Advanced Information

Theory of Operation

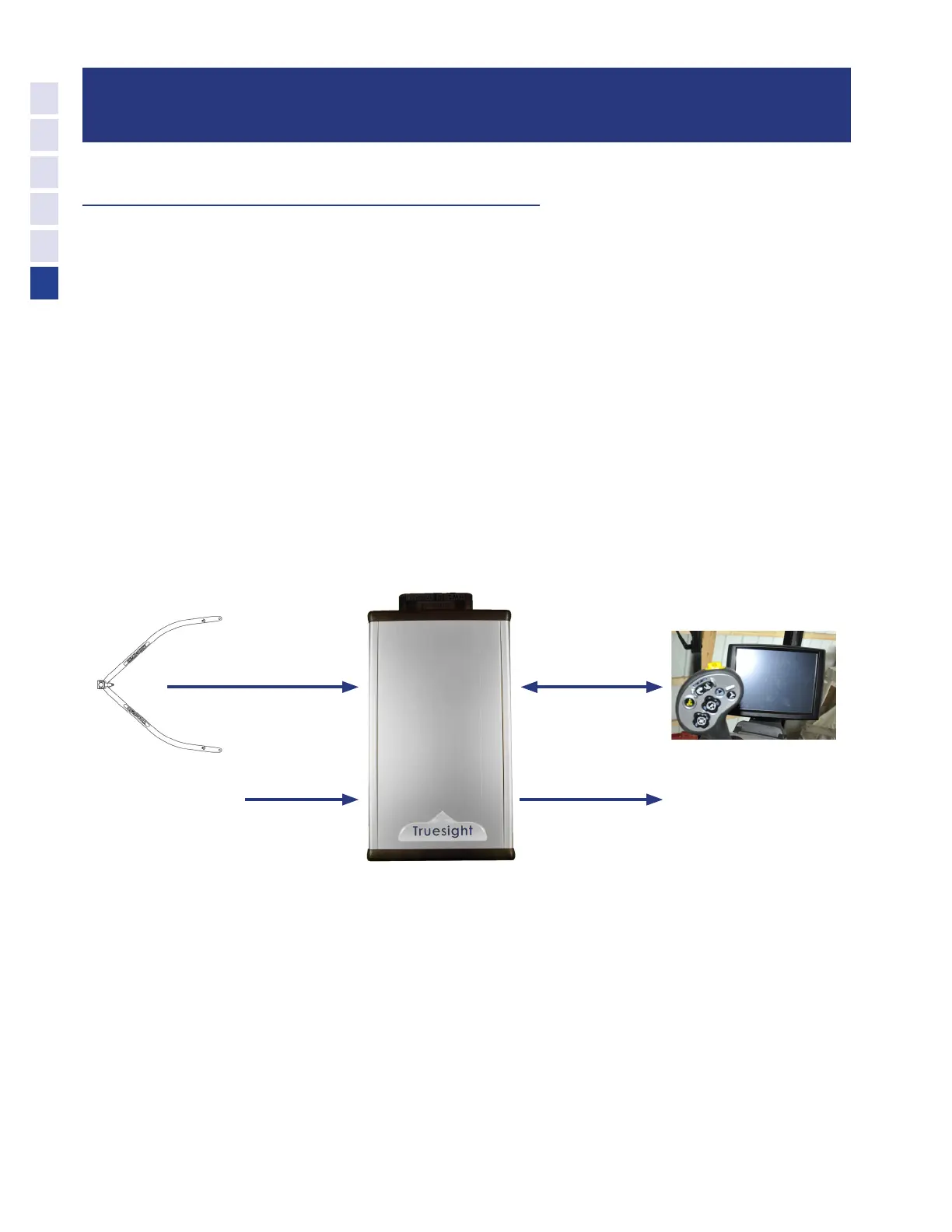

Truesight 2 systems use a single Hall Effect crop sensor assembly mounted on the head to sense the

corn rows and return a voltage to the combine (1-4 volt output). If centered in the row, the crop sensor

output voltage should be 2.5 volts; when stalks fully push the right side wand, the voltage should raise

to 4 volts; when stalks fully push the left side wand the voltage should drop to 1 volt. The output voltage

form both the crop sensor and the combine wheel angle sensor are used by the Truesight 2 controller

to determine the direction the combine needs to be steered. The controller communicates the steer

command by sending a voltage to the autosteer valves or steering motor on the combine (factory or

aftermarket). The operator’s primary interface with the Truesight 2 system is through a VT display, used

for setup, calibration, adjusting settings and running the system. The Truesight 2 controller also receives

information from the operator through the various safeties and sensors. Truesight’s safeties can include

the seat switch, GPS speed sensor, and steering wheel motion sensor. The system can be disengaged by:

rotating the steering wheel, pressing the steering wheel button on the VT, raising the feederhouse (auto-

engage mode), or pressing the foot switch. The system can be engaged by: pressing the steering engage

button on the VT display, lowering the feederhouse (auto-engage mode), or pressing the foot switch.

Wheel Angle Sensor

Steering Device:

Autotrak, Ag Leader,

Outback, Trimble, etc

38

Advanced Info

Loading...

Loading...