4-1

4. Maintenance of Circulation System (PXR-D, PXR-H)

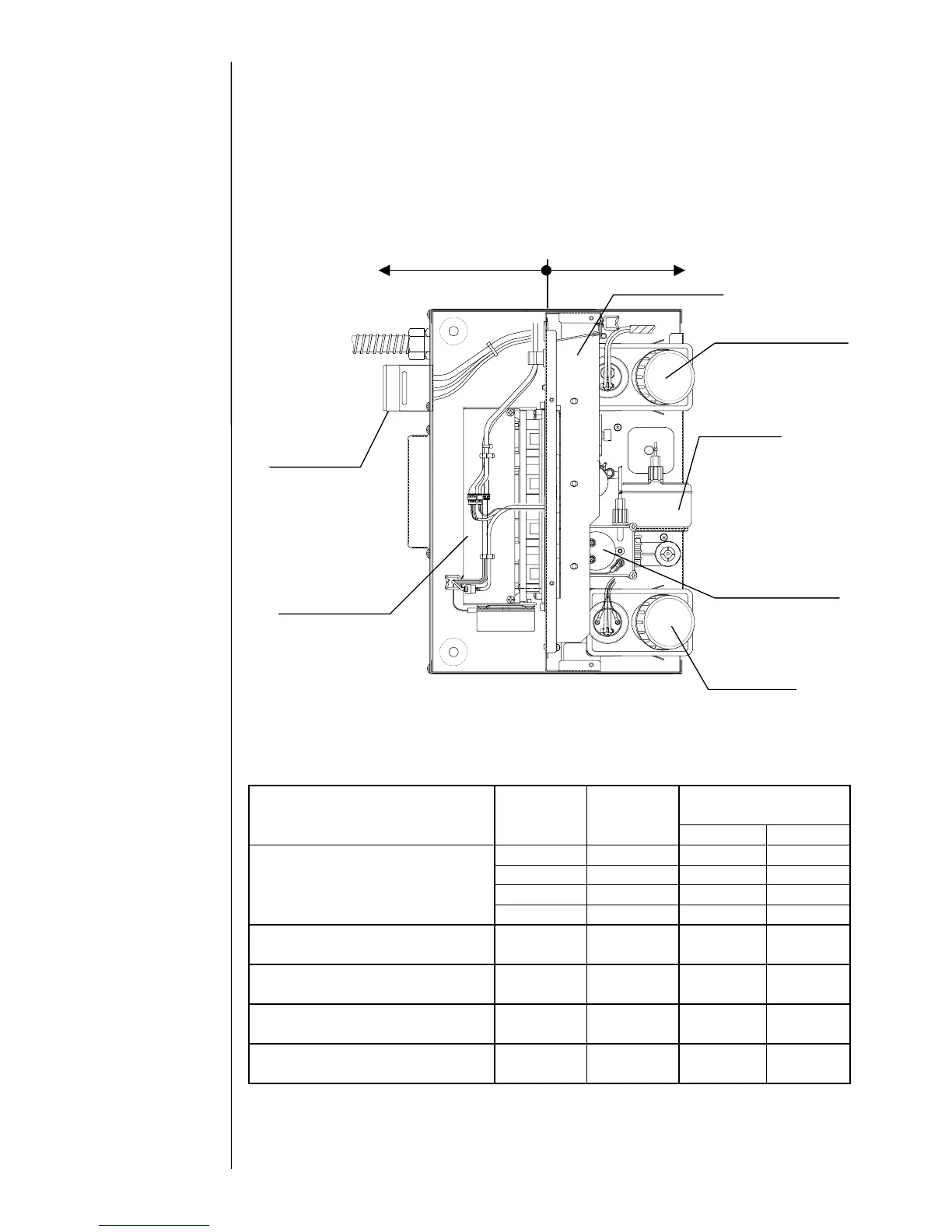

4.1 General Structure of Circulation System

4.1.1 The general structure of the circulation system is shown in the following

figure. Using an open/close type door (unit door) as a partition, the

system is roughly divided into an ink circulating area (the front side of the

equipment) and a driving part area (the rear side of the equipment).

