Published 08-25-09, Control # 077-04 7-15

RT9130E SERVICE MANUAL POWER TRAIN

Air Cleaner Body

Before installing the filter element, remove foreign material

(leaves, lint or other foreign matter) that may have collected

inside the air cleaner body. Inspect the inside of the body for

dents or other damage that would interfere with air flow or

with the fins on the element or inside the body. Repair any

body dents, being careful not to damage the sealing

surfaces. Be sure to clean the sealing surface of the outlet

tube and the inside of the outlet tube, taking care not to

damage the sealing area on the tube.

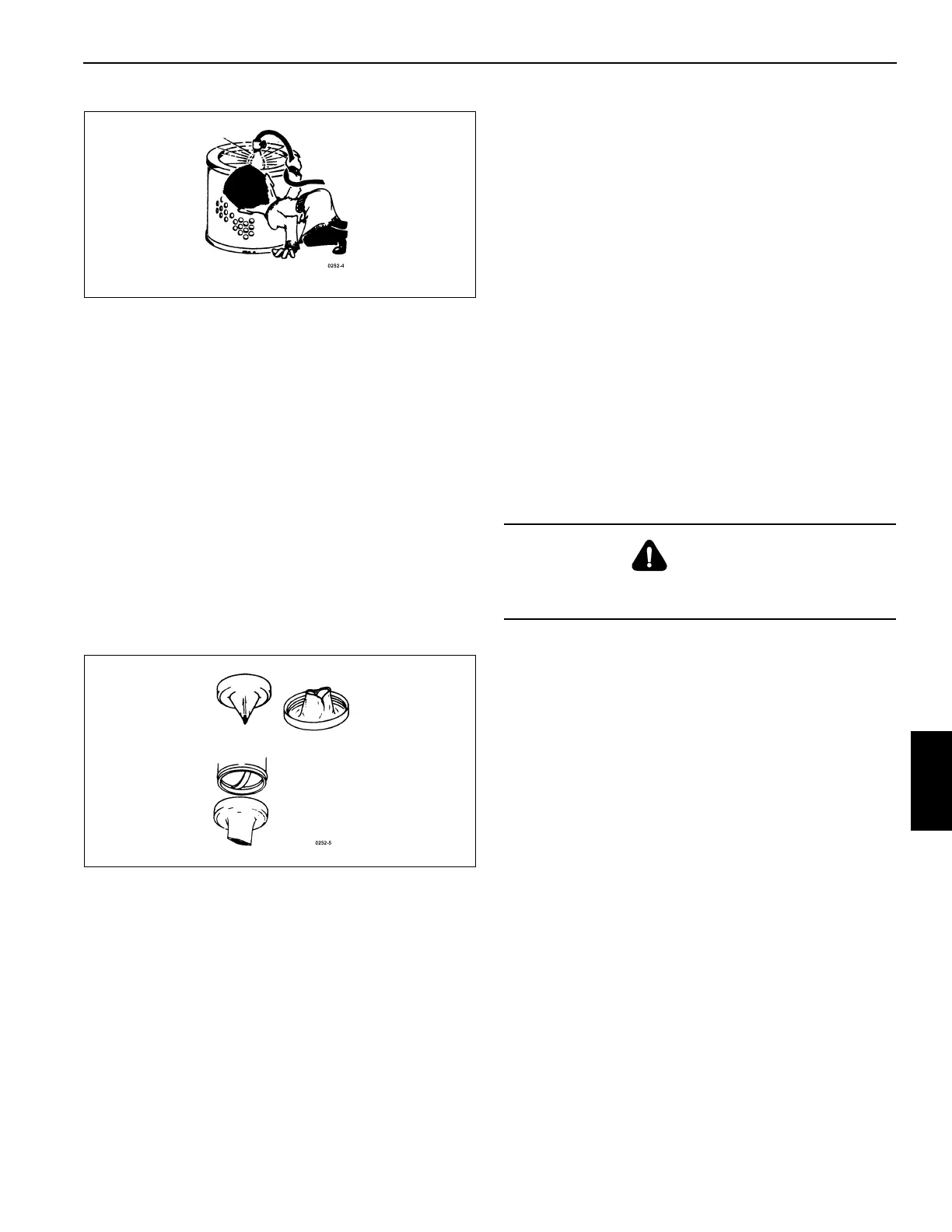

Vacuator Valve

Vacuator valves are designed to expel loose dust and dirt

from the air cleaner body automatically, thus lengthening the

element service life. The valve lips must point straight down

and be kept free from debris to operate effectively. Mud and

chaff can lodge in these lips periodically and hold them open

during engine operation (Figure 7-12).

Check the condition of the valve and lips frequently and keep

them clean. The valve lips should be open only when the

engine is shut down, or running at low idle speed. If the valve

is turned inside out, check for a clogged air cleaner inlet.

Malfunction of this valve does not reduce the air cleaner

effectiveness, but does allow the element to get dirty faster

and reduces serviceable life. If a valve is lost or damaged,

replace it with a new valve of the same part number.

Duct Work

1. Check the intake pipe cap and screen for accumulation

of leaves, trash, and other debris that could restrict air

flow. Repair the screen or replace the cap if any large

holes are found in the screen.

2. Check all mounting hardware for security to eliminate

possible vibration of intake piping. Such vibration leads

to early failure of hoses, clamps, and mounting parts,

and can cause hoses to slip off the connecting pipes,

allowing un-filtered air into the engine air intake.

3. Check hoses for cracks, chafing, or deterioration, and

replace at the first sign of probable failure.

MUFFLER

NOTE: Standard muffler and CE muffler are similar in

removal and installation (Figure 7-13) despite the

differences in the two mufflers, the exhaust

tailpipes, and the mounting bracket weldments.

Removal

1. Remove muffler clamps to free exhaust tailpipe from

muffler and muffler mounting bracket.

2. Remove seal clamp to free muffler from exhaust tube.

3. Remove mounting bands to free muffler from muffler

mounting bracket. As needed, remove capscrews and

nuts to free muffler mounting bracket from its mountings.

4. Inspect muffler, exhaust tailpipe, exhaust tubes, bracket,

and attaching hardware. Repair or replace any of these

parts if damaged or missing.

Installation

1. Secure the muffler to the exhaust tube with a seal clamp.

2. Install the exhaust tailpipe on the muffler. Secure the

exhaust tailpipe to the muffler and muffler mounting

bracket with muffler clamps. Adjust the seal clamp as

needed.

3. Secure the muffler mounting bracket to its mountings

with capscrews and nuts as needed. Secure the muffler

to the muffler mounting bracket with mounting bands.

DANGER

Do not touch muffler or exhaust parts until they are at

ambient temperature. Severe burning may result.

Loading...

Loading...