Published 08-25-09, Control # 077-04 4-23

RT9130E SERVICE MANUAL BOOM

TELESCOPE CIRCUIT

Description

The boom telescope circuit consists of the telescope

hydraulic remote controller, telescope directional control

valve, holding valve, hose reel, and the upper and lower

telescope cylinders.

The telescope control valve is the closed spool type and is

described under VALVES in Section 2.

Refer to VALVES in Section 2 for a complete description of

the hydraulic remote controller.

The boom telescope system has a lower and an upper

telescope cylinder. The lower telescope cylinder is a two

stage cylinder. The first stage is 7.50 inch bore and the

second stage is a 9.25 inch bore. The upper telescope

cylinder has a 7.50 inch bore. Foreign material is prevented

from entering the cylinder by a wiper seal during rod

retraction. O-ring seals prevent internal and external

leakage. Refer to CYLINDERS in Section 2 - HYDRAULIC

SYSTEM for a complete description of the telescope

cylinder.

A holding valve is threaded into a port block on the rod end of

the upper telescope cylinder and the first stage rod end on

the lower telescope cylinder. The holding valve for the

second stage of the lower telescope cylinder is mounted into

the port block on the barrel end of the second stage barrel.

The holding valves function during the retraction, extension,

or holding operation. When holding the boom section at a

given length, oil is trapped in the cylinder by the holding

valve. Refer to VALVES in Section 2 for a complete

description of the holding valve.

Theory Of Operation

Flow from the pump travels to the telescope directional

control valve. Movement of the foot pedal for telescope

functions from neutral sends a pilot pressure signal to the

directional control valve to shift the spool in the directional

control valve. This aligns the appropriate passages in the

control valve to route oil to the telescope cylinders.

For more information, refer to BOOM - THEORY OF

OPERATION in this Section.

