3-6 Published 08-25-09, Control # 077-04

ELECTRICAL SYSTEM RT9130E SERVICE MANUAL

continuity through its coil, replace the relay. Make circuit

repairs to accessory control circuit as needed.

4. If the problem remains, check the accessory relay K1 or

K2 contacts and the accessory power circuit. Replace

relay if its contacts stay open when the coil is energized.

Make circuit repairs as needed.

Troubleshooting Swivel-Caused Electrical

Problems

Many crane component electrical troubles can be traced to

the electrical swivel. Troubles common to the swivel are

improper mounting, foreign material between the brushes

and slip rings, incorrect wiring from the swivel to the

components, incorrect wire size, worn brushes, improper

spring tension on the brush assembly, and loose setscrews

on the slip ring assembly. Refer to the electrical schematic

and wiring diagram for slip ring connections and amperages.

Connector Troubleshooting

The cause of an electrical problem may be a loose or

corroded connection in the pin or socket connectors. Check

the connectors to ensure that the pins and sockets are

properly seated and engaged. If the pins and sockets show

any signs of corrosion, use a good quality electrical contact

cleaner or fine sandpaper to clean them. When the pins or

sockets show signs of arcing or burning, it will probably be

necessary to replace them.

After cutting the pin or socket off, the wire will most likely be

too short. Using a wire that is too short will allow pressure to

be applied to the pin or socket and wire where they are

crimped when the pin or socket is inserted in the plug or

receptacle. Add a short length of the same size wire to the

short wire by crimp splice or solder. Use heat shrinkable

tubing or other suitable material to insulate the splice.

Table 3-2

Deutsch Extraction Tool Table

Table 3-3

Deutsch Crimping Tool Table

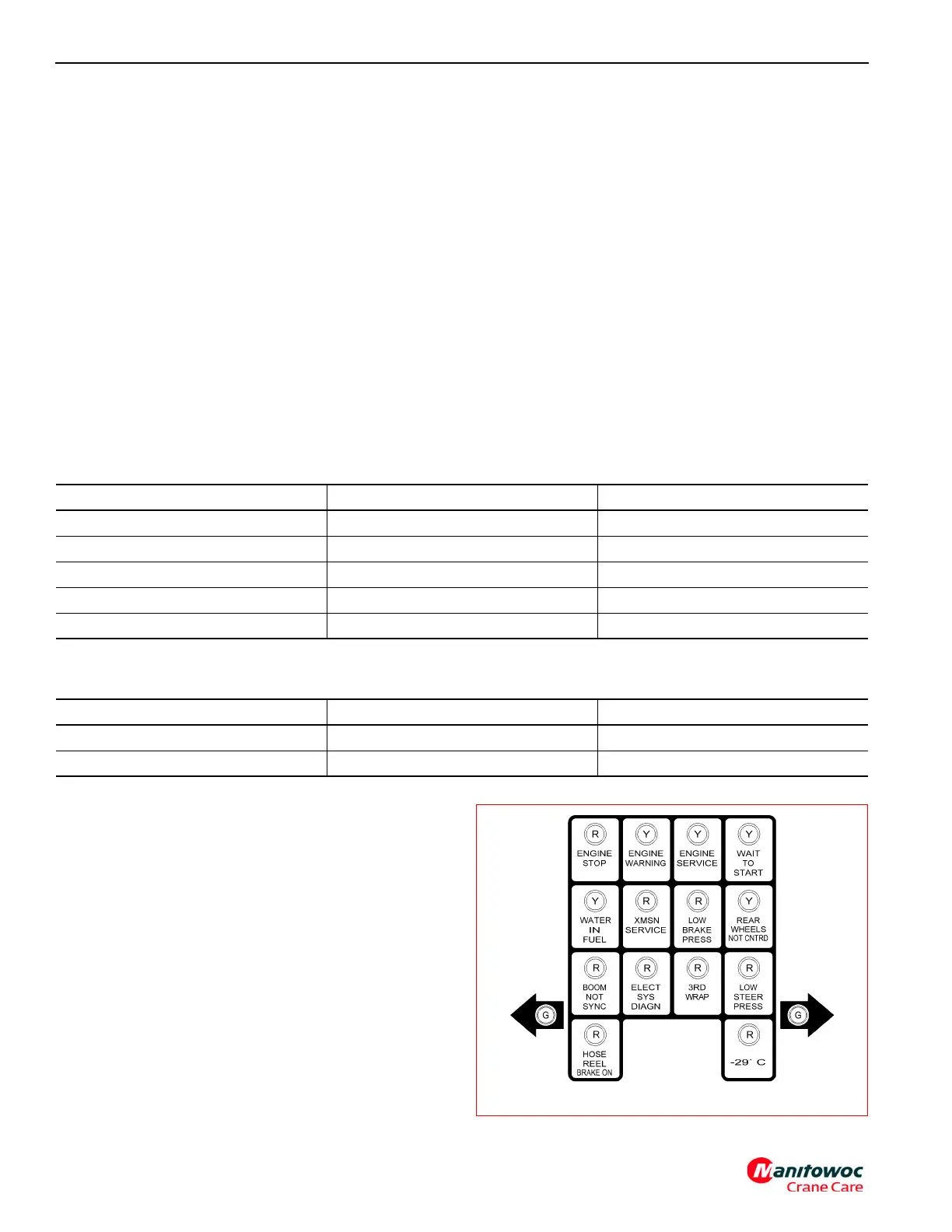

Indicator Lights and Diagnostic Light

The front console indicator lights (Figure 3-8) are located in

the cab on the center of the front console. The lights are

linked to various parts of the crane by the control module and

notify the operator when a certain condition occurs during

the operation of the crane. When the ignition key is turned to

the ACC or RUN position the indicator lights go through all

operations check to see if the lights are working. This

operation check takes about two seconds in which all of the

lights except for the Hoist Third Wrap and Low Steer

Pressure (as applicable) lights turn on and off allowing the

operator to know that the lights are working. For more

description on the front console indicator lights, refer to

Section 3 in the Operator’s Manual

Description Deutsch Part Number Grove Part Number

12 gauge wire 114010 9-999-100194

16 gauge wire 0411-204-1605 9-999-100195

8-10 gauge wire 114008 7-902-000012

4-6 gauge wire 114009 7-902-000009

20-24 gauge wire 0411-240-2005 9-999-102084

Description Deutsch Part Number Grove Part Number

12, 14, 16, 18, 20, 22, 24 gauge wire HDT-48-00 9-999-100808

4, 6, 8, 10 gauge wire HDT04-08 9-999-100842

Loading...

Loading...