© Guldmann GB-1394/11/08

70

4. electrIcal connectIon

Installation of Double Combi-lock

Motor unit is installed as described on page 65.

Installing the safety locks on fixed rail

• The motor unit with tongues and safety locks for the

fixed rails are pushed together into the T track in the

Mini rail.

• The safety locks should be installed so that their edges

are flush with the front edge of the rail.

• Fasten the safety locks with two M4 x 10 mm locking

screws.

• Use the safety lock as a drill gauge and hold it precisely

in position while drilling. A screw clamp can also be

used to keep the safety lock in position while drilling.

Bottom of safety lock

must fit tightly against bottom of

rails.

• Drill the holes and make the M4 threads. Clean up

components and mount the screws.

• Fasten the motor unit. Check that the tongues are flush

with the front edge of the rails when they have been

drawn back mechanically to their rearmost position.

Install brackets for Double Combi-lock. Before finally

fastening the brackets, check that the rails are level,

both horizontally and vertically. If necessary adjust the

brackets.

Installing the safety locks on traverse rails

• Loosen the two M8 nuts in the T track plate so that the

safety locks can be pushed into the T track of the rail.

• The safety locks should be installed so that their edges

are flush with the front edge of the rails.

• When the safety locks have been correctly installed, the

two M8 nuts can be tightened.

• Check that there is a space of minimum 1 mm

(1/15”)from the activation pin in the T track to the bottom

of the T track.

• Fasten the safety locks with M4 x 10 mm locking

screws.

• Use the safety lock as a drill gauge.

• Drill the holes and make the M4 threads. Clean up

components and mount the screws.

Important

After installation has been completed, check that the locks

work in combination, i.e. that they open and close correctly

individually.