Maintenance

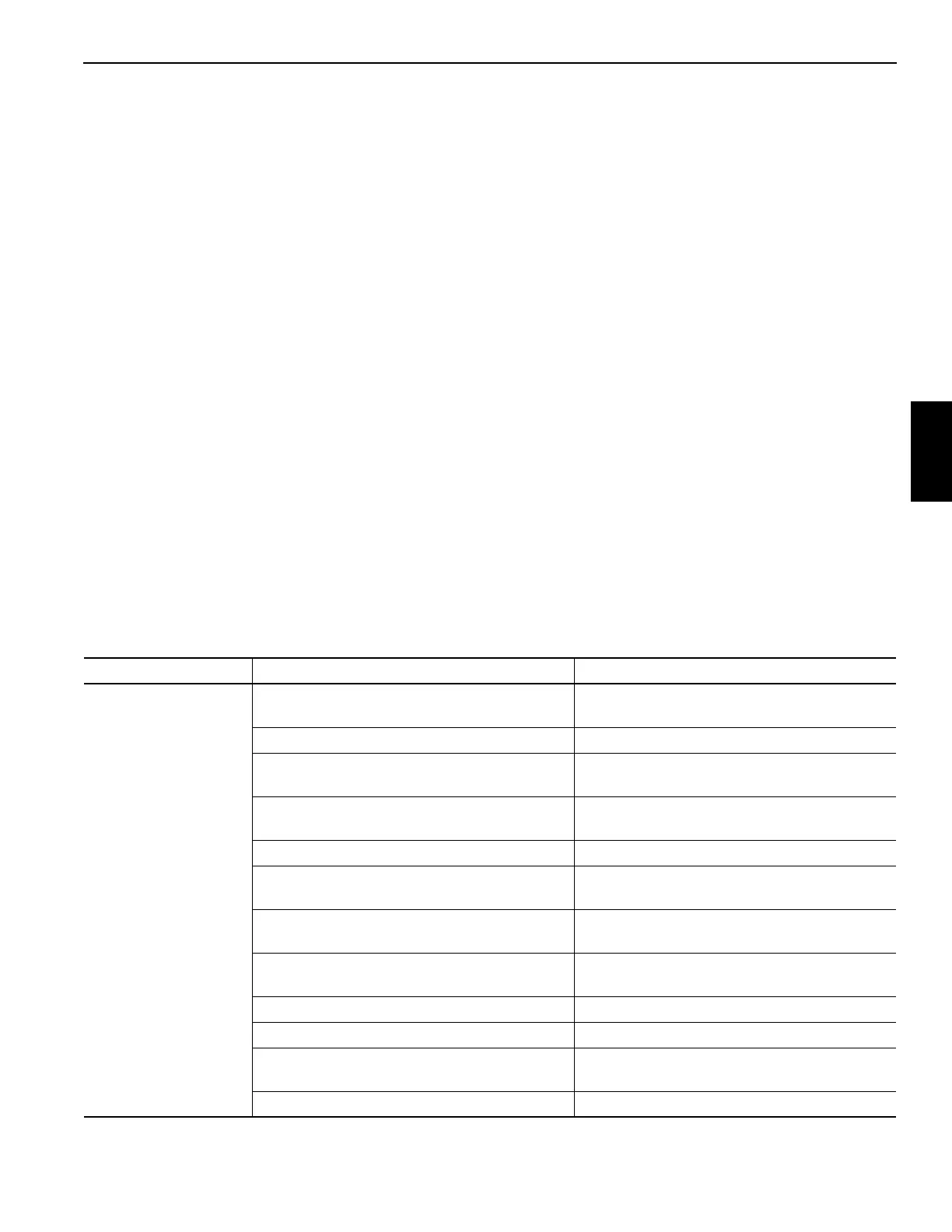

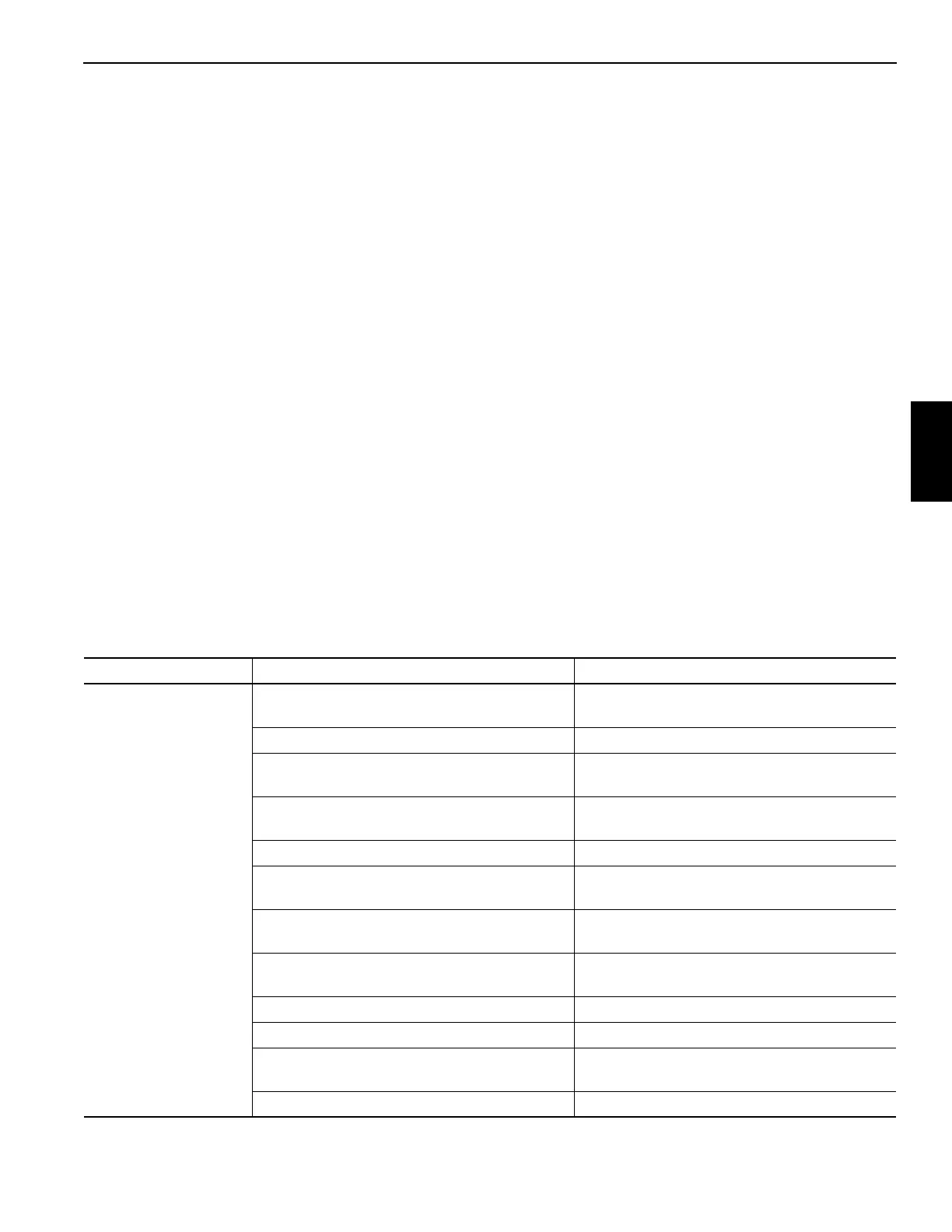

Table 4-2

Troubleshooting

SYMPTOM PROBABLE CAUSE SOLUTION

1. Erratic operation of

extending

telescoping

cylinder.

a. Low hydraulic oil level. a. Check system for leaks. Make repairs

as needed. Fill reservoir.

b. Damaged relief valves. b. Repair or replace relief valves.

c. Air in telescope cylinder. c. Bleed by lowering telescope cylinder

below horizontal.

d. Low engine rpm. d. Increase engine rpm to recommended

setting.

e. Lack of lubrication on boom sections. e. Properly lubricate all boom sections.

f. Extremely tight boom extension

sheaves.

f. Inspect and properly lubricate boom

extension sheaves.

g. Improper boom alignment caused from

side loading.

g. Reduce and properly hoist load.

h. Worn boom wear pads. h. Replace wear pads and properly

lubricate.

i. Distorted boom section. i. Replace distorted section.

j. Damaged telescope cylinder. j. Repair or replace cylinder.

k. Clogged, broken, or loose hydraulic

lines or fittings.

k. Clean, tighten, or replace lines or

fittings.

l. Damaged control valve. l. Repair or replace control valve.

Loading...

Loading...