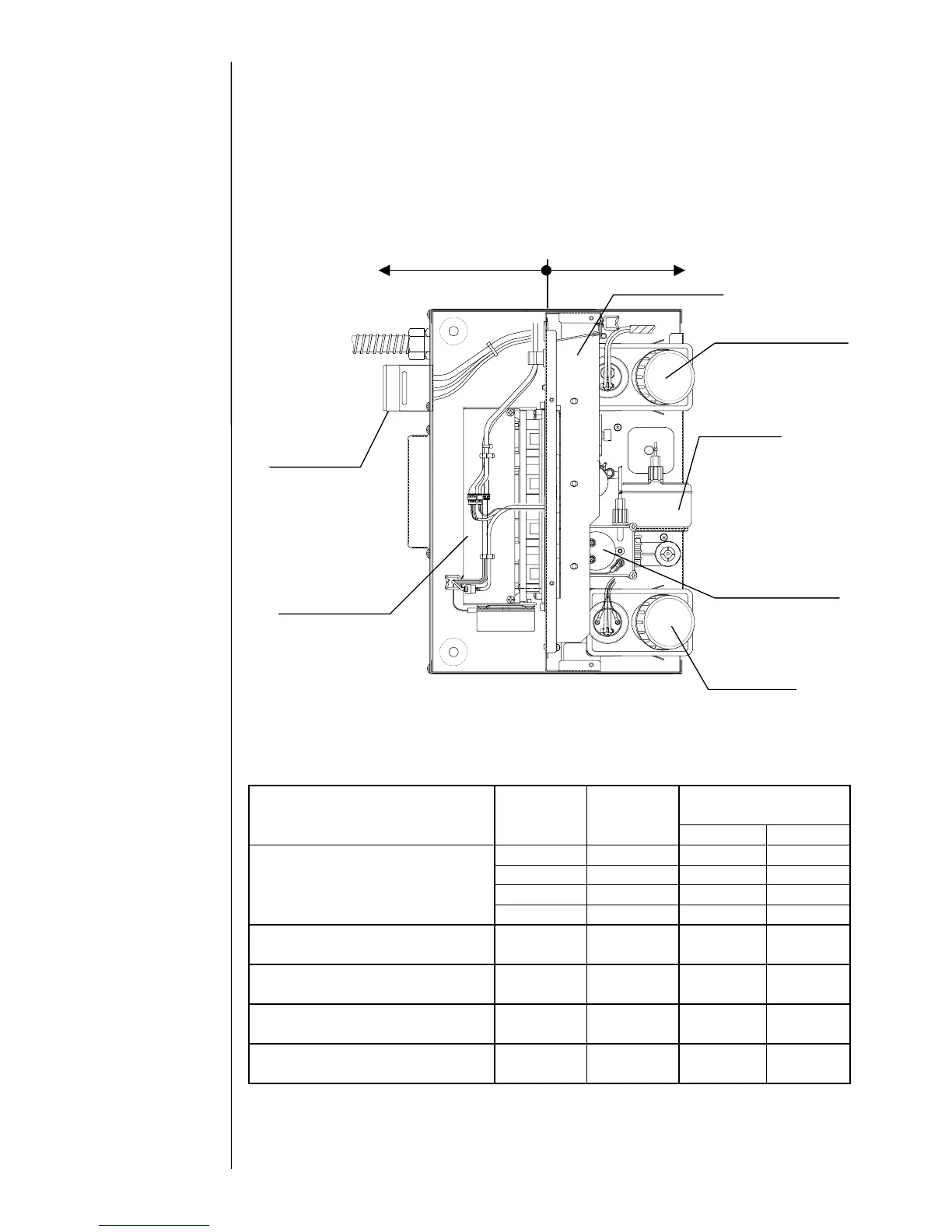

Caution:

Since the circulation unit is made of plastic, tightening the screws with excessive

torque will break the unit. See the table below for reference torques:

Reference tightening

torque

Part name (used location)

Companion

parts name

Companion

material

N·m kgf·cm

ICU base A PBT(G30) 1.7±0.3 17.3±3

ICU base B PBT(G30) 1.7±0.3 17.3±3

Front panel PP 1.33±0.22 13.6±2.2

Self-tapping screw M4X12

(attaching pressure system, etc.)

Main ink tank

PP 1.33±0.22 13.6±2.2

Self-tapping screw M4X16

(attaching solenoid valve)

ICU base B PBT(G30) 1.7±0.3 17.3±3

Self-tapping screw M4X12

(attaching pump cover)

P side plate

ADC12

(aluminum)

1.7±0.3 17.3±3

Self-tapping screw B M3X10

(attaching ICU joint)

ICU base A PBT(G30) 0.5±0.1 5.1±1

Self-tapping screw 3X8

(attaching door lock body)

Door lock

body

POM 0.75 - 1.04 7.6 - 10.6

Makeup ink reservoi

Loading...

Loading...