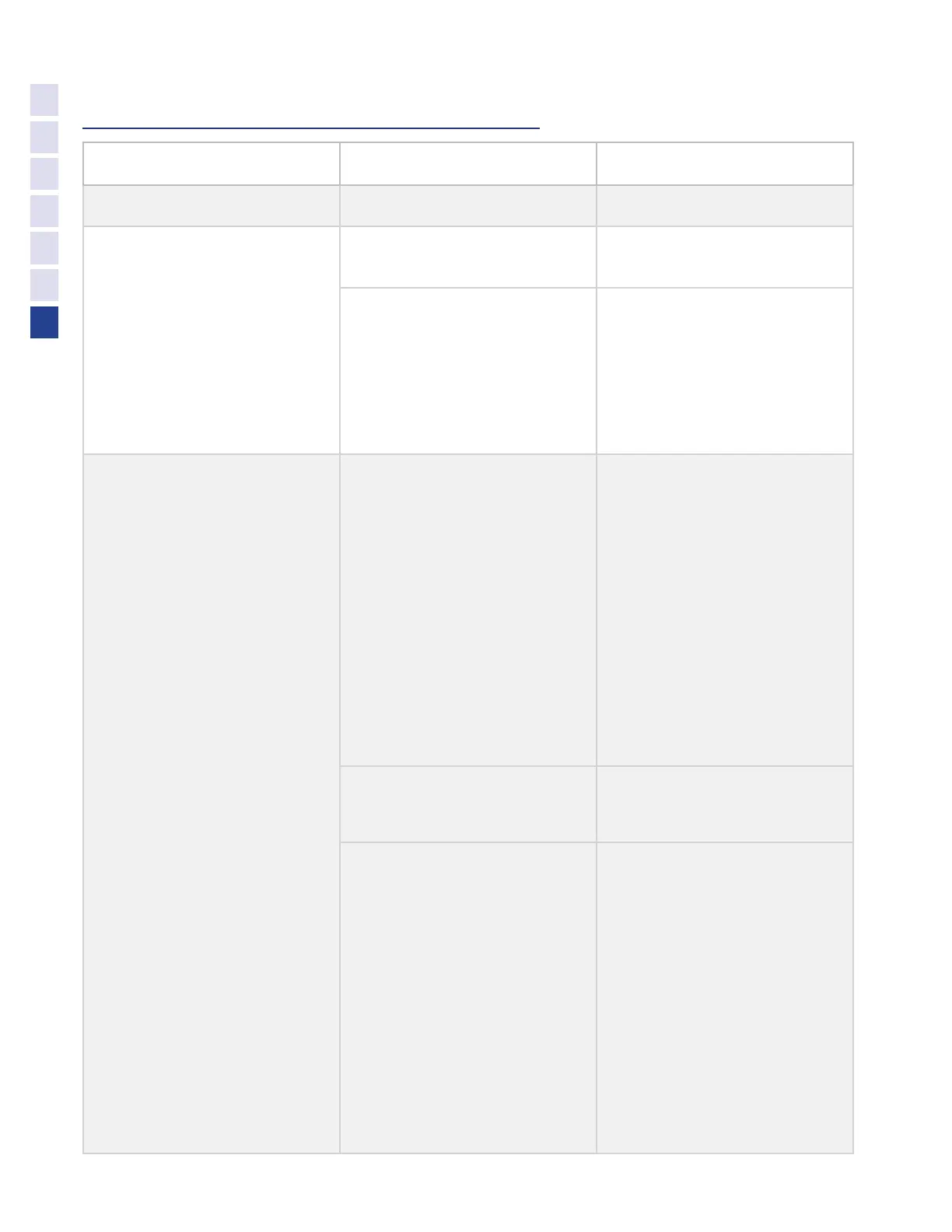

Troubleshooting by Error Codes

Error Code Problem Solution

ER2

Wheel Angle Calibration Incomplete

The Wheel Angle calibration has not

been completed.

Go to >>Cal>>Wheel Angle, and redo

calibration

ER

11

Crop Sensor > 4.7V

Description:

The crop sensor is a 5V hall effect

sensor (works like a potentiometer)

that sends an analog voltage to the

Truesight controller. This error is caused

when the analog voltage coming from

the crop sensor is greater than

4.7V.

To read the current voltage, go to

>>Diag>>Overview

>>Crop Sensor

The crop sensor voltage remains stuck

at

4.78 ±0.05 volts when the crop

sensor is moved.

Switch wires A & C in the harness that

connects to the crop sensor to reverse

polarity.

The crop sensor voltage remains stuck

above 4.9 volts when the crop sensor

is moved.

The signal wire (B) may be shorted

to the power wire (C). Find short and

correct.

