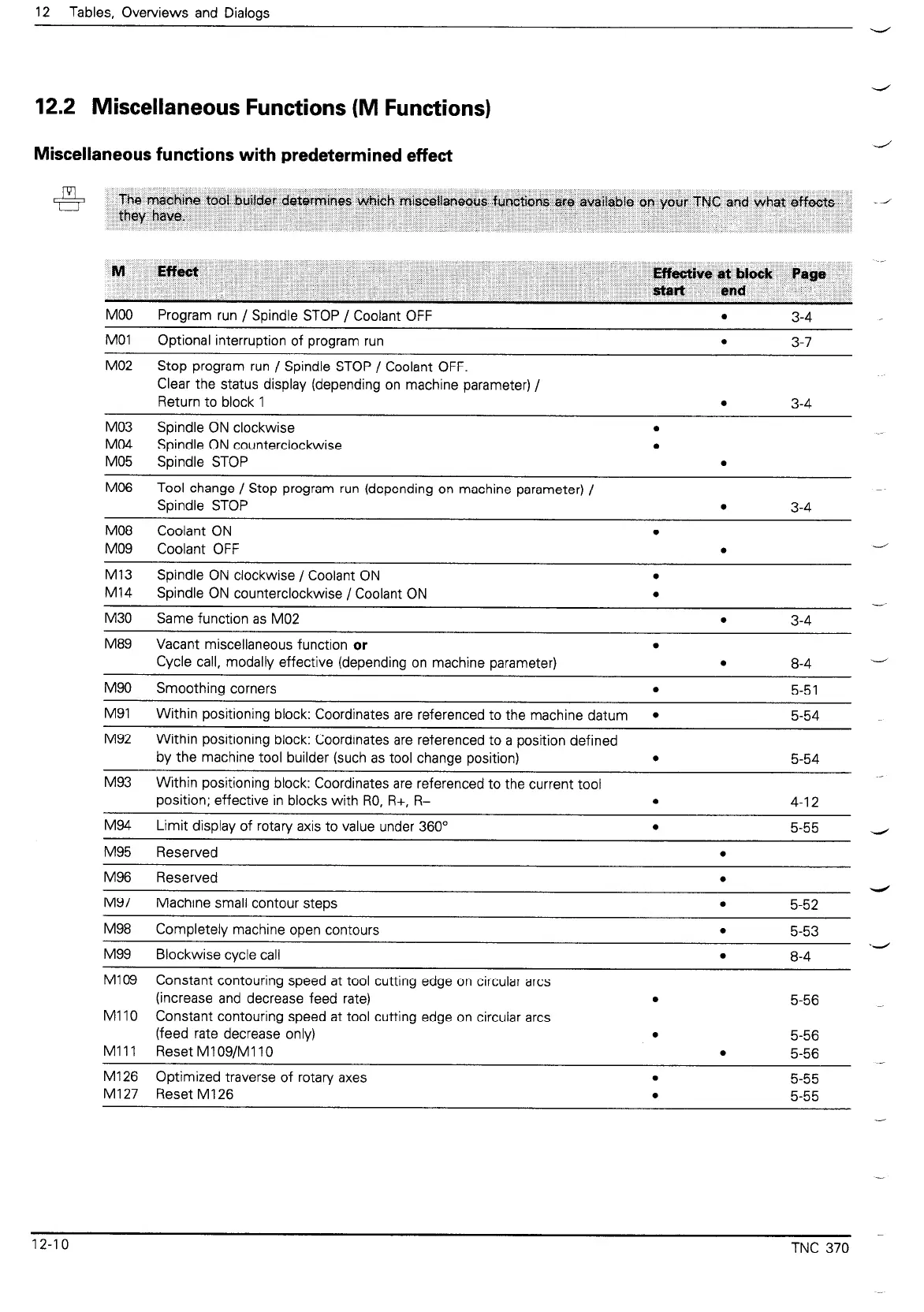

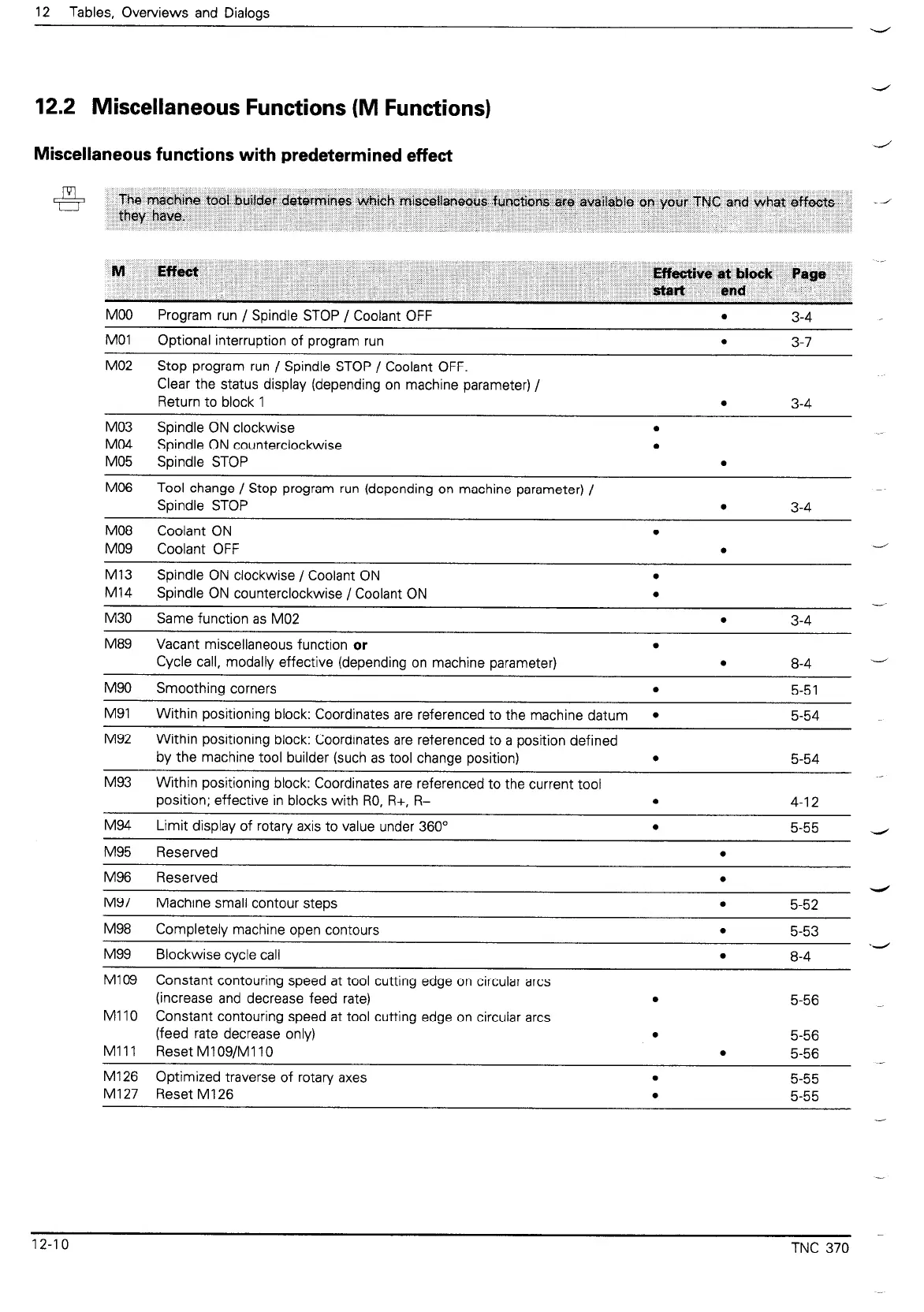

12 Tables, Overviews and Dialogs

12.2 Miscellaneous Functions (M Functions)

Miscellaneous functions with predetermined effect

7%

The machine toat builder dettermines which miscetlaneaus functions are avail&e ctn your TNC and what effects

they have.

MOO Program run / Spindle STOP / Coolant OFF

.

3-4

MO1 Optional interruption of program run

.

3-7

MO2 Stop program run / Spindle STOP / Coolant OFF.

Clear the status display (depending on machine parameter) /

Return to block 1

.

3-4

MO3 Spindle ON clockwise

.

MO4 Spindle ON counterclockwise

.

MO5

Spindle STOP

.

MO6

Tool change / Stop program run (depending on machine parameter) /

Spindle STOP

.

3-4

MO8 Coolant ON

.

MO9 Coolant OFF

.

Ml3

Spindle ON clockwise / Coolant ON

.

Ml4 Spindle ON counterclockwise / Coolant ON

.

M30 Same function as MO2

.

3-4

M89 Vacant miscellaneous function or

.

Cycle call, modally effective (depending on machine parameter)

.

8-4

M90 Smoothing corners

.

5-51

M91 Within positioning block: Coordinates are referenced to the machine datum

l

5-54

M92 Within positioning block: Coordinates are referenced to a position defined

by the machine tool builder (such as tool chancre position)

.

5-54

M93

Within positioning block: Coordinates are referenced to the current tool

position; effective in blocks with RO, R+, R-

.

4-l 2

M94

Limit display of rotary axis to value under 360”

.

5-55

M95

Reserved

.

M96 Reserved

.

M97 Machine small contour steps

.

5-52

M98 Completely machine open contours

.

5-53

M99 Blockwise cycle call

.

8-4

Ml69 Constant contouring speed at tool cutting edge on circular arcs

(increase and decrease feed rate)

Ml 10 Constant contouring speed at tool cutting edge on circular arcs

(feed rate decrease only)

Ml11 ResetM109/MllO

Ml26 Optimized traverse of rotary axes

Ml27 Reset Ml26

.

5-56

.

5-56

.

5-56

.

5-55

.

5-55

4

4

J

4

--

-

12-l 0

TNC 370

Loading...

Loading...