MC10 HS Operation - Editing Rotor Data

5 - 11

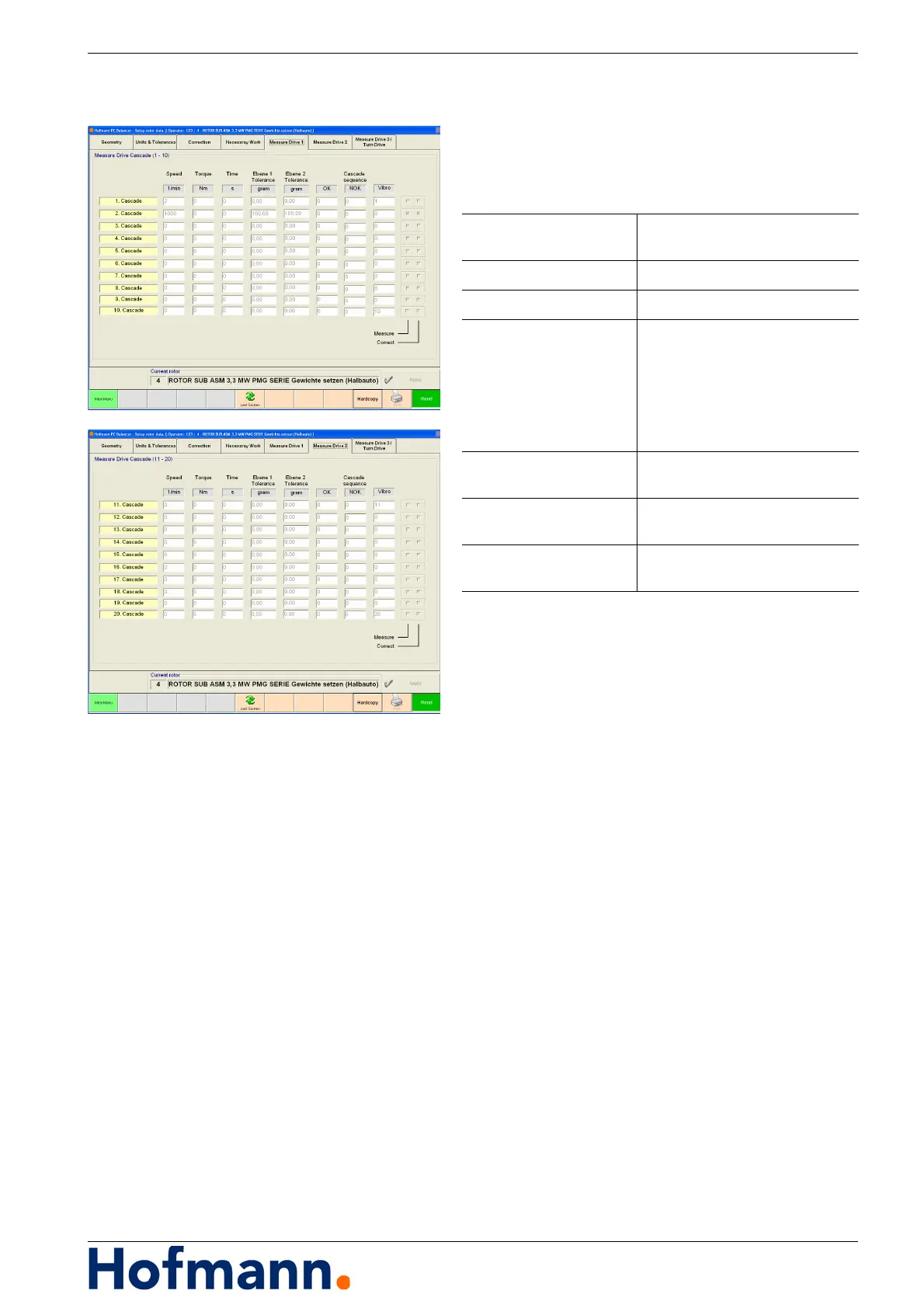

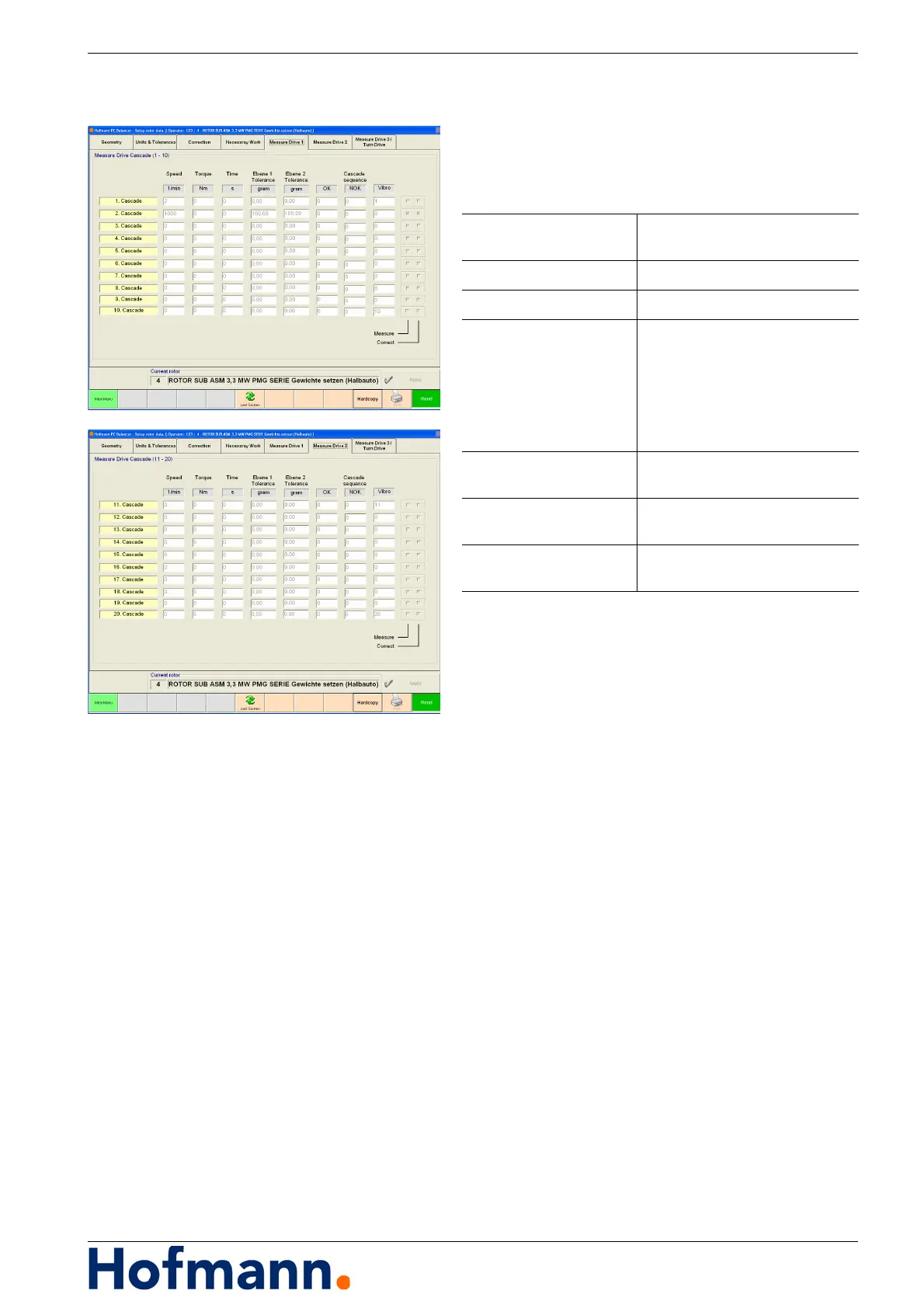

5.2.15 Setup Rotor Data - Measure Drive

Main menu \ Rotor settings.

Select „Measure Drive 1" (or 2) tab.

Enter values or change settings:

These two tabs are for setting up test runs or se-

quences of test runs.

Return if „Measure“ is ticked: Information rotor is

within/beyond the tolerance limits.

Return if „Correct“ is ticked: Information regarding the

next step is displayed, respectively information re-

garding the correction positions is sent to the ma-

chine control.

The first correction position is approached automati-

cally. Once the correction has been made the opera-

tor uses the Zustimmtaster to approach the next

correction position.

Please see Operator‘s Manual Balancing Ma-

chine, chap. 3.4.6 - Zustimmtaster

Once all corrections have been made on both the left

and right hand sides, that is, when all correction posi-

tions have been gone through, the system automati-

cally jumps to the next cascade.

Measure / Correct Choose Measure or Measure

and Correct

Speed Set nominal speed in RPM

Torque Set max. torque in Nm

Time Measure „no“: when the time en-

tered is up the system continues

with the next cascade specified

in the OK field.

Measure „yes“: the start of the

measuring run is delayed by the

time entered.

Ebene 1 Tolerance Enter tolerance in g (to define OK

or NOK).

Ebene 2 Tolerance Enter tolerance in g (to define OK

or NOK).

Cascade Sequence Enter no. of next cascade (OK or

NOK)

Loading...

Loading...