Published 08-25-09, Control # 077-04 1-17

RT9130E SERVICE MANUAL INTRODUCTION

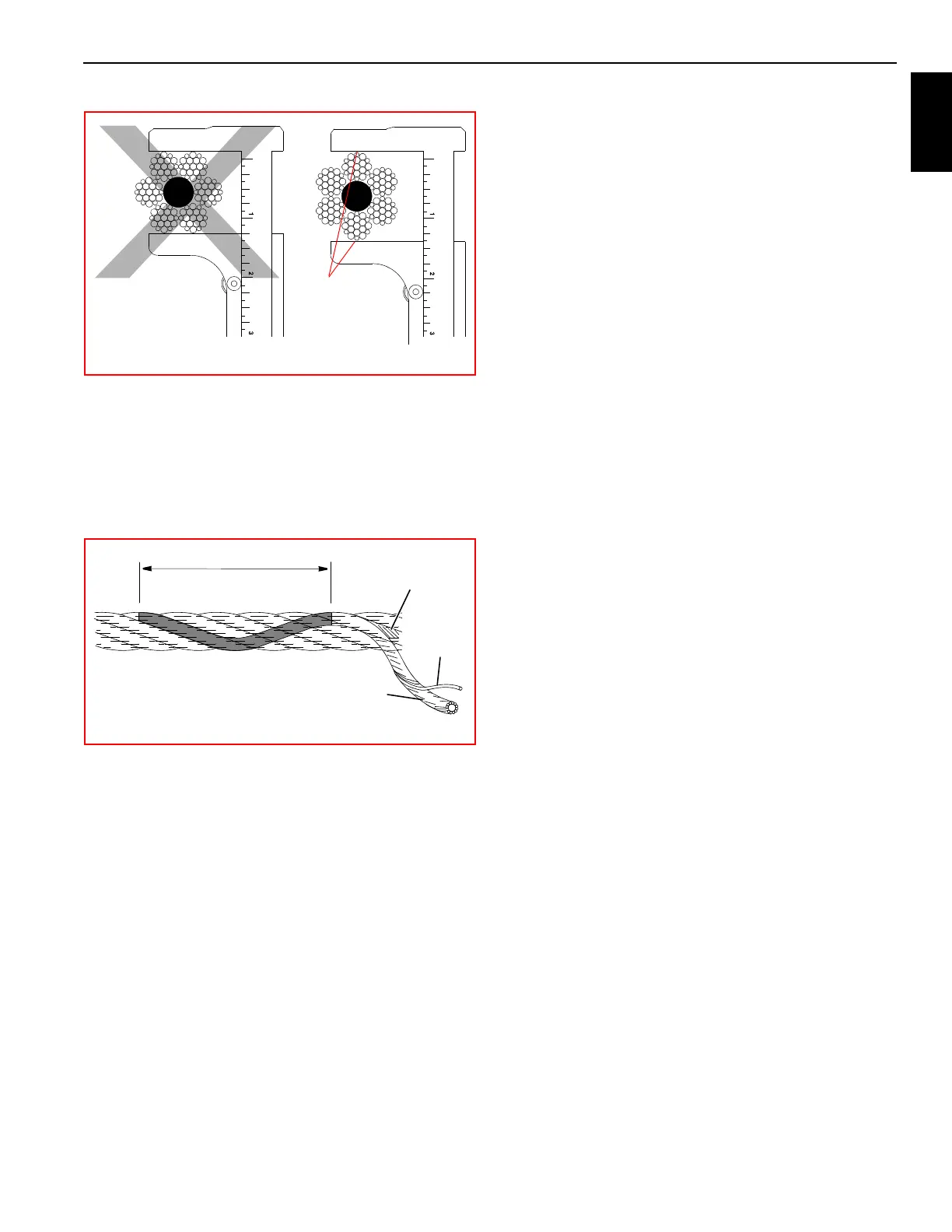

13. When checking for broken wires (5) ((Figure 1-7)) relax

the rope, move it off “pick-up points”, and flex it as much

as possible. Use a sharp awl to pick and probe between

wires and strands, lifting any wire which appears loose

or moves excessively. Defect in the rope is spoke of in

relations to “Lay Length” (2) which is the d

istance

measured along rope in which one strand (3) makes one

complete revolution around core (4).

Wire Rope Inspection (Running Ropes and

Pendant Cables)

Wire rope should be inspected frequently/daily and

periodically/yearly in accordance with the following

information excerpted from a National Consensus Standard

as referenced by Federal Government Agencies.

Recommended inspection intervals may vary from machine

to machine and may vary based on environmental

conditions, frequency of lifts, and exposure to shock loads.

The inspection time intervals may also be predetermined by

state and local regulatory agencies.

NOTE: Wire rope may be purchased through Manitowoc

CraneCARE.

Any deterioration observed in the wire rope should be noted

in the equipment inspection log and an assessment

concerning wire rope replacement should be made by a

qualified person.

Keeping Records

A signed and dated report of the wire rope’s condition at

each periodic inspection must be kept on file at all times. The

report must cover all inspection points listed in this section.

The information in the records can then be used to establish

data which can be used to determine when a wire rope

should be replaced.

It is recommended that the wire rope inspection program

include reports on the examination of wire rope removed

from service. This information can be used to establish a

relationship between visual inspection and the rope’s actual

internal condition at the time of removal from serivce.

Frequent Inspection

A frequent daily visual inspection is recommended for all

running ropes in service. This inspection should be made on

all wire rope which can be expected to be in use during the

day’s operation. This inspection should be used to monitor

progressive degradation and to discover severe damages

necessitating wire rope replacement such as:

1. Distortion, Kinking, Crushing, Un-stranding, Bird caging,

Reduction of diameter, etc.

2. General corrosion.

3. Broken or cut strands.

4. Number, distribution and type of broken wires.

5. Evidence of core failure.

6. End fitting wear/abrasion.

Pay particular attention to areas of the rope where wear and

other damage is likely to occur:

7. Pick-up Points: Sections of wire rope that are

repeatedly stressed during each lift, such as those

sections in contact with sheaves.

8. End Attachments: The point where a fitting is

attached to the wire rope or the point where the wire

rope is attached to the drum.

9. Abuse Points: The point where the wire rope is

subjected to abnormal scuffing and scraping.

Periodic Inspection

Wire rope should be inspected periodically/annually or at a

shorter time interval if necessitated by environmental or

other adverse conditions, and shall cover the entire length of

the wire rope. Only the outer surface of the wire rope need

be inspected, and no attempt should be made to open the

rope. Periodic inspection should include all items listed

under frequent inspection plus the following:

Loading...

Loading...