Published 08-25-09, Control # 077-04 5-15

RT9130E SERVICE MANUAL HOIST AND COUNTERWEIGHT

HOIST DRUM ROTATION INDICATOR

SYSTEM

Description

The hoist drum rotation indicator system is an electrically

operated system that provides the operator with a touch

indication of drum rotation so he will know if and at what

speed the hoist drum is rotating, even under the most

distracting conditions.

The rotation indicator system consists of three separate

electrical components; the rotation indicator sensor, drum

rotation indicator control module (CPU), and thumb thumper

solenoid. The rotation sensor and control module (CPU) are

located on the hoist. The pulsing thumb thumper solenoid is

located in the applicable hoist control lever handle.

Maintenance

General

Proper circuit operation can be checked for each individual

electrical component. If a malfunction occurs within the

system, repairs should be limited to finding and replacing the

faulty component(s). To determine which component is at

fault, use the self diagnostic LEDs on the CPU. If difficulty

persists, contact your local dealer for additional

troubleshooting aid.

Rotation Sensor

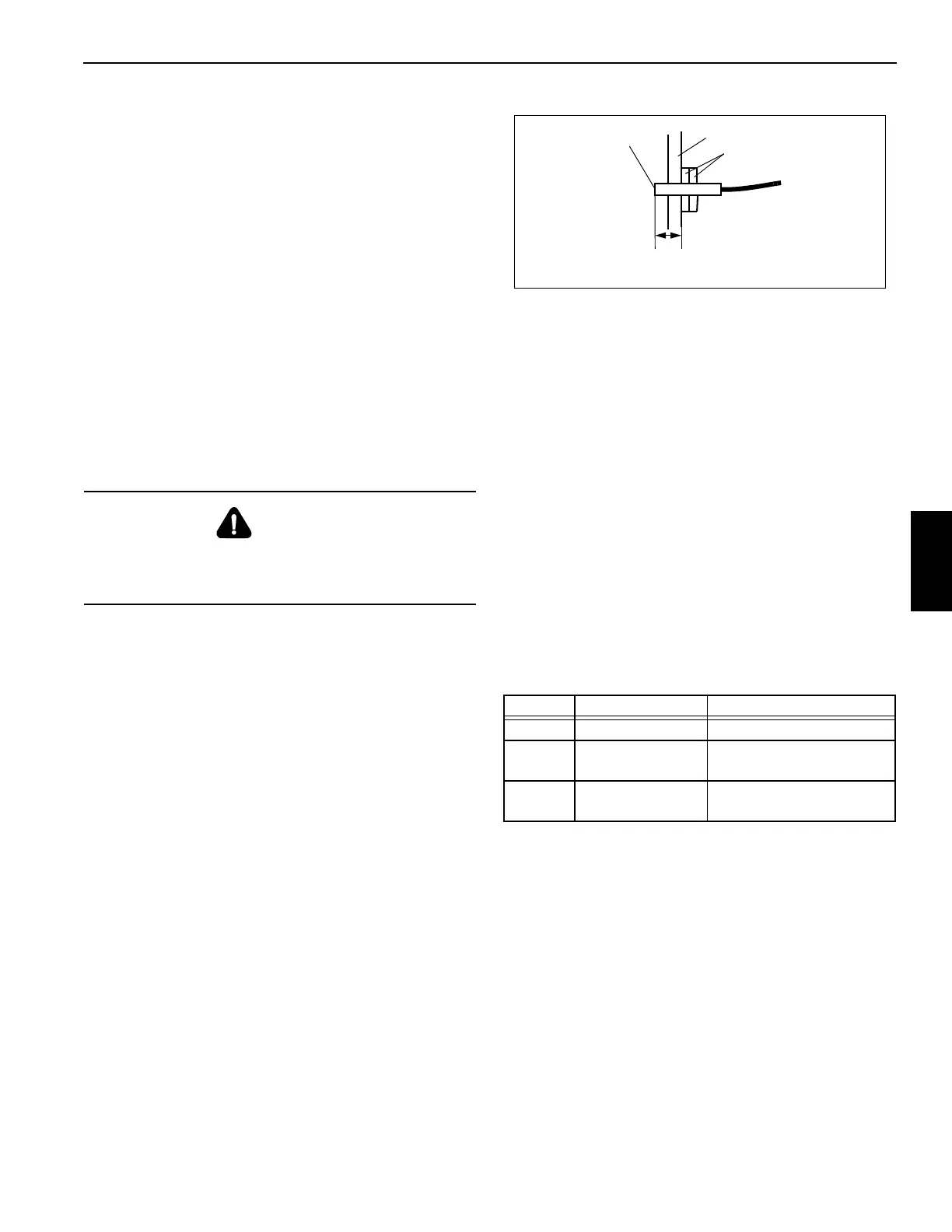

The rotation sensor is screwed into the hoist support end

bracket that holds the hydraulic motor (Figure 5-5). It senses

the rotation of the drum. When installing the sensor, ensure

its sensing end is 1.21 inch (31 mm) from the first lock nut.

(This is the length of the sensor from its sensing end through

to the outside surface of the hoist support end bracket.) If

sensor will not work properly, loosen both lock nuts and turn

the sensor counterclockwise up to one turn, then retighten

lock nuts to hold sensor position. If sensor will still not work

properly, ensure its sensing end is 1.21 inch (31 mm) from

the first lock nut, then turn the sensor clockwise up to one

turn, then retighten lock nuts to hold sensor position.

