder head to the

cylinder barrel.

13. Pressurize and cycle the cylinder with hydraulic oil

pressure. Test the cylinder at 36197.4 kPa/36.1 bar

(5250 psi) retracted (rod side pressure) or 25855.3 kPa/

25.8 bar (3750 psi) extended (piston side pressure).

Check for proper operation and any leakage. Make

repairs as needed.

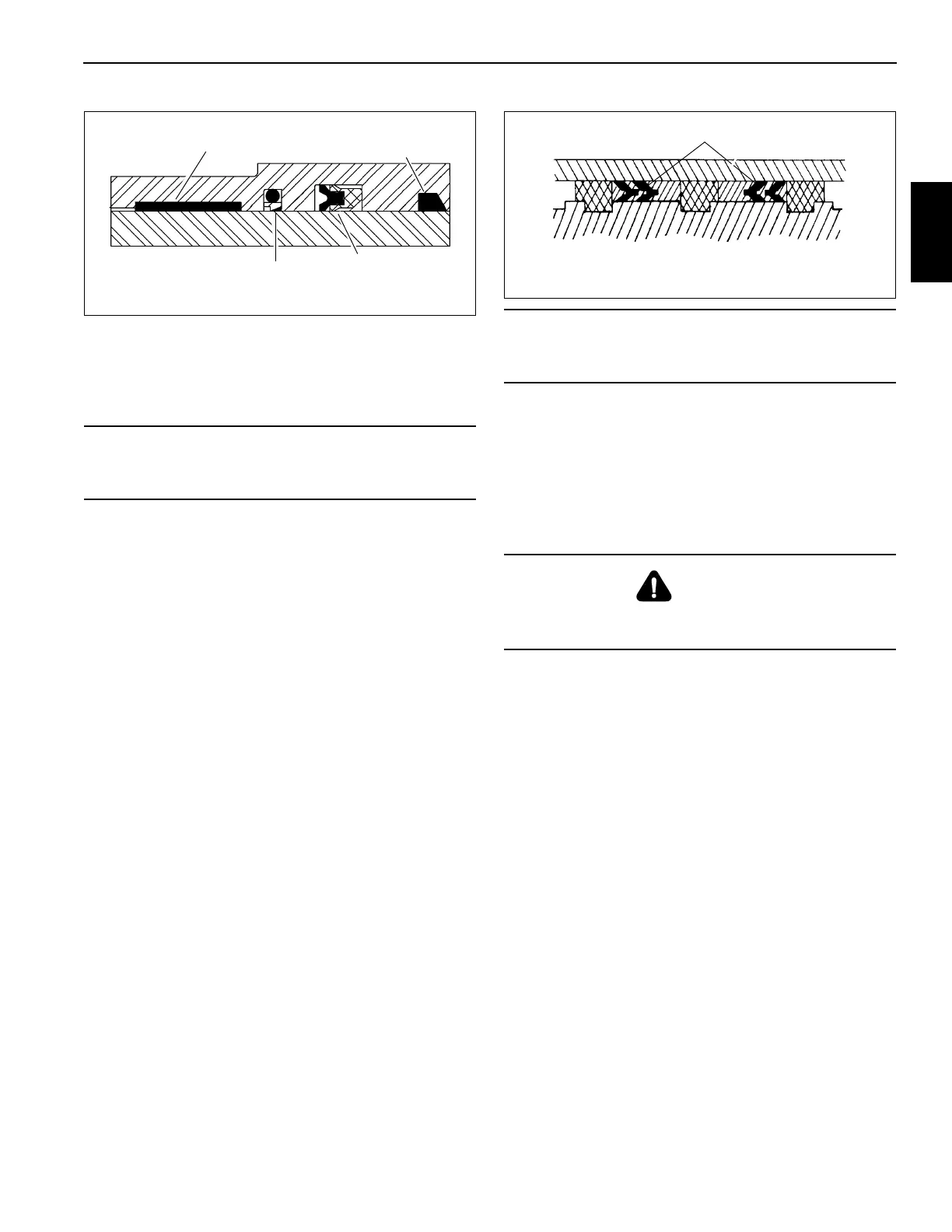

CAUTION

Improper seal installation could cause faulty cylinder

operation.

Wiper Ring

Deep Z Rod Seal

Buffer Seal

Wear Ring

FIGURE 2-42

CAUTION

Do not scratch the grooved and gland surfaces or

damage the seals and o-rings.

DANGER

Do not use air pressure to cycle the cylinder. Use only

controlled hydraulic pressure.

Hydrolock Piston Seals

FIGURE 2-43

Loading...

Loading...