Published 08-25-09, Control # 077-04 1-15

RT9130E SERVICE MANUAL INTRODUCTION

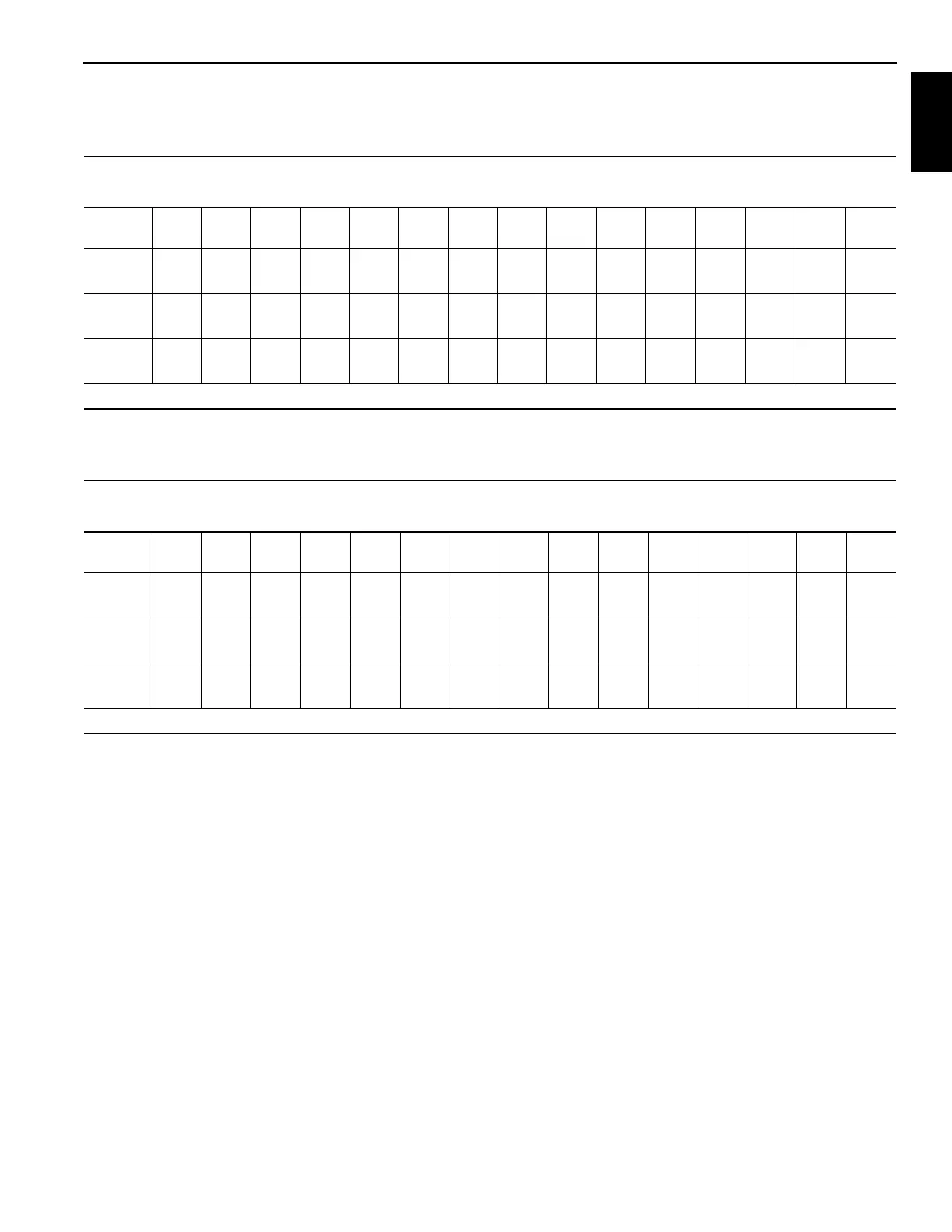

Table 1-4

Torque Values For Metric Fasteners With No Special Lubrication - Coarse Threads

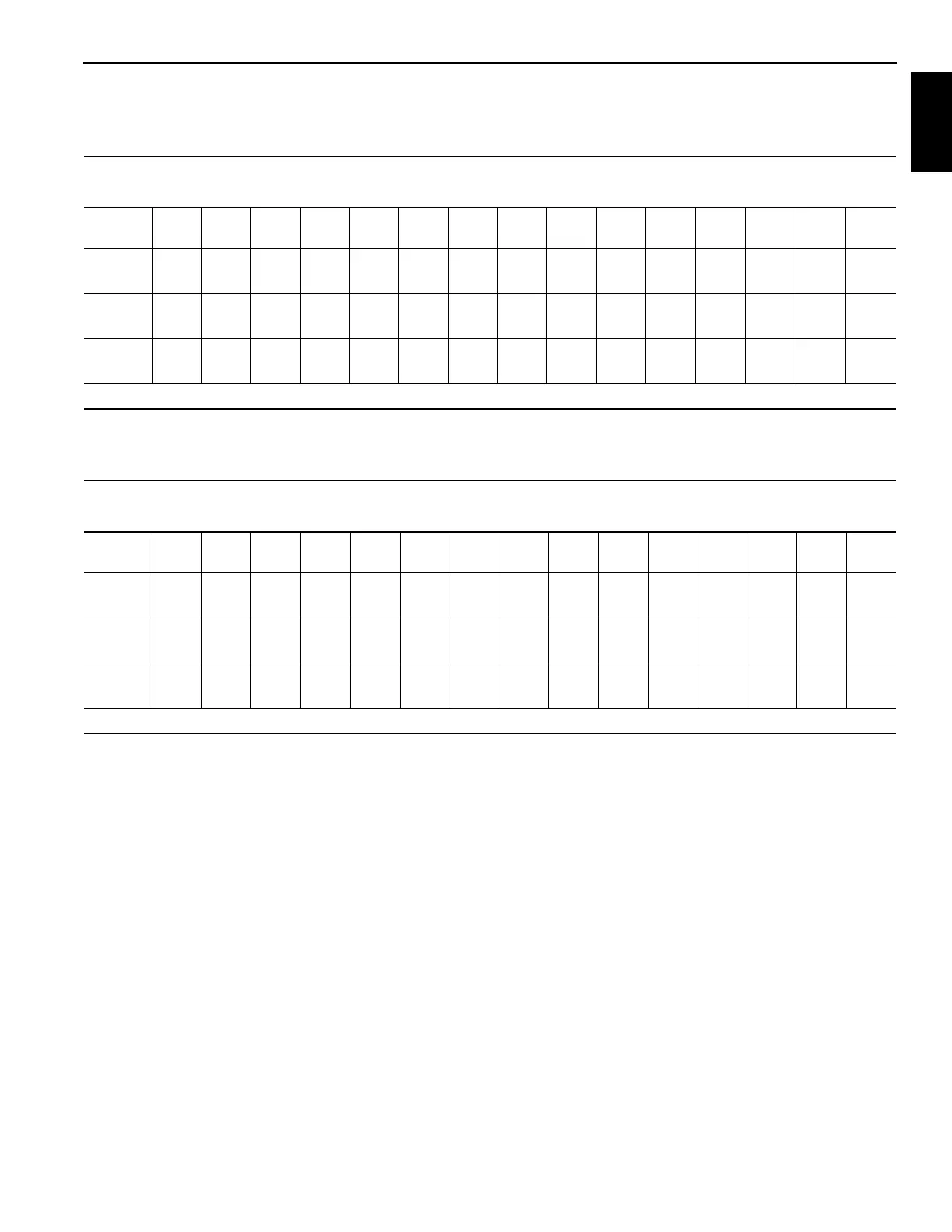

Table 1-5

Torque Values For Metric Fasteners With No Special Lubrication - Coarse Threads

WIRE ROPE

General

The following information is a compendium of information

from various wire rope manufacturers and includes

inspection, replacement, and maintenance guidelines for

wire rope as established by ANSI/ASME B30.5, federal

regulations, and Manitowoc. The inspection interval shall be

determined by a qualified person and shall be based on such

factors as expected rope life as determined by experience on

the particular installation or similar installations, severity of

environment, percentage of capacity lifts, frequency rates of

operation, and exposure to shock loads. Periodic

Inspections need not be at equal calendar intervals and

should be performed at shorter time intervals as the wire

rope approaches the end of its useful life. A periodic

inspection shall be performed at least once a year. The

following provides inspection and maintenance procedures

for wire ropes used on Grove products (e.g. wire rope used

as load lines [hoisting cables], boom extension and

retraction cables, pendant cables, tow winch cables, and

hook block tie down cables).

Environmental Conditions

The life expectancy of wire rope may vary due to the degree

of environmental hostility and other conditions to which these

mechanical devices are subjected. Variation in temperature,

continuous excessive moisture levels, exposure to corrosive

chemicals or vapors or subjecting the wire rope to abrasive

material may shorten normal wire rope life. Frequent/