All parts have been lubricated from the factory. Do not

lubricate or grease any components or rails

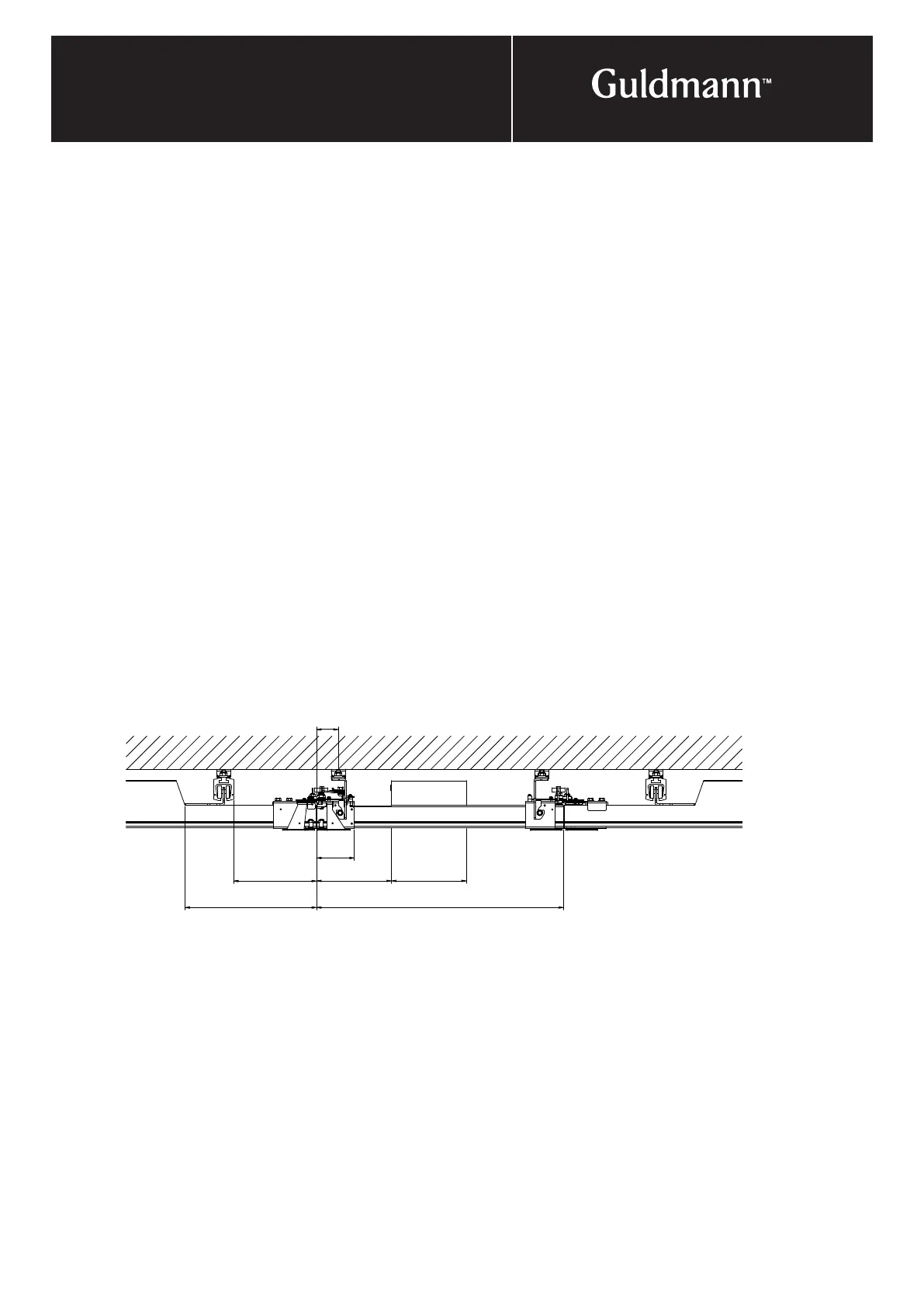

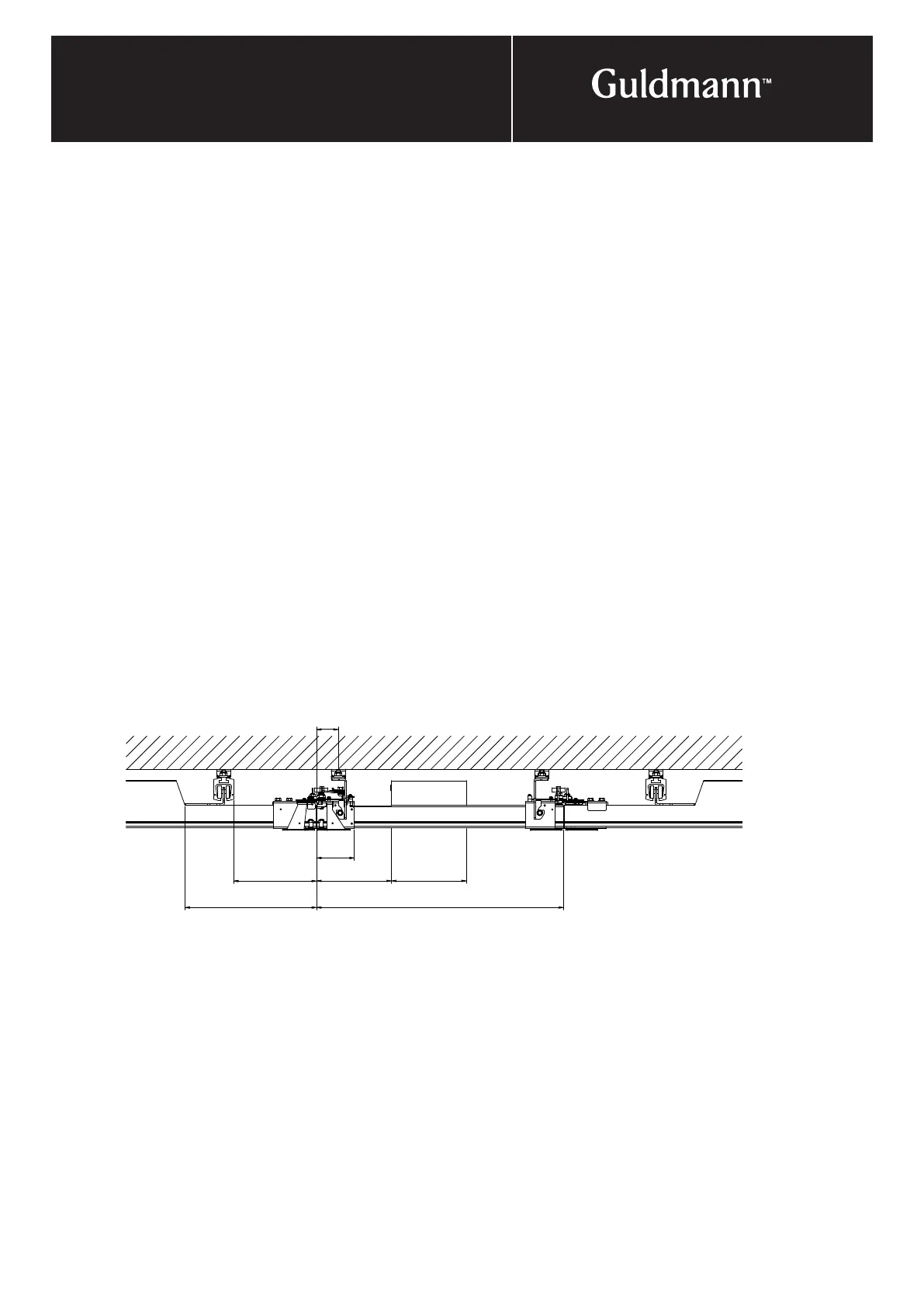

Combi-lock

CL3 double electrical

A. 100 mm (4")

B. min 150 mm (6")

C. 260 mm (10

3

/

8

" )

D. std. 530-930 mm (21

3

/

16

" - 37

3

/

16

")

D. max 2440 mm (97

9

/

16

")

E. 58 mm (2

5

/

16

")

F. min 115 mm (4

9

/

16

")

G. min 255 mm (10

5

/

16

")

Loading...

Loading...