2-26 Published 08-25-09, Control # 077-04

HYDRAULIC SYSTEM RT9130E SERVICE MANUAL

Procedure I - For Checking Swing Valve

Work Port Relief Pressure

1. Remove cap and install pressure gauge on swing valve

inlet test port (Figure 2-13).

2. With the swing lock Engaged and the engine running at

FULL RPM, swing LEFT and adjust “A” port swing relief

to 17.2

± 0.4 MPa (2500 ± 50 PSI).

3. With the swing lock Engaged and the engine running @

FULL RPM, swing RIGHT and adjust “B” port swing

relief to 17.2

± 0.4 MPa (2500 ± 50 PSI).

4. Remove pressure gauge from the swing inlet test port

and reinstall cap.

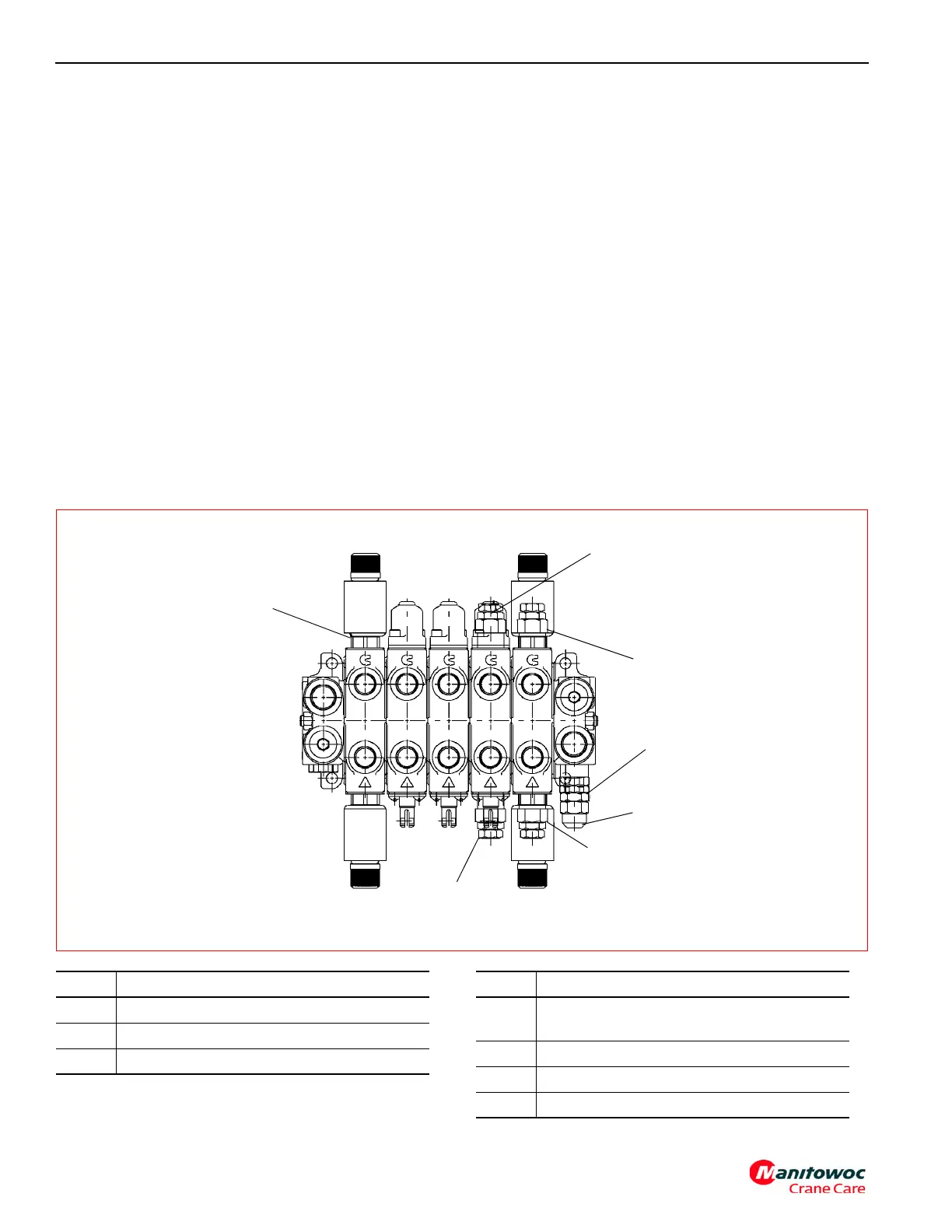

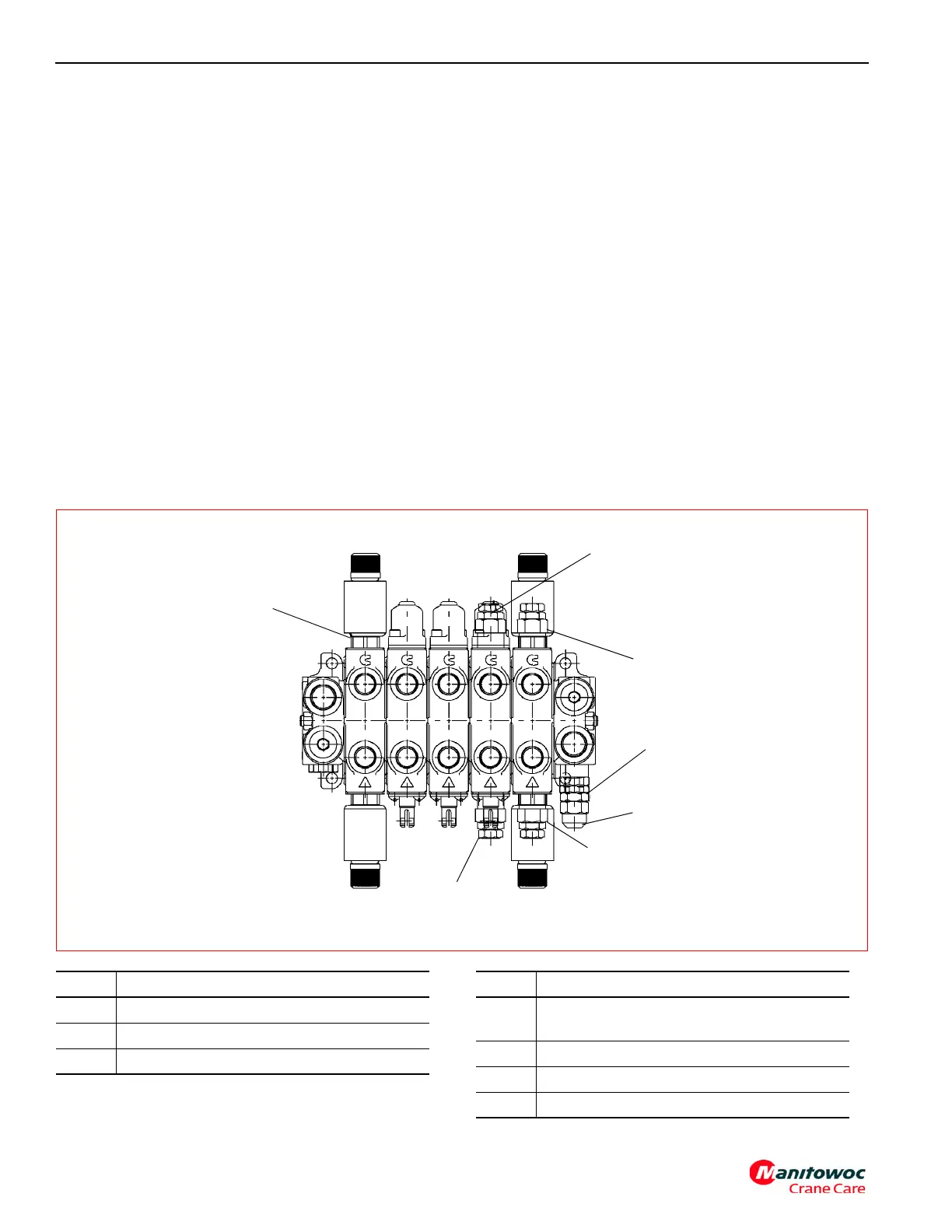

Procedure J - For Checking Relief Setting

for Counterweight Supply Control Valve

1. Remove cap and install gauge on load sense relief test

port on main directional control valve (Figure 2-14).

2. Operate the counterweight directional control valve by

fully raising or lowering the counterweight cylinders.

Adjust the counterweight removal directional control

valve load sense relief valve to 26.2

± 0.4 MPa (3800 ±

50 PSI).

3. In the cab, press the luffing extension switch to ON and

the luffing raise/lower switch to LOWER in the LH

armrest. Adjust the luffing extension “B” port relief valve

to 10.0

± 0.4 MPa (1450 ± 50 PSI).

4. In the cab, press the cab tilt switch to the RAISE position

and adjust the cab tilt “A” port relief valve to 17.2

± 0.4

MPa (2500

± 50 PSI).

5. In the cab, press the cab tilt switch to the LOWER

position and adjust the cab tilt “B” port relief valve to 17.2

± 0.4 MPa (2500 ± 50 PSI).

FIGURE 2-14

Counterweight Removal Directional Control Valve

1

2

3

4

5

6

7

Item Description

1 Luffing Extension Relief “B” Port

2 Counterweight Pin Relief ‘B” Port

3 Cab Tilt Relief “B” Port

Item Description

4

LS Relief Valve Adjustment: Turn Screw

Clockwise to Increase Pressure

5 Remove Cap

6 Cab Tilt Relief “A” Port

7 Counterweight Pin Relief “A” Port

Loading...

Loading...