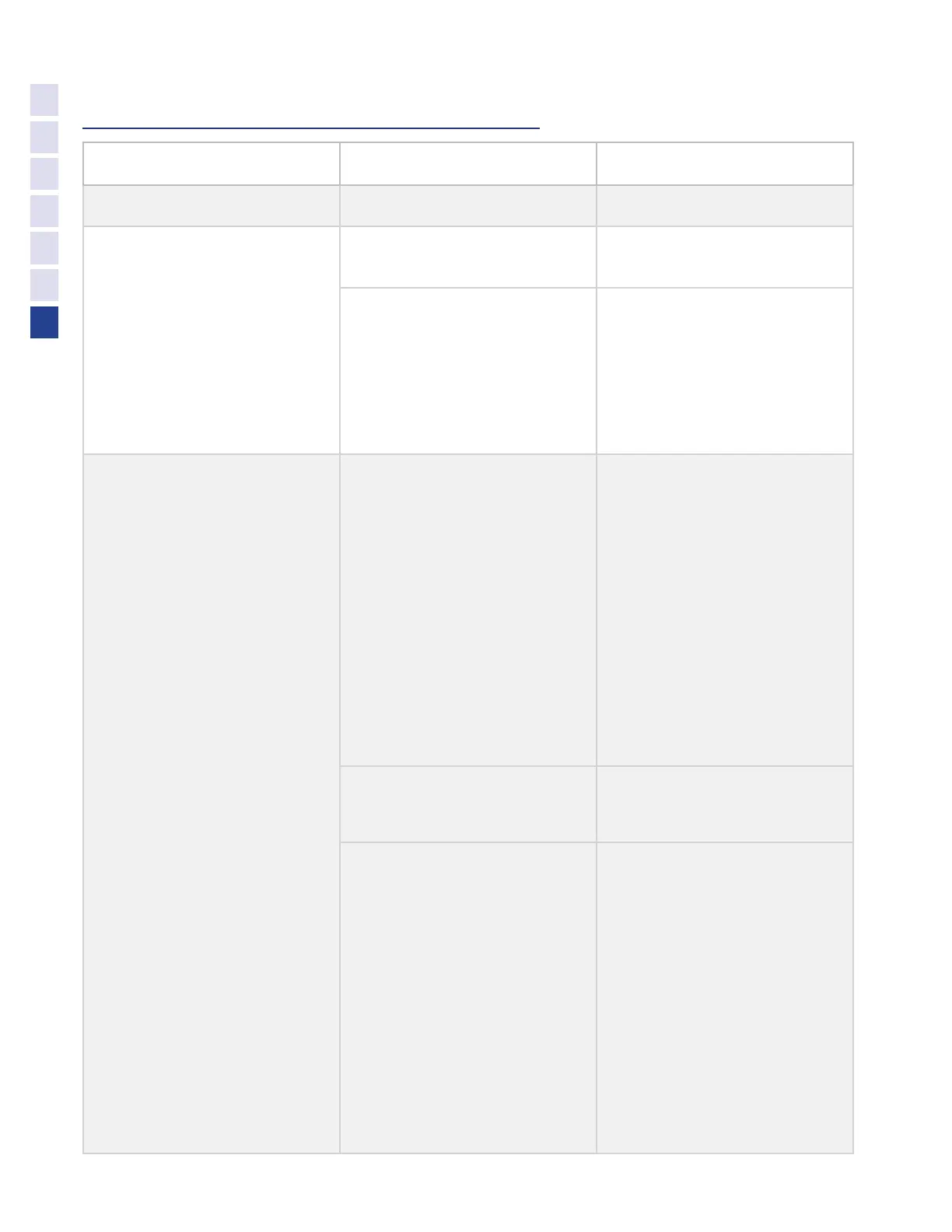

ER

12

Crop Sensor < 0.3V

Description:

The crop sensor is a 5V hall effect

sensor (works like a potentiometer)

that sends an analog voltage to the

Truesight controller. This error is caused

when the analog voltage coming from

the crop sensor is less than

0.3V.

To read the current voltage, go to

>>Diag>>Overview

>>Crop Sensor

There is not

5V between pins A & C

of the sensor harness (Unplug sensor

under snout tip to measure)

Unplug square 4 pin Deutsch connection

at feederhouse (Y

703)and measure

voltage between pins 1 & 3 of wire

coming from combine. If

5V is present,

there is a problem with extension

harness under header. If

5V is not

present, continue to follow the wiring

up toward the cab and unplug square

4

pin Deutsch connection Y

7004/Y7003

and measure voltage of pins

1 & 3 of

connector Y

7003. If 5 volts is present

there is a problem with the extension

harness that runs up the feederhouse,

or in the CIH feeder wiring. If

5V is not

present, there is a problem with main TS

harness. Repair or replace appropriate

harness to supply power to sensor.

Sensor is receiving

5V but there is

not 2.5V±1V between pins A & B of

crop sensor (back probe with sensor

centered and harness connected)

Crop sensor failure, replace sensor

Sensor is receiving 5V but there is

not signal voltage on pin 11 of large

connector on Truesight base in cab

(check with back probes, Reference pin

2 for ground)

With crop sensor centered and harness

connected, back probe

4 pin Deutsch

connection at feederhouse (Y703) and

measure voltage between pins 1 & 2. If

2.5V is not present, there is a problem

with extension harness under header.

If

2.5V is present, continue to follow

the wiring up toward the cab and back

probe pins

1 & 2 of the 4 pin Deutsch

connector Y7003. If 2.5V is not present,

there is a problem with the extension

harness that runs up the feederhouse,

or in the CIH feeder wiring. If

2.5V is

present, there is a problem with main TS

harness. Repair or replace appropriate

harness so signal voltage returns to

Truesight

2.

46

Diagnostics

Loading...

Loading...