periodic inspections and maintenance of your wire rope is

recommended for preventing premature wear and to insure

long-term satisfactory performance.

Dynamic Shock Loads

Subjecting wire rope to abnormal loads beyond the

endurance limit will shorten the wire ropes, life expectancy.

Examples of this type of loading are listed below.

Bolt Diameter - Metric

TORQUE VALUES (Nm)

Grade

M4

0.157

M5

0.197

M6

0.236

M7

0.276

M8

0.315

M10

0.394

M12

0.472

M14

0.551

M16

0.630

M18

0.709

M20

0.787

M22

0.866

M24

0.945

M27

1.06

M30

1.18

8.8

3.1

2.8

6.5

5.9

11

10

19

17

27

25

53

49

93

85

148

136

230

212

391

294

447

413

608

562

774

714

1134

1046

1538

1420

10.9

4.5

4.1

9.2

8.5

16

14

26

24

38

35

75

69

130

120

212

195

322

298

455

418

629

581

856

790

1089

1005

1591

1469

2163

1997

12.9

5.4

4.9

11

10

19

17

31

28

45

42

89

83

156

144

248

228

387

357

532

490

756

698

1029

949

1306

1206

1910

1763

2595

2395

NOTE 1: Torque values for fine threads are 8% higher.

Bolt Diameter - Metric

TORQUE VALUES (Pounds - Foot)

Grade

M4

0.157

M5

0.197

M6

0.236

M7

0.276

M8

0.315

M10

0.394

M12

0.472

M14

0.551

M16

0.630

M18

0.709

M20

0.787

M22

0.866

M24

0.945

M27

1.06

M30

1.18

8.8

2.3

2.1

4.8

4.3

8.1

7.4

14.0

12.5

20

18

39

36

69

63

109

100

170

156

235

217

329

304

448

414

548

526

836

771

1134

1047

10.9

3.3

3.0

6.8

6.3

11.8

10.3

19.0

17.6

29

26

55

51

96

88

156

144

237

220

335

308

464

428

631

582

803

741

1173

1083

1594

1472

12.9

4.0

3.6

8.1

7.4

14.0

12.5

23.0

20.6

33

31

66

61

115

106

183

168

285

263

392

361

557

514

758

699

963

889

1408

1299

1913

1765

NOTE 1: Torque values for fine threads are 8% higher.

Loading...

Loading...