Drum Rotation Indicator Control Module

(CPU)

The control module (CPU) is bracket mounted to the upper

hoist motor attaching bolt. It provides LEDs for checking

proper circuit operation, as well as providing power to the

rotation sensor. It also sends a signal to the thumper

solenoid proportional to the sensor.

Thumb Thumper Solenoid

The thumb thumper solenoid provides feedback proportional

to the hoist line speed by pulsing the rubber button on top of

the hoist control lever.

Troubleshooting

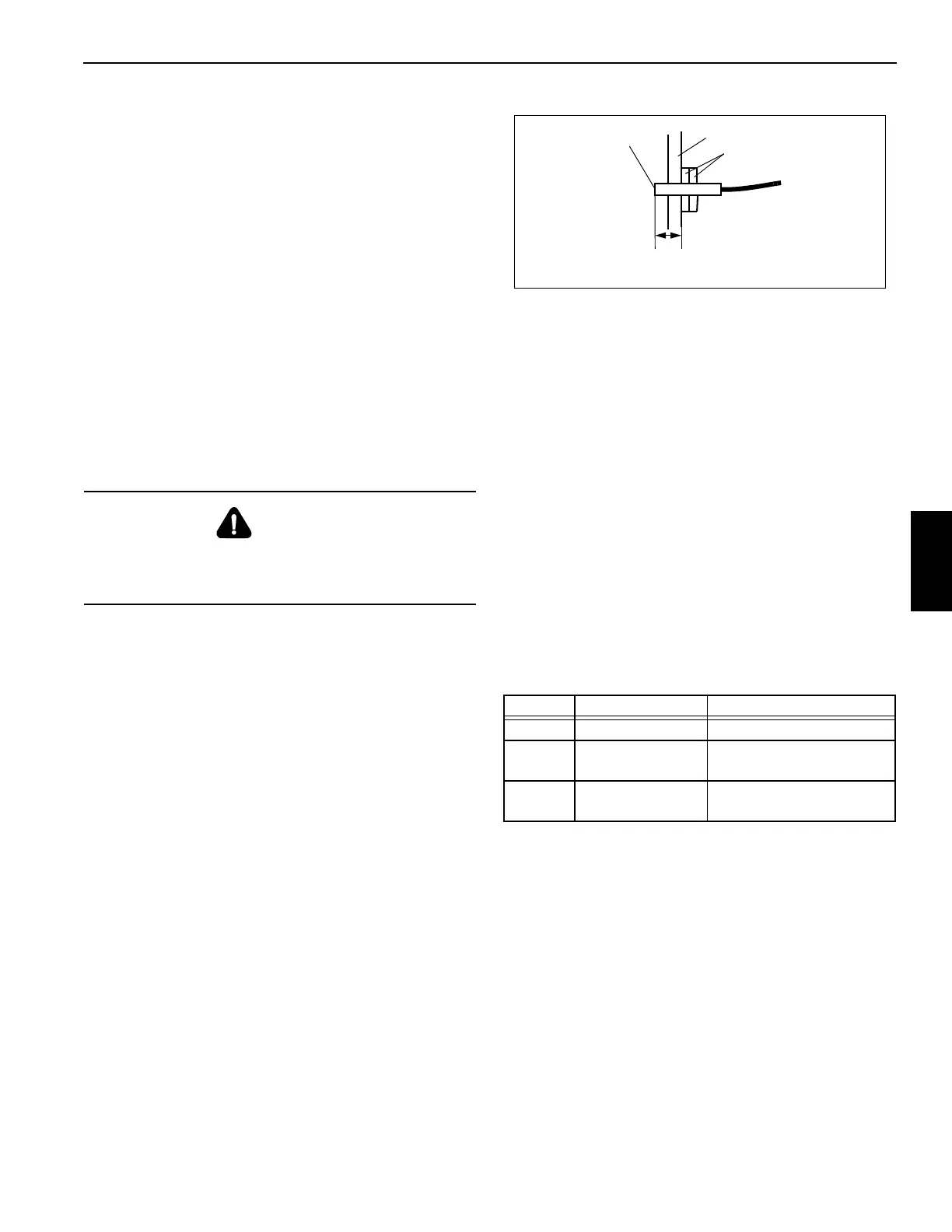

To troubleshoot the system, use the three diagnostic LEDs

located on the control module (CPU). Under normal

operating conditions (hoist drum rotating) the diagnostic

LED’s function as shown in the following table.

Table 5-2

NOTE: The following paragraphs troubleshoot the system

using the diagnostic LEDs. The hoist drum must be

rotating during all troubleshooting.

Green LED

Turn the ignition switch on. Verify that the green LED is on.

The LED should stay on as long as accessory power is on. If

the green LED is not on, either the voltage did not arrive at

the CPU, or the CPU is defective and needs to be replaced.

If the green LED repeatedly flashes once with the red and

yellow LEDs off, the solenoid circuit is shorted. If the green

LED repeatedly flashes two times with the red and yellow

LEDs off, the CPU is defective. If the green LED repeatedly

flashes three times with the red and yellow LEDs off, the

DANGER

Disconnect the batteries before performing any

maintenance on this system. Serious burns may result

from accidental shorting or grounding of live circuits.

LED OPERATION DEFINITION

Green On continuously Current applied to sensor

Red

Pulses on, varies

with speed

Sensor signal received

Yellow

Pulses on, varies

with speed

Solenoid pulse working

Support End Bracket

1.21 in. (31 mm)

Lock Nuts

Sensing End

FIGURE 5-5

7068

Loading...

